Quick Fibre Laser Welder Quote

Customer Quotation Form

When people mention CNC routers, most of us would think about cutting and engraving wood on a machine like this. However, CNC routers are also used for materials such as aluminium, brass and copper.

Whilst they will never be as efficient at processing metals when you compare them with Plasma and fibre laser technology, they can still produce projects out of these materials.

So why would you use a CNC router to cut metal?

Firstly if you already have a CNC machine, it would save you the cost of purchasing a whole new machine. Secondly, you may not have the budget to purchase another dedicated metal cutting machine to process your material, lastly, it could also be a case of not having the extra space in the workshop to have both machines.

How do you cut aluminium on a CNC router?

Firstly you have to make sure the part will be secure so having an adequate vacuum or a clamping system would be a must. This is due to the higher amounts of rotational force required to process metals.

You could also think about using a process called tabbing on your part to prevent them from moving during the final stages of the cutting path. Small tabs are added to your drawing – we use Vectric V carve for this, thus preventing parts from slipping and ultimately spoiling. Think of tabbing small parts as CNC best practice.

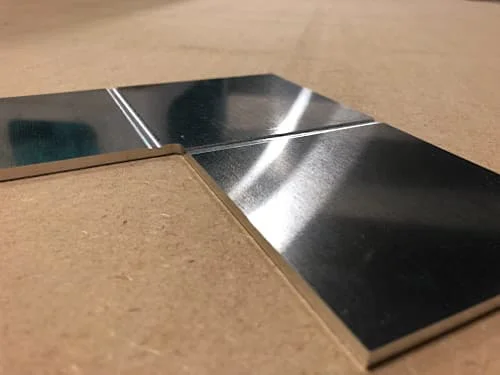

Another important part of the process is getting your tooling right for the job in hand, for example, if you are processing 3mm aluminium you need a tool that will be able to cut through (the tool length is imperative), too short it won’t cut through but equally too long the tool will flex and you won’t get the desired finish. A tool such as this cutter range called XGDA by CEC.

When cutting metal objects on a CNC the cutters and material also produce a fair bit of heat. You can dry cut but you will get a much better finish if you use a tooling lubricant that not only helps produce the best finish but also extends the life of your tooling, thus saving on costs.

If you get all of the above correct, you will be producing metal parts in no time on your CNC router.