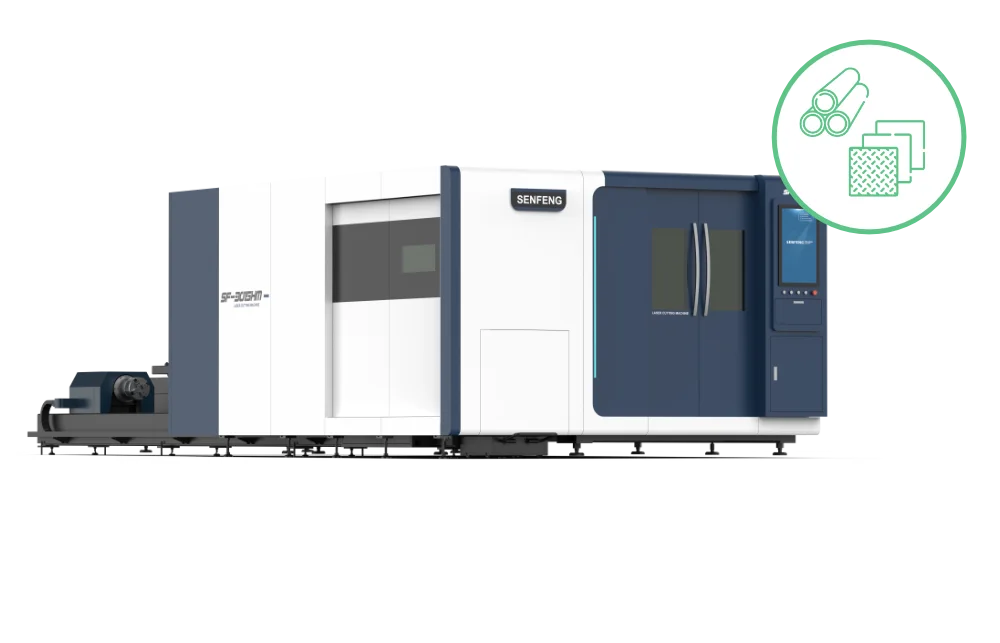

Versatile Combination Fibre Laser Cutter - Sheet & Tube Cutting in One Machine

The SF Combination Fibre Laser Cutter is a high-performance dual-function system, that seamlessly integrates flat plate and tube cutting in a single machine. Designed for maximum flexibility and efficiency, it enables businesses to process sheet metals and tubes effortlessly, reducing downtime and streamlining production workflows.

Multi-Purpose Fibre Laser Cutter for Sheet & Tube Processing

The SF Combination Fibre Laser Cutter is designed for maximum versatility, effortlessly handling both flat sheet and tube cutting to meet diverse manufacturing demands.

Optimised Space-Saving Design

By integrating plate and tube cutting into one compact system, this machine eliminates the need for multiple units, freeing up valuable workshop space.

High-Precision Cutting with Intuitive Controls

Delivering exceptional accuracy across both sheet metal and tubular materials, this system ensures consistent results while its user-friendly interface makes operation simple and efficient.

Full UK Warranty

Delivery Included

Installation Included

1.5-6kW Power Options

Flat Plate & Tube Cutting

Dual Purpose Fibre Laser - Cut Both Sheet & Tube with One System

The SENFENG 3015HM is a high-performance metal-cutting solution that seamlessly combines flat sheet and tube processing in a single, compact system.

Intuitive Control & Advanced Software

The SF Fibre Laser range is equipped with the powerful Cypcut PC-based control system—an integrated CAD/CAM solution that streamlines the cutting process, ensuring precision and efficiency at every stage.

High-Powered & Versatile Cutting

Offering power configurations from 1.5kW to 6kW, the SF Combination Fibre Laser Cutter is designed for a wide range of industrial applications, delivering outstanding performance and adaptability for complex manufacturing needs.

Precision Auto-Focus Cutting System

Fitted with high-performance RayTools cutting heads, each machine features built-in capacitance height sensors and an advanced autofocus function, allowing for seamless material transitions and optimal cutting accuracy.

