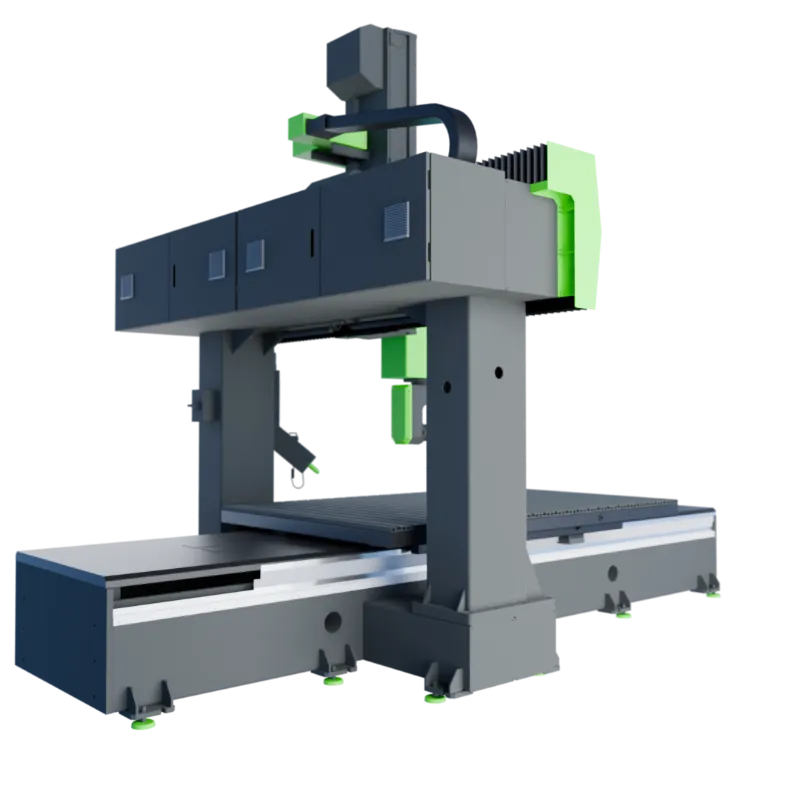

5 Axis CNC Routers for Advanced Machining.

Streamline Production Processes

Precision for Complex Designs

Advanced Innovation in CNC Machining

Full UK Warranty

Delivery Included

Installation Included

5 Axis Machining

Exceptional Service

Affordable 5 Axis CNC Router Machines - Exceptional Machining Capabilities

Features and Overview of the Apollo 5 Axis CNC Routers

5 Axis CNC Systems Built for Industrial Grade Performance

Side view

Rear View

Side View

Overview and Features

| Apollo 5 Axis CNC Datasheet | description |

|---|---|

| Table Sizes | Table sizes available: 1300 x 2500 mm / 1600 x 3100 mm / 2050 x 3050 mm / 2050 x 4000 mm |

| Spindle System | 6.0KW (upgrade options available) (12hp) ER32 air cooled spindle system 24,000rpm with automatic tool change function. 8 x ISO 30 tool holders/positions. |

| Max Z Height Travel | Max Z travel 465mm (without tooling/ material/ spoil board) |

| Mechanical Drive | Helical rack and pinion, reciprocating ball screw drives on Z. |

| Drive System | Yaskawa servo drive system – exceptional performance with lower power consumption |

| Control System | Syntec 5 axis/auto tool change control |

| Linear Guide Rails | HIWIN oil inject centralised linear rail lubrication. |

| Material Positioning Stops | Pneumatic pop-up end stops for material location |

| Vacuum Table Type | Yes - Multi-zone vacuum sytem allows for controlled vacuum areas across the bed, POD and Rail systems for side processing. |

| Tool Cooling System | Integrated pneumatic cutter cooling/lubrication system. |

| Extraction System | Yes included |

| Safety Features | Modular Safety fences with optical IR guarding. |

| Software Package Included | AlphaCam Standard Is required (or similar – ask for options). |

| Installation & Training | Our installation team carries out installation and safety training, giving you the confidence to use the machine before they leave. |

| Aftersales | After-sales service is UK based and available to all of our customers if needed. Lifetime technical support via email and telephone. |

| Warranty | All Apollo CNC Routers come with our leading 2 years parts & labour warranty (does not include consumables). |

Why Choose The Apollo 5 Axis CNC Router Range?

