Szybka wycena spawacza laserowego światłowodowego

Formularz wyceny klienta

Formularz wyceny klienta

Formularz wyceny klienta

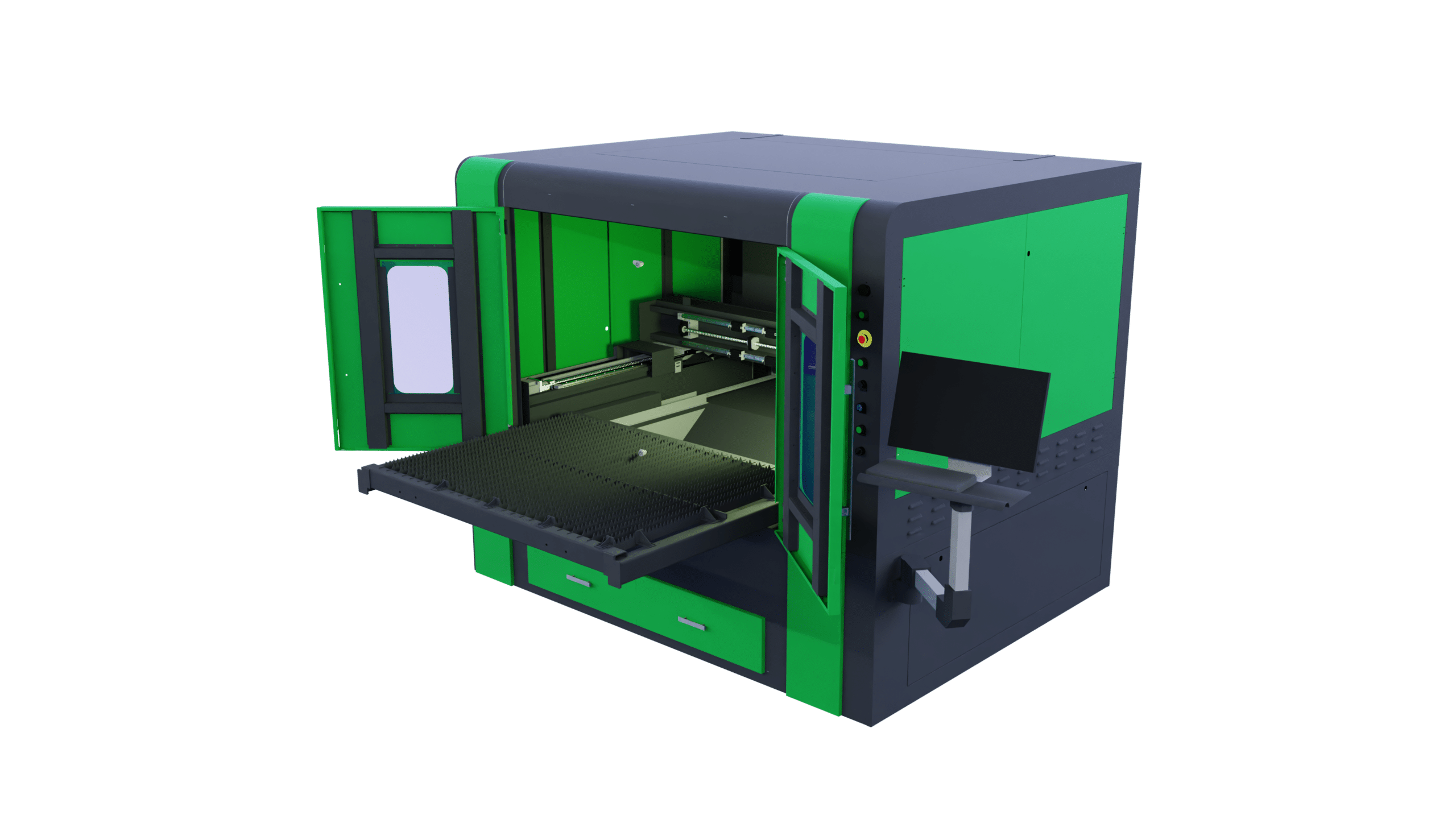

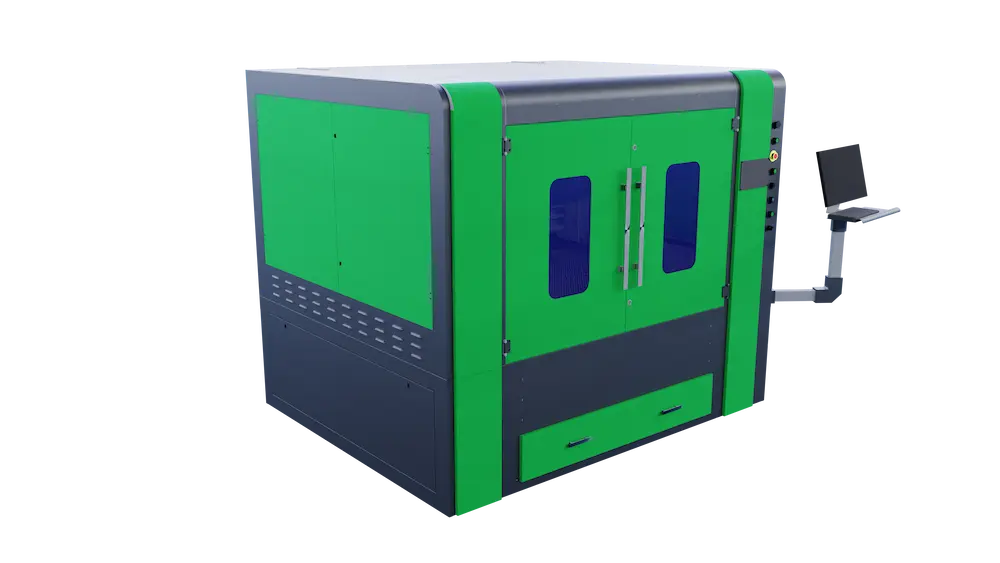

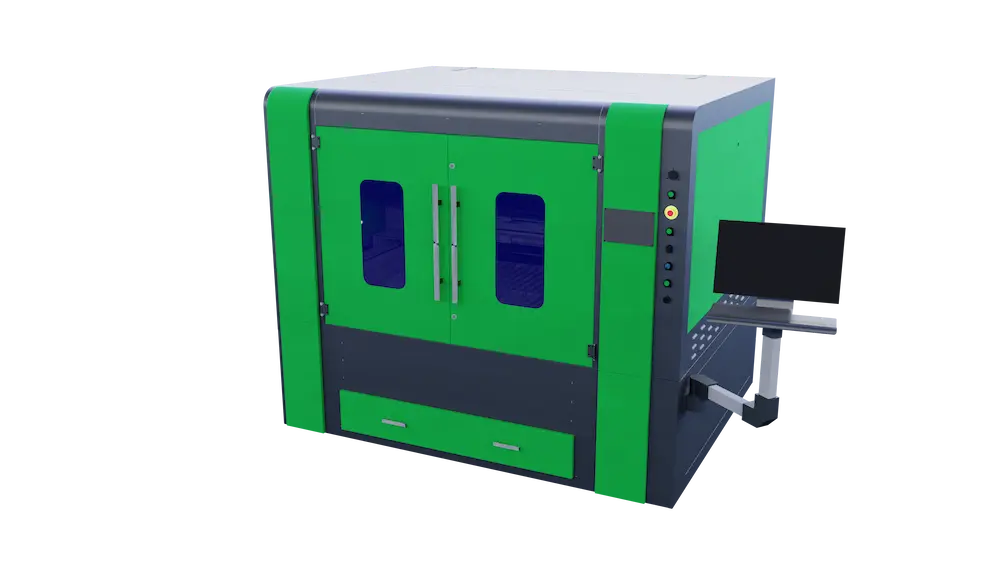

Autonomiczne Maszyny do cięcia laserem światłowodowym Titan T1 są idealne dla klientów poszukujących imponującego lasera do cięcia metalu, który jest niezwykle dokładny i wyposażony w najnowszą technologię lasera światłowodowego.