Fully Enclosed System for Safety

6 mtr Rotary Indexer for Tube and Profile Cutting

Full Control With The Included PC System

Dual Shuttle Exchange Tables

Powerful Cutting Options from 1.5-6kW

Fully Enclosed for Maximum Safety

Every SF Fibre Laser Cutter is housed within a fully enclosed structure, safeguarding operators and other personnel from laser radiation and airborne metal particulates while maintaining a clean, controlled workspace.

Laser-Certified Viewing Panels

Designed with operator safety in mind, our machines include CE-rated laser-safe viewing panels, allowing for clear process monitoring without exposure to harmful laser emissions.

Industry-Leading Support & Service

Our expert UK-based support team offers dedicated telephone assistance, on-site service engineers, and an extensive online support portal with troubleshooting guides, ensuring you receive the highest level of after-sales care.

SF Combination Fibre Laser Cutter - Precision & Versatility in One Machine.

The SF Combination Fibre Laser Range is designed for manufacturers who need both flat sheet and tube cutting in a single, high-performance system. With advanced technology, powerful cutting capabilities, and seamless material transition, this range redefines efficiency and versatility in metal fabrication.

Effortless Operation & Precision Control

The SF Fibre Laser Cutter features an intuitive Windows-based PC control system and a handheld remote pendant, offering seamless operation, cloud connectivity, and advanced networking for efficient workflow management.

Scalable Cutting Power for Maximum Flexibility

Available with laser power options from 1.5kW to 6kW, the SF Combination Fibre Laser Cutter is designed to handle a wide range of materials and thicknesses, delivering superior cutting performance for demanding industrial applications.

Dual Shuttle Exchange Tables for Continuous Production

The dual-table shuttle exchange system maximises efficiency by allowing material loading and unloading while the machine operates, significantly reducing downtime and increasing productivity.

Integrated Rotary Index for Tube & Pipe Cutting

Enhance versatility with the built-in rotary indexer, allowing seamless transition between sheet metal and tube cutting, optimising efficiency for mixed-material production.

High-Speed File Processing for Instant Cutting

The advanced Cypcut control software enables direct DXF file loading without post-processing, allowing instant cutting with minimal setup time—ideal for rapid prototyping and short-run production.

Advanced Dual-Circuit Chiller for Optimal Cooling

Every SF Fibre Laser is equipped with an S&A dual-circuit chiller, maintaining optimal operating temperatures for both the laser power source and optical components, ensuring long-term reliability.

Wireless Remote Control for Enhanced Usability

The ergonomic handheld remote provides precise machine control, including head positioning, shutter control, assist gas adjustments, and speed settings, improving workflow convenience.

Precision Auto-Focus Cutting Head

Standard RayTools cutting heads feature capacitance height sensors and auto-focus functionality, enabling effortless cutting transitions across multiple material types and thicknesses.

Fully Enclosed Safety Design for Maximum Protection

The enclosed fibre laser system ensures operator safety by containing laser radiation and metal particulates, maintaining a clean and secure working environment.

Certified Laser-Safe Viewing Panels

CE-rated viewing windows allow operators to safely monitor the cutting process without exposure to harmful laser emissions, ensuring compliance with industry safety regulations.

Comprehensive CAD/CAM Software Suite

Included software provides advanced features such as automatic nesting, parametric part libraries, fly-cutting, common edge cutting, and kerf compensation for precise, optimised cutting.

High-Efficiency Cyclone Extraction System

Optional Cyclone extraction units are available for installation indoors or outdoors, effectively removing fumes and particulates to maintain a clean workspace.

User-Friendly Scrap Collection Drawers

Lightweight, easy-to-pull-out scrap drawers simplify the disposal of waste materials, improving workflow efficiency and maintaining a clutter-free cutting area.

Dedicated UK Engineering & Support Teams

Our experienced UK-based engineers provide full installation, training, and lifetime support, ensuring your machine delivers maximum performance from day one.

Industry-Leading 24-Month Warranty

All SF Fibre Laser Cutters include a comprehensive two-year parts and labour warranty (excluding consumables), providing peace of mind and long-term reliability.

Expert After-Sales Service & Lifetime Support

We offer dedicated UK-based after-sales support, including telephone and email assistance, ensuring you receive expert help whenever needed to keep operations running smoothly.

