Quick Fibre Laser Welder Quote

Customer Quotation Form

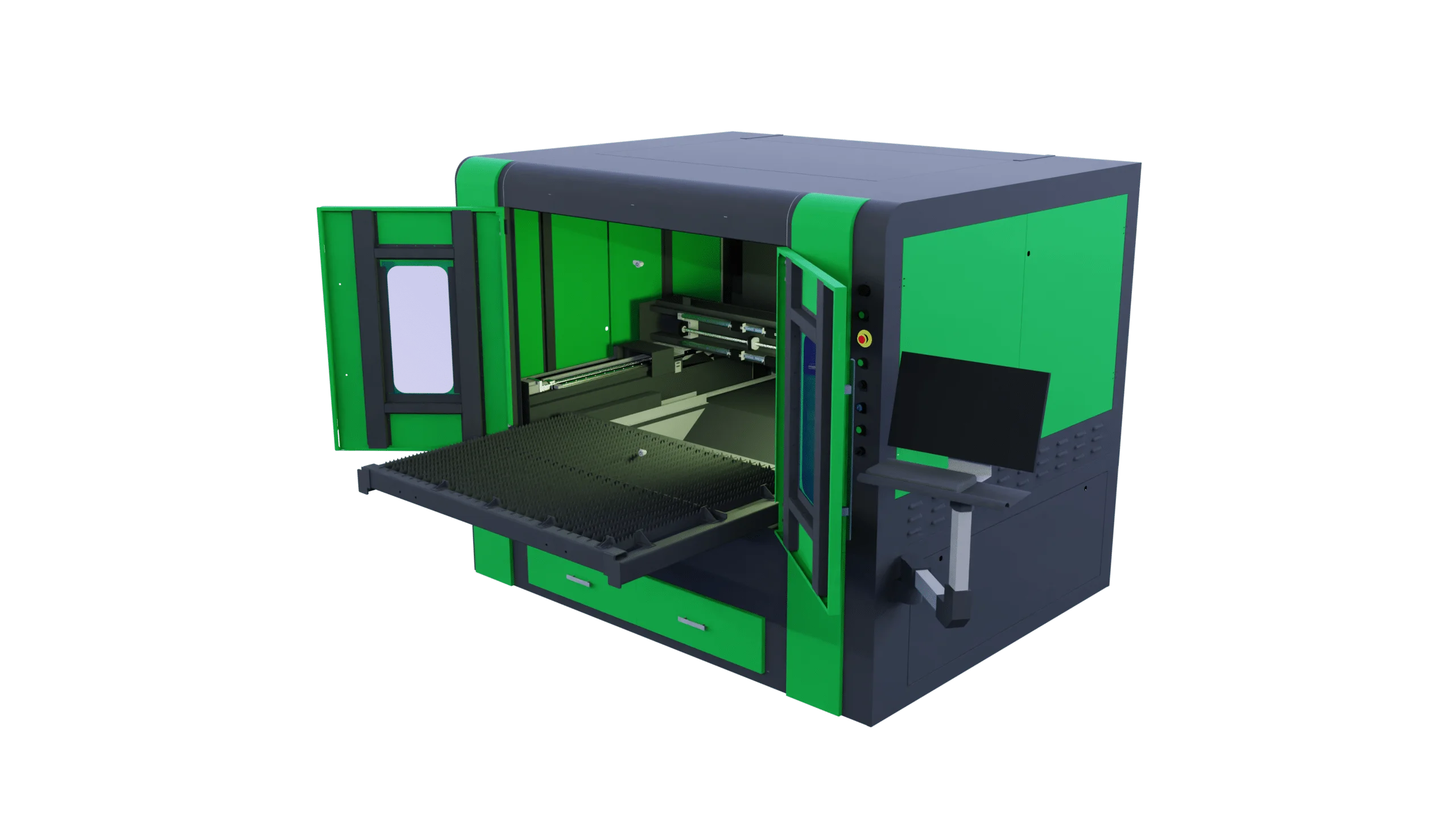

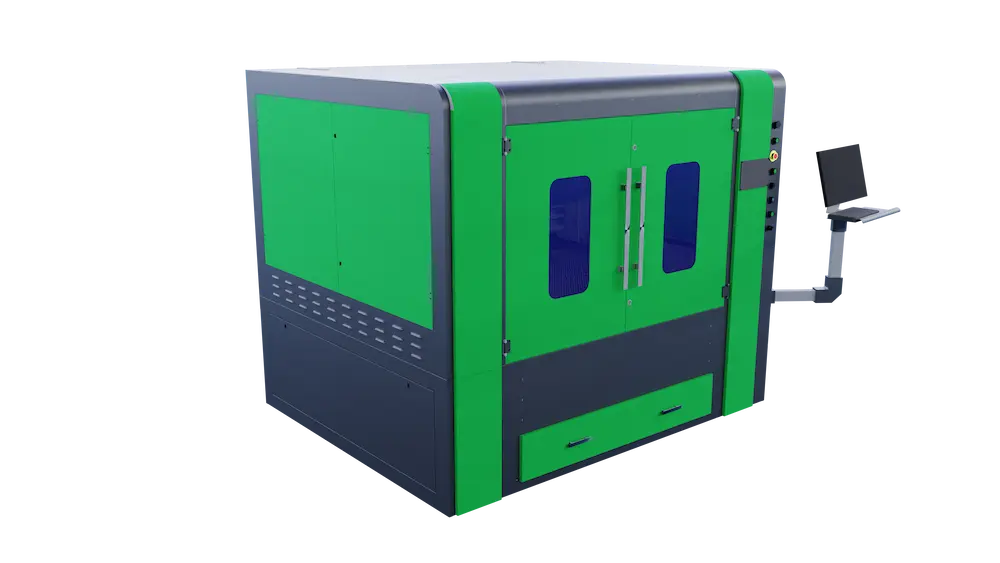

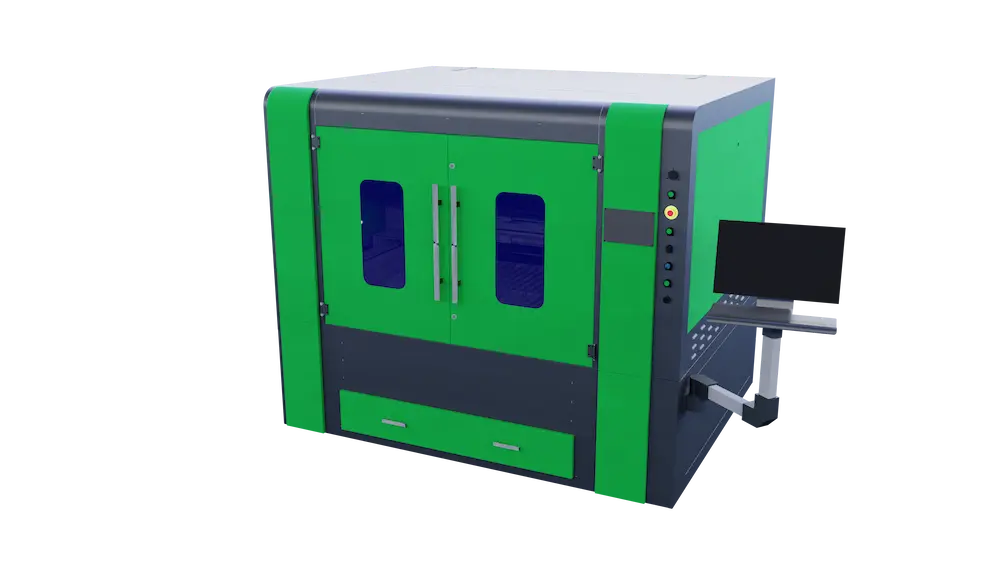

Our Titan T1 Fibre Laser Cutting Machines are Perfect for customers looking for an impressive laser for metal cutting that’s pinpoint accurate and comes with the latest included fibre laser technology.

