High Performance Fibre Laser Welders. Precision & Efficiency.

Energy-Efficient Welding Technology

High-Powered Welding Performance

Reliable & Low-Maintenance Operation

Multi-Material Compatibility for Maximum Versatility

Intuitive User Interface for Seamless Operation

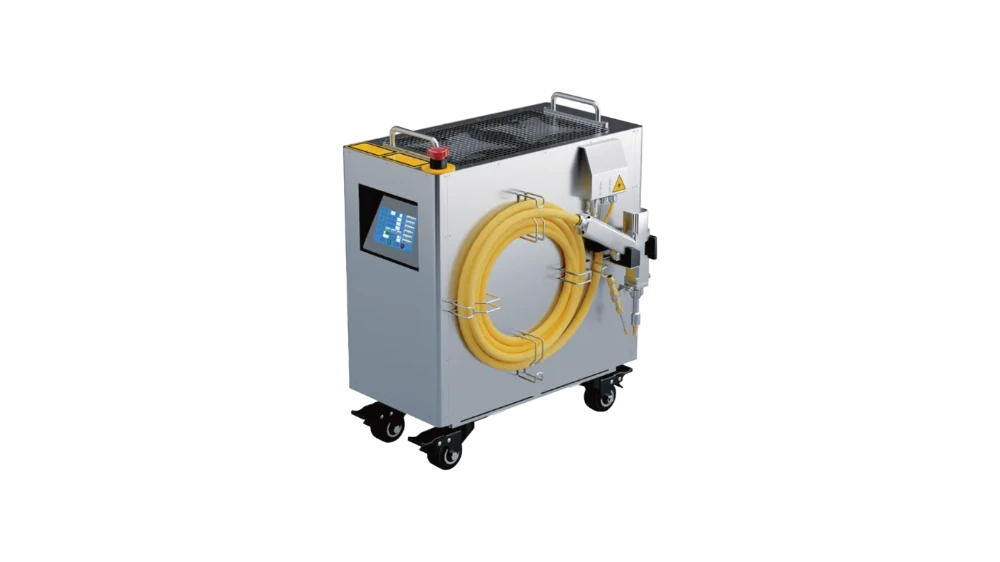

Compact, Space-Saving & Built to Last

UK Warranty (RTB)

Upto 2kW Power

Air Cooled

Touchscreen

Easy to Operate

Transform Your Welding & Fabrication Process

Effortless Welding with Fibre Laser Technology

RECI Fibre Laser Welders - Precision & Efficiency Redefined

Essential Laser Welding Safety Tips and Guidence

For a safe and controlled laser welding environment, it is vital to use a laser-specific safety enclosure that isolates the welding unit and operators from the rest of the workshop. This ensures compliance with safety standards while maintaining a secure workspace.

Key Safety Measures:

- Proper Fume Extraction: Install a dedicated extraction system within the enclosure to maintain air quality and remove hazardous fumes.

- Personal Protective Equipment (PPE): Operators must wear welding gloves, safety coveralls, and a welding helmet with a laser-rated viewing panel for eye protection.

- Laser Safety Eyewear: In addition to the welding mask, operators should use laser safety eyewear for maximum protection against laser exposure.

- Compliance with Class 4 Laser Safety Regulations: Follow all relevant safety protocols, risk assessments, and operator training as required for high-powered laser equipment.

This guidance serves as a basic overview of best practices for laser welding safety. It is essential to comply with local health and safety regulations and ensure all personnel are fully trained on potential hazards and required precautions.

Overview and Features

| RECI Laser Welders Datasheet | A80 | A120 | A150 | A200 | |||

|---|---|---|---|---|---|---|---|

| Limit Output Power (W) at 19A | 700 | 1000 | 1300 | 2000 | |||

| Max Output Power (W) at 22.5A | 800 | 1200 | 1500 | 2200 | |||

| Operating Mode | Continuous | ||||||

| Power range | 10-100 | ||||||

| Central Wavelength | 1080 ±3 | ||||||

| Laser Class | Class 4 Laser (health and safety precautions apply) | ||||||

| Power Instability (% during continuous operation of 1hr) | ≤1 | ||||||

| Power Instability (% during environmental conditions from 0-40 deg˚) | ≤3 | ||||||

| Max Modulation Frequency (kHz) | 20 | ||||||

| Red Dot Laser Power (mW) | >0.5 | ||||||

| Operating Cable Length (m) | 5 as standard (10 optional) | ||||||

| Operating Voltage | AC 220V 50/60Hz | ||||||

| Power Consumption (W) | <2500 | <3000 | <4000 | <6000 | |||

| Control Mode | Ext. AD/Loc. AD | ||||||

| Weight (kg) | -5 - 40˚ | ||||||

| Abient Humidity (%) | <90 | ||||||

| Cooling Method | Air Cooled system | ||||||

| Storage Temp Range (˚C) | -10 - 40˚ | ||||||

| Input Gas Pressure (Mpa) | <0.7 | ||||||

| Dimensions Width x Depth x Height (mm) | 273x615x396.3 | 273x635x528 | 273x635x528 | 273x635x668 | |||

Why Choose The RECI Fibre Laser Welder Range?

The RECI Fibre Laser Welder Range is engineered for precision, efficiency, and reliability, making it the ultimate solution for industrial and commercial welding applications. Featuring power options from 800W to 2kW, these advanced laser welders provide the versatility needed to handle a wide variety of materials, including stainless steel, aluminium, carbon steel, and copper.

Unmatched Precision & Efficiency

RECI Fibre Laser Welders deliver high-quality, seamless welds with minimal heat distortion, ensuring stronger, cleaner joints across different material thicknesses. The high-speed operation significantly reduces production times, making it ideal for high-output manufacturing environments.

User-Friendly & Space-Saving Design

- Intuitive Touchscreen Controls – Easy-to-use interface for seamless operation, even on complex welding tasks.

- Compact & Durable Build – Space-efficient design that fits into any workshop or production line.

- Low Maintenance & Energy Efficient – Cost-effective operation with minimal maintenance requirements.

A Smart Investment for Industrial Welding

Backed by a proven reputation for reliability, the RECI Fibre Laser Welding Range is designed to enhance productivity while minimising operational costs. Whether you’re in automotive, aerospace, fabrication, or manufacturing, these high-performance welding systems provide the precision, speed, and durability needed to take your production to the next level.

| Metals |

|---|

| Stainless Steel |

| Mild and Carbon Steel |

| Copper |

| Brass |

| Aluminium |

| Titanium |