Overview and Features

| SF HM Combination Fibre Laser Datasheet | Description |

|---|---|

| Cutting table sizes | 3050 x 1530 | 4050 x 2030 | 6050 x 1530 | 6050 x 2030 | 6050 x 2530 |

| Table type | Low contact cutting table |

| Shuttle Exchange Table | Yes - dual shuttle exchange tables included |

| Laser Power Options | 1.5kW | 3kW | 6kW options |

| Rotary Indexer | Yes - 6m module |

| Positioning Accuracy (X,Y axis) | ±0.05 mm |

| Repeat Positioning Accuracy (X,Y axis) | ±0.02 mm |

| Max Speed | 130 m/min |

| Max Acceleration | 1.0G |

| Safety Enclosure | Yes – full safety enclosure to protect your operators from any stray beams and to aid in the safe extraction of cutting vapour |

| Laser Cutting Head | Raytools - Autofocus |

| Servo Drives | High-accuracy servo-driven system |

| Drive System | Double Y axis ball screw transmission |

| Guide Rails | HIWIN guide rails |

| Ball Screw | TBI ball screw |

| Dual Channel Water Chiller | Yes - S&A CWFL Series (model is power dependant) |

| CNC Controller | Cypcut CNC control |

| Software Included | Yes - integrated CAD package for on-machine file creation/editing |

| Consumables | Yes - set of protective lens, focus lens, and nozzle pack supplied (additional available to purchase) |

| Power requirements | 3 Phase AC 380V 50HZ |

| Delivery and installation | Included (offloading and positioning are available upon request). Installation and training included |

| Chiller Dimensions | S&A Model to Suite |

| Length | 550 mm |

| Depth | 770 mm |

| Height | 1030 mm |

| Weight | Appx 95kg |

Why Choose The SF HM Combination Fibre Laser Range?

The SF HM Combination Fibre Laser Cutter is a high-performance, dual-purpose system designed to streamline fabrication by integrating flat plate and tube cutting within a single machine. This versatile solution eliminates the need for multiple machines, optimising workflow and maximising productivity for manufacturers in metal processing, engineering, and industrial production.

Multi-Functionality for Enhanced Efficiency

- Seamlessly switch between sheet metal cutting and tube/profile processing, improving efficiency and reducing production time.

- Compact footprint saves valuable workshop space while delivering high-powered cutting performance.

- Advanced user-friendly software ensures precise control and optimised cutting for various materials and thicknesses.

Engineered for Industrial-Grade Performance

- Cutting power options from 1.5kW to 6kW cater to a wide range of fabrication needs.

- Built with high-quality components and a durable design for long-term reliability.

- Fast shuttle exchange table enables continuous cutting and minimal downtime.

- Available in multiple bed sizes to suit specific production requirements.

Safe & Efficient Operation

- Fully enclosed design ensures a safe working environment by containing laser emissions and metal particulates.

- Integrated fume extraction system effectively removes hazardous vapours, maintaining workplace safety.

Is Training and Delivery Included?

Yes, all of our Fibre Laser Cutters include UK mainland delivery as standard. We also provide comprehensive operator training to ensure you can confidently run your new machine from day one.

*Note: This list is not exhaustive. Always check with your materials supplier to see if you need to adhere to any special cutting and health and safety requirements.

| Metals |

|---|

| Stainless Steel |

| Mild and Carbon Steel |

| Copper |

| Brass |

| Aluminium |

| Titanium |

Request a Quick Quotation

Ask us for a machinery quotation using our easy-to-fill form below.

Keep up with the Latest

Fibre Laser Installations

Jun 23rd

3 weeks ago

Vector FL300 Fibre Laser Installed in Braughing

Jun 16th

4 weeks ago

Vector FL250 Fibre Laser Installed – Power Meets Precision

May 20th

2 months ago

Lasertech 90130 Laser Cutter Installed at UK School – Supporting STEM Learning

Apr 10th

3 months ago

Installation Update – Vector FL90 Fibre Laser in London

Apr 7th

3 months ago

Precision Meets Education – Vector FL90 Installed in Edinburgh

Apr 7th

3 months ago