The Apollo 5 Axis CNC Router is the ultimate solution for businesses seeking versatility, precision, and innovation in machining. Engineered for industrial applications, it excels at handling complex geometries and intricate designs with unmatched accuracy and efficiency.

Equipped with high-speed servo motors, HSD 6kW spindles (with upgrade options), and an advanced CNC control system, the Apollo 5 Axis streamlines even the most demanding tasks. Seamless Fusion 360 CAD/CAM integration ensures a smooth transition from design to production, making it ideal for industries such as aerospace, automotive, and custom tooling.

With robust industrial construction, flexible tool storage options, and a T-slot material holding system, the Apollo 5 Axis guarantees stability and reliability for diverse applications. Backed by expert installation, training, and aftersales support, it’s the perfect choice for businesses looking to enhance their manufacturing capabilities.

Industries That Use the Apollo 5 Axis CNC Router

- Aerospace

- Mould and Die Making

- Custom Products

- Furniture and Woodworking

- Marine Engineering

- Automotive Engineering

- Pharmaceutical & Chemical

- Education

- Sculpture and Art

- Construction & More

Is Training and Delivery Included?

Yes, all of our CNC routers include standard delivery and full training. Our expert team will install your machine and provide in-depth training on both the hardware and software, ensuring you can confidently operate your CNC router from day one.

What About Aftersales Care?

At Mantech, we are committed to affordable machinery paired with first-class service. Our dedication to customer support extends from sales to aftercare, ensuring that every client receives the highest level of assistance.

We continuously invest in our team, procedures, and resources to maintain exceptional aftersales support. Additionally, we hold an extensive stock of parts and spares, allowing us to provide fast and reliable service whenever required.