| Temat | Szczegóły |

|---|---|

| Wprowadzenie do gamy ploterów tnących z laserem światłowodowym Titan T1 | Kompaktowa, bardzo dokładna maszyna do cięcia metalu laserem światłowodowym o dużej szybkości działania. Idealny dla mniejszych warsztatów lub firm inżynieryjnych, które wymagają mniejszego łóżka o wymiarach do 1300*900 mm. |

| Podstawowe dane | Całkowicie zamknięta wycinarka laserowa z panelami widokowymi z certyfikatem CE. Może przetwarzać stal węglową, stal nierdzewną, mosiądz i miedź oraz aluminium. W pełni przetestowane zgodnie z rygorystycznymi normami. Wyposażony w łatwe w użyciu elementy sterujące za pośrednictwem systemu komputerowego z systemem Windows i podręczny system zdalnego sterowania. Nadwozie ma moc znamionową do 2 kW, co pozwala na łatwą rozbudowę w przyszłości. Posiada kompaktowy, łatwy w obsłudze stół z listwami piły i obsługuje ładowanie plików DXF. Zawiera dwuobwodowy agregat chłodniczy, głowicę tnącą z autofokusem, układ pobierania złomu i całe niezbędne oprogramowanie. |

| Usługi | Wszystkie lasery światłowodowe Titan T1 są w pełni testowane zgodnie z rygorystycznymi normami w siedzibie firmy w West Midlands. Obsługa posprzedażna ma siedzibę w Wielkiej Brytanii i jest dostępna dla wszystkich klientów w razie potrzeby. Dożywotnia pomoc techniczna przez e-mail i telefon jest wliczona w cenę. |

| Konsultacje | Używany w wielu sektorach, takich jak inżynieria morska, produkcja mechaniczna, produkcja stali, budownictwo, produkcja samochodów, szyldy, inżynieria lotnicza, produkcja komponentów elektrycznych i wydziały inżynierii edukacyjnej. |

| Bezpieczeństwo i jakość wykonania | Maszyna jest całkowicie zamknięta, aby zapewnić bezpieczeństwo operatora i osób postronnych, i jest wyposażona w szkło laserowe z certyfikatem CE. Został zbudowany zgodnie z przemysłowymi standardami jakości i jest objęty doskonałą 24-miesięczną gwarancją na części i robociznę (bez materiałów eksploatacyjnych). |

| Podsumowanie gamy wycinarek laserowych Titan T1 | Maszyna jest całkowicie zamknięta, aby zapewnić bezpieczeństwo operatora i osób postronnych, i jest wyposażona w szkło laserowe z certyfikatem CE. Został zbudowany zgodnie z przemysłowymi standardami jakości i jest objęty doskonałą 24-miesięczną gwarancją na części i robociznę (bez materiałów eksploatacyjnych). |

Energia światła lasera światłowodowego jest tworzona przez banki diod. Światło jest przenoszone przez specjalny kabel światłowodowy, co zapewnia wydajny transfer energii w porównaniu z konwencjonalnymi metodami. Światło wychodzące z kabla światłowodowego jest następnie kolimowane (prostowane) w miarę zbliżania się do soczewki skupiającej – co wzmacnia wiązkę, umożliwiając przecinanie materiału z zadziwiającą szybkością i dokładnością

Zastosowano głowicę tnącą Raytools z wysokowydajnym bezdotykowym pojemnościowym czujnikiem wysokości, która została zaprojektowana tak, aby wytrzymać wysokie ciśnienie „wspomagania gazem”. Sprawdzony system wymiany wkładów obiektywowych sprawia, że zmiana soczewek do różnych materiałów lub zastosowań jest szybka i prosta. A. Wysoka prędkość cięcia przy najlepszej jakości cięcia B. Szybkie przełączanie pomiędzy trzema ogniskowymi bez zmiany TCP (Tool Center Point) C. Okienko ochronne (soczewkę) można wymienić jako część eksploatacyjną, aby wydłużyć żywotność soczewka skupiająca.

