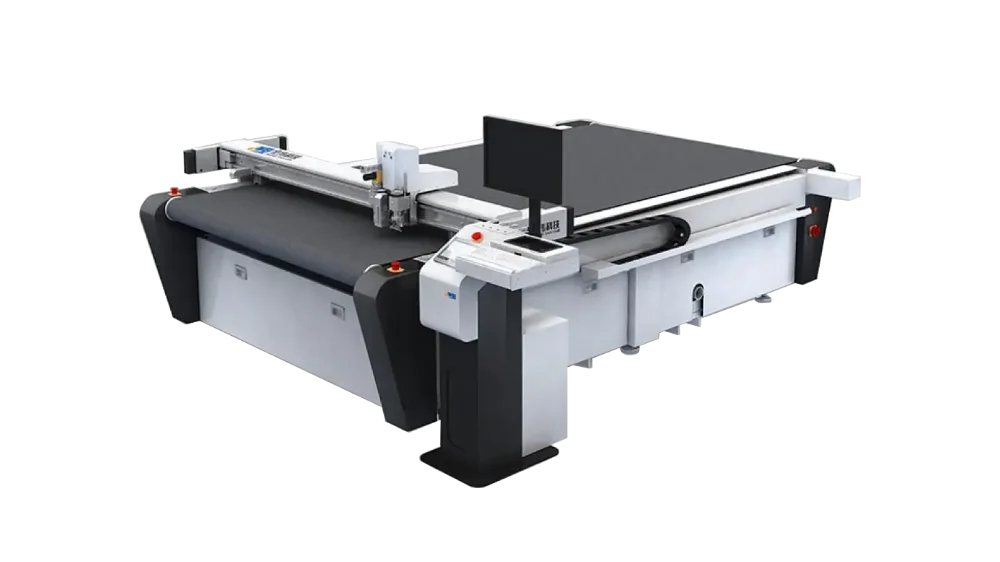

Digital Cutting Tables – High-Speed CNC Knife & Creasing Cutters

Versatile Cutting for a Wide Range of Materials

High-Speed Precision Cutting for Maximum Efficiency

Customisable Tooling for Enhanced Flexibility

Full UK Warranty

Delivery Included

Installation Included

Versatile Cutting System

Exceptional Service

Supplied with Full UK Delivery, Installation & Support

What is a Digital Cutting Table and how does it work?

A Digital Cutting Table (DCT) is an advanced, high-speed cutting machine designed to process a wide variety of materials with exceptional precision and efficiency. These machines can cut foam, rubber, plastic, paper, fabrics, cardboard, reboard, carbon fibre fabric, and more, making them a versatile solution for industries such as packaging, signage, textiles, and composites.

Unmatched Precision & Speed

DCT High-Speed Digital Cutting Machines are engineered for pinpoint accuracy and rapid operation, reaching speeds of up to 1,200 mm/s with a precision of 0.01 mm. This ensures clean, detailed cuts while reducing material waste and improving productivity.

How Does a Digital Cutting Table Work?

These cutting machines operate using a digital control system, which seamlessly integrates with CAD/CAM software. The process includes:

- Design Creation – The operator designs a cut file using CAD/CAM software.

- Data Transmission – The digital file is sent to the cutting table’s control system.

- Precision Cutting – A high-speed servo motor moves the cutting head, which is equipped with a high-precision cutting tool (such as an oscillating knife, creasing wheel, or router).

- Automated Execution – The machine executes the cut with unrivalled speed and accuracy, ensuring clean, precise edges every time.

Key Features of our Digital Cutting Table (DCT) systems

Our DCT systems can be configured with a variety of cutting tools, including:

- Oscillating knife tools for clean and precise cuts

- Creasing wheels for packaging and cardboard applications

- Optical recognition systems for enhanced accuracy

- Multi-angled V-cut tools for intricate designs

- Plotting pens & router engraving heads for added functionality

Maximise Efficiency with High-Speed Digital Cutting Technology

Why Choose a Digital Cutting Table?

Customer Case Study

Unicon

Business Type:

The Challenge:

The Solution:

The Result:

Versatile DCT Tooling Options Available

Oscillating Cutting Tool – Precision & Versatility

Available in Standard and Electric models, the Oscillating Cutting Tool is ideal for processing a wide range of materials with precision and efficiency. It is commonly used for cutting corrugated board, honeycomb board, fluted core (Correx), flexo plates, KT panels, Foamex, carpets, corrugated plastics, thin plastics (HIPS, PP sheets), gaskets, leather, and flexo glass, making it a versatile solution for diverse industries.

Optical Recognition System – Precision Cutting for Printed Materials

Our advanced Optical Recognition System ensures precise cutting of pre-printed substrates, such as UV-printed cardboard displays, signage, and packaging materials. The integrated camera scans registration marks and aligns them with the designated cut path in your file, guaranteeing high-accuracy contour cutting for perfectly finished projects.