| Wood | Plastics | Composites and other |

|---|---|---|

| Oak | Acrylic | ACM (like Alcubond, Dibond) |

| Birch wood | Polycarbonate | Foamex |

| MFC | Tufnol | Composite Fibreboard |

| Plywood | PVC | Solid Surface (Corian etc) |

| Walnut | Peek | Carbon Fibre |

| Pine | ABS | Graphite |

| Leather | HPDE | Tool Box Foam |

| Redwood | HPL | Laminated Woods |

| OSB board | Yes | Vermiculite Board |

| Cedar | Plexiglass | Trespa |

| Cherry | Nylon | Aluminium |

| Elm | Delrin | Brass |

Our CNC Routers are Great For

Request a Quick Quotation

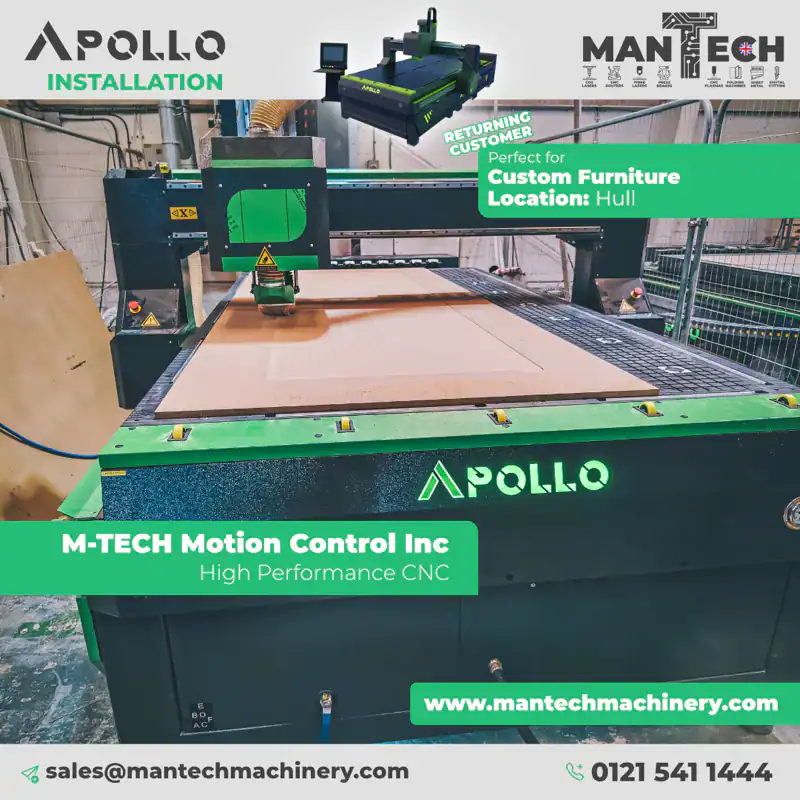

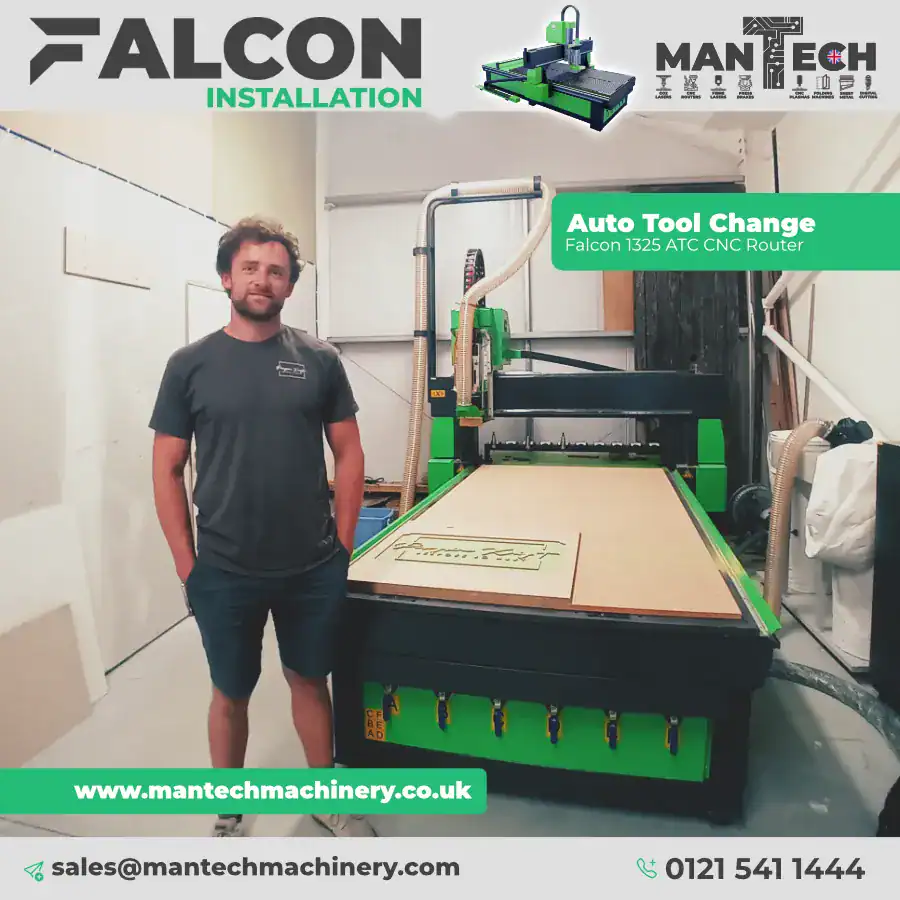

CNC Router Installations - Latest

Falcon 1300 x 2500 ATC CNC Router Installed in Chippenham

Falcon 1530 ATC CNC Router Installed for New Sign Maker in Leicester

Apollo 1313 ATC CNC Router Installed in Telford

Third Apollo ATC CNC Router Installed for Returning Customer

Falcon ATC CNC Router – New Customer Installation

CNC Routers for Upholstery and Furniture

Falcon ATC 1530 CNC Router Installed for Returning Customer in Dublin

Falcon 1325 ATC CNC Router Installed in Suffolk

Spartan 1313 CNC Router Installed at Belfast School

Falcon 1530 ATC CNC Router Installed in Newcastle

Falcon 1325 ATC Lands in Wadebridge