Yes, we offer extended warranties on all of our Fibre Laser Cutters for up to 5 years, providing additional peace of mind and long-term protection for your investment.

Fibre Laser Cutters - Precision Metal Cutting Solutions

For businesses demanding unparalleled precision, speed, and versatility in metal cutting, fibre laser cutters represent the pinnacle of modern technology. At Mantech Machinery UK, we supply a comprehensive range of high-performance fibre laser cutting machines designed to elevate your manufacturing capabilities. From intricate designs to high-volume production, our industrial fibre laser cutters deliver exceptional results across diverse materials and applications... Read more about Fibre Laser Safety

Reliable Delivery Service

Standard UK delivery is included, with HIAB options available upon request. Transparent upgrade options ensure a smooth and hassle-free experience.

Expert Installation Service

Our skilled Fibre Laser Engineering team will commission your machine, ensuring optimal performance. Ongoing support is available whenever you need assistance.

Intuitive Software Package

Our fibre laser cutters come with Cypcut or CypTube for SF models and V-CUT for Vector FL models, ensuring seamless operation, drawing, nesting, and processing.

Comprehensive Training

We provide in-depth operator training to ensure safe and efficient machine use. Additional training sessions can be arranged as needed for ongoing skill development.

Advanced Extraction System

Our Cyclone Extraction System is available for all models, ensuring compliance with health and safety standards while providing powerful and efficient fume extraction.

Comprehensive UK Warranty

Every machine comes with a 2-year standard warranty, with options to extend coverage through additional service plans for long-term peace of mind.

Fibre Laser Cutter Models Offered by Mantech Machinery.

Mantech Machinery UK offers a curated selection of high-quality fibre laser cutting machines to suit diverse business needs and budgets. Browse our range belowExplore our range below and discover how Mantech Machinery can provide the perfect fibre laser cutting solution to meet your specific needs.

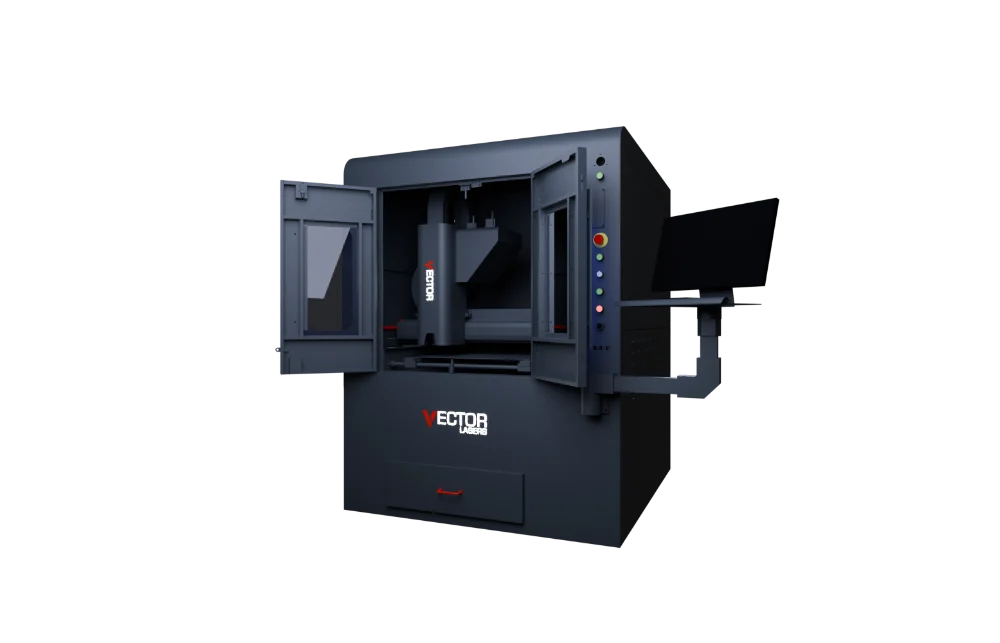

Vector FL60 Fibre Laser

The Vector FL60 Fibre Laser features an ultra-compact 600 x 600 mm worktable, making it the perfect solution for precision cutting in limited spaces. Designed for efficiency and affordability, this high-performance system delivers powerful cutting capabilities while maintaining a small footprint, ideal for workshops and businesses requiring cost-effective precision machining.

Vector FL60 Fibre Laser – Compact, Powerful & Affordable Precision Cutting

Vector FL90 Fibre Laser

The FL90 Fibre Laser is one of our most popular models, offering a compact yet powerful design with a spacious 1300 x 900 mm cutting table. With cutting capabilities of up to 3kW, this versatile system is ideal for businesses seeking precision, efficiency, and reliability in a space-saving footprint.

Vector FL90 Fibre Laser – Compact, Powerful & Versatile Cutting Solution