A. Dwufunkcyjny inteligentny system chłodzenia, zaprojektowany specjalnie dla maszyn z laserem światłowodowym, zapewniający wydajną pracę głowicy tnącej i źródła lasera B. ±0.3°C Precyzyjna kontrola temperatury. C. Wiele funkcji alarmowych: zabezpieczenie opóźnienia sprężarki, zabezpieczenie nadprądowe sprężarki, alarm przepływu wody i alarm wysokiej/niskiej temperatury. D. Pełna aprobata CE, aprobata RoHS, aprobata REACH.

Precyzyjne pozycjonowanie i powtarzalność dzięki tajwańskiemu systemowi śrub kulowych TBI z podwójną osią Y.

System serwonapędów prądu przemiennego z zamkniętą pętlą i serwomotory zapewniają wysoką dynamikę, pracę bez wibracji i maksymalną precyzję

A. Sterowanie CNC Power Automation ze zintegrowanymi wejściami/wyjściami

B. Każdy system jest wyposażony w HMI (Human Machine Interface). Dzięki temu otwartemu, opartemu na przeglądarce, wszystkie ważne funkcje sterowania są jasno przedstawione operatorowi, dzięki czemu będzie działać wydajnie i bezpiecznie w najkrótszym czasie szkolenia z systemem CNC.

C. Systemy CNC są wyposażone w szybkie procesory, aby osiągnąć niezwykle szybką „przepustowość bloku”. Bardzo dokładne kontury z bardzo małymi blokami NC mogą być przetwarzane bez utraty prędkości. Dzięki temu maszyna zawsze osiąga najwyższą wydajność.

D. System sterowania cięciem laserowym Cypcut Obsługuje AI, DXF, PLT i inne formaty danych graficznych Moduł CAD/zagnieżdżanie + funkcja przetwarzania.

| Wycinarka laserowa Titan T1 Fbre | Informacja |

|---|---|

| Obudowa bezpieczeństwa | Tak — pełna osłona zabezpieczająca, która chroni operatorów przed wszelkimi rozproszonymi wiązkami i pomaga w bezpiecznym odprowadzaniu oparów powstających podczas cięcia. |

| Rozmiary łóżek | 1300 x 900 mm |

| Opcje źródła laserowego | 1.5 kW, 2 kW |

| Głowica tnąca | Raytools – autofokus |

| Silniki serwo | Tak – Yaskawa |

| system napędowy | Przekładnia śrubowa z podwójną osią Y |

| Prowadnice | HIWIN |

| Screw Ball | TBI |

| Agregat wody | Tak — seria S&A CWFL (model, w zależności od źródła lasera) |

| Sterowanie CNC | Cyprcut |

| Pakiet oprogramowania | System kontroli cięcia laserowego Cypcut |

| Typ stołu roboczego | Stół roboczy piły tarczowej |

| Materiały eksploatacyjne | Dysze X6, soczewki ochronne X6, soczewka skupiająca X1 |

| Wymagania dotyczące zasilania | 3 fazy AC 380 V 50 Hz |

| Dostawa | W cenie (rozładunek i pozycjonowanie są dostępne na życzenie) |

| Instalacja i szkolenie | w zestawie |

| Materiał | 1.5kW | 2kW |

|---|---|---|

| Stal węglowa | 14mm (maks.) | 18mm (maks.) |

| Stal nierdzewna | 6mm (maks.) | 8mm (maks.) |

| Aluminiowa | 4mm (maks.) | 5mm (maks.) |

| Mosiądz | 3mm (maks.) | 4mm (maks.) |

| Miedź | 3mm (maks.) | 3mm (maks.) |