| Topic | Details |

|---|---|

| Introduction to Titan T1 Fibre Laser Cutter Range | A compact, highly accurate fibre laser metal cutting machine with high-speed operation. Ideal for smaller workshops or engineering firms that require a smaller bed size of up to 1300*900mm. |

| Key Features | Fully enclosed laser cutter with CE-rated viewing panels. Can process carbon steel, stainless steel, brass & copper, and aluminium. Fully tested to rigorous standards. Equipped with easy-to-use controls via a Windows-based PC system and a handheld remote control pendant system. The body is rated up to 2kW, allowing for easy future upgrades. It features a compact, easy-to-manage saw tooth slat table and supports DXF file loading. It includes a dual circuit chiller, an autofocus cutting head, scrap draws, and comes with all necessary software. |

| Service | All Titan T1 Fibre Lasers are fully tested to rigorous standards at the company’s headquarters facility in the West Midlands. After-sales service is UK based and available to all customers if needed. Lifetime technical support via email and telephone is included. |

| Applications | Used in a wide range of sectors such as marine engineering, mechanical fabrication, steel fabrication, construction, automotive manufacturing, sign making, aerospace engineering, electrical component manufacturing, and education engineering departments. |

| Safety & Build Quality | The machine is fully enclosed to ensure the safety of the operator and bystanders and comes with CE-rated laser viewing glass. It is built to industrial quality standards and comes with an excellent 24-month parts and labour warranty (consumables not included). |

| Summary of Titan T1 Fibre Laser Cutter Range | The machine is fully enclosed to ensure the safety of the operator and bystanders and comes with CE-rated laser viewing glass. It is built to industrial quality standards and comes with excellent 24-month parts and labour warranty (consumables not included). |

Fibre laser light energy is created by banks of diodes. The light is transferred through a special fibre optic cable, an efficient energy transfer compared to conventional methods. The light, upon exiting the fibre cable, is then collimated (straightened) as it approaches the focus lens – which intensifies the beam enabling it to cut through the material with astonishing speed and accuracy

Raytools cutting head with high-performance non-contact capacitive height sensor is used and is designed to withstand high ‘gas assist’ pressures. The proven lens cartridge change system makes switching lenses for different materials or applications fast & simple. A. High cutting speed with the best cutting quality B. Quick change-over between three focal lengths without changing the TCP (Tool Centre Point) C. Protective window (lens) can be replaced as a consumable part, to extend the life of the focusing lens.

A. Dual function intelligent cooling system, specifically designed for fibre laser machines, ensuring the efficient operation of laser cutting head and laser source B. ±0.3°C Precise temperature control. C. Multiple alarm functions: compressor time-delay protection, compressor over current protection, water flow alarm and high/low-temperature alarm. D. Full CE approval, RoHS approval, REACH approval.

Precise positioning & repeat-ability with ‘Double Y Axis’ Taiwanese TBI Ball screw system.

Closed loop AC servo drive system and servomotors to ensure high dynamics, vibration- free operation and maximum precision

A. Power Automation CNC Control with integrated I/O

B. Each system is equipped with an HMI (Human Machine Interface). With this open, browser-based all important control functions are clearly represented to the operator, so it will work within the shortest training time efficiently and safely with the CNC system.

C. The CNC Systems are equipped with high-speed processors to accomplish an extremely fast ‘Block Throughput”. Highly accurate contours with very small NC blocks can be processed without any loss of speed. Therefore, the machine always reaches its highest productivity.

D. Cypcut laser cutting control system Support AI, DXF, PLT and other graphic data formats CAD module/nesting + processing function.

| Titan T1 Fbre Laser Cutter | Information |

|---|---|

| Safety Enclosure | Yes – full safety enclosure to protect your operators from any stray beams and to aid in the safe extraction of cutting vapour. |

| Bed Sizes | 1300 x 900 mm |

| Laser Source Options | 1.5kW, 2kW |

| Cutting Head | Raytools – Autofocus |

| Servo Motors | Yes – Yaskawa |

| Drive System | Double Y Axis ball screw transmission |

| Guide Rails | HIWIN |

| Ball Screw | TBI |

| Water Chiller | Yes – S&A CWFL Series (model, laser source dependent) |

| CNC Control | Cypcut |

| Software package | Cypcut laser cutting control system |

| Work Table Type | Blade saw worktable |

| Consumables | X6 nozzles, X6 protective lenses, X1 focusing lens |

| Power requirements | 3 Phase AC 380V 50HZ |

| Delivery | Included (offloading and positioning are available upon request) |

| Installation & Training | Included |

| Material | 1.5kW | 2kW |

|---|---|---|

| Carbon Steel | 14mm (max) | 18mm (max) |

| Stainless Steel | 6mm (max) | 8mm (max) |

| Aluminium Alloy | 4mm (max) | 5mm (max) |

| Brass | 3mm (max) | 4mm (max) |

| Copper | 3mm (max) | 3mm (max) |