Multi-Angled V-Cut Tool – Precision Folding & Shaping

Ideal for cutting honeycomb board, greyboard, and reboard, the Multi-Angled V-Cut Tool features an adjustable blade that allows for precise folding and bevel cutting. With cutting angles of 0°, 15°, 22.5°, 30°, and 45°, this tool enhances structural design capabilities, making it perfect for packaging, displays, and architectural modelling.

Rotary Engraving Head – Expand Your Cutting Capabilities

Upgrade your Digital Cutting Table with a router tool, allowing you to process a broader range of materials with precision. This versatile addition enables cutting and engraving on acrylic, Dibond/ACM board, MDF, epoxy panels, PVC board, PAL board, and wood, with cutting depths of up to 15mm, depending on the material. Perfect for signage, displays, and industrial applications.

Electric Rotary Tool – Precision Cutting for Textiles & Composites

Our Rotary tool is the perfect companion to process fabrics, carbon fibre/glass fibre, fur, grid cloth, textiles, banner/flag materials. This tool can process up to 8mm in thickness.

Creasing Wheel – Precision Scoring for Packaging & Display Materials

Plotting Pen – High-Precision Marking & Sketching

The plotting pen attachment is perfect for sketching/marking out designs onto materials with high accuracy and speed.

Kiss Cut Tool – Precision Cutting for Multi-Layered Materials

Perfect for processing thin multi-layered materials such as printed vinyl, vinyl, reflective vinyl and magnetic sheets (can also be pr-printed).

Perforation Tool – Precision Cutting for Tear-Away Designs

The Perforation Tool is perfect for creating tear-away sections on various materials. Ideal for applications such as tissue boxes, food packaging, and promotional displays, this tool enables easy-to-remove sections while maintaining material integrity, ensuring clean, controlled perforations for efficient packaging solutions.

DCT Technical Data Sheets

| DCT - BK Range | ||

|---|---|---|

| Multi-functional tool head | Oscillating cutting knife /Kiss cut/LED cursor location light | |

| Safety system | Infrared sensors to prevent unsafe operation | |

| Moving speed | Up-to 1200mm/s | |

| Cutting speed | Up-to 800mm/s | |

| Cutting thickness | Up-to 22mm (material dependant) | |

| Cutting table type | Static bed | |

| Vacuum Bed | Yes | |

| Repeat accuracy | ≤0.01mm | |

| Buffer memory | 2G | |

| Transmission system | Digital servo driver, straight rail synchronous belt | |

| Command system | HP-GL compatible format | |

| Power Supply | 380V±10% 3 Phase 32 amp supply on Machine Rated ‘D’ Breaker | |

| BK Range Cutting Area | BK03II-1816 | BK03II-2516RM |

| Cutting area options | 1800mm*1600mm | 2500mm*1600mm |

| DCT - CB03II Range | |

|---|---|

| Multi-functional tool head | Oscillating cutting knife /Kiss cut/LED cursor location light, engraving/router (optional), creasing wheel, camera recognition (optional) |

| Safety system | Infrared sensors to prevent unsafe operation |

| Moving speed | Up-to 1500mm/s |

| Cutting speed | Up to 1200mm/s |

| Cutting thickness | Up to 50mm (material dependent) |

| Cutting table type | Auto feed bed system |

| Vacuum Bed | Yes |

| Repeat accuracy | ≤0.01mm |

| Buffer memory | 2G |

| Transmission system | Digital servo driver, straight rail, synchronous belt, guide screw |

| Command system | HP-GL compatible format |

| Power Supply | 380V±10% 3 Phase 32 amp supply on Machine Rated ‘D’ Breaker |

| CB03II-2513RM | 2500mm*1300mm |

| CB03II-2516RM | 2500mm*1600mm |

| CB03II-1113 | 1100mm*1300mm |

| CB03II-1816RM | 1800mm*1600mm |

| DCT - CB08II Range | |

|---|---|

| Multi-functional tool head | Oscillating cutting knife /Kiss cut/LED cursor location light, engraving/router (optional), creasing wheel, camera recognition (optional) |

| Safety system | Infrared sensors to prevent unsafe operation |

| Moving speed | Up-to 1500mm/s |

| Cutting speed | Up-to 1200mm/s |

| Cutting thickness | Up to 50mm (material dependent) |

| Cutting table type | Auto feed bed system |

| Vacuum Bed | Yes |

| Repeat accuracy | ≤0.01mm |

| Buffer memory | 2G |

| Transmission system | Digital servo driver, straight rail, synchronous belt, guide screw |

| Command system | HP-GL compatible format |

| Power Supply | 380V±10% 3 Phase 32 amp supply on Machine Rated ‘D’ Breaker |

| CB08II-2516PM | 2500mm*1600mm |

| CB08II-3516PM | 3500mm*1600mm |

| CB08II-5516PM | 5500mm*1600mm |

| CB08II-2520PM | 2500mm*2000mm |

| CB08II-3520PM | 3500mm*2000mm |

| CB08II-5520PM | 5500mm*2000mm |

| CB08II-3032PM | 3000mm*3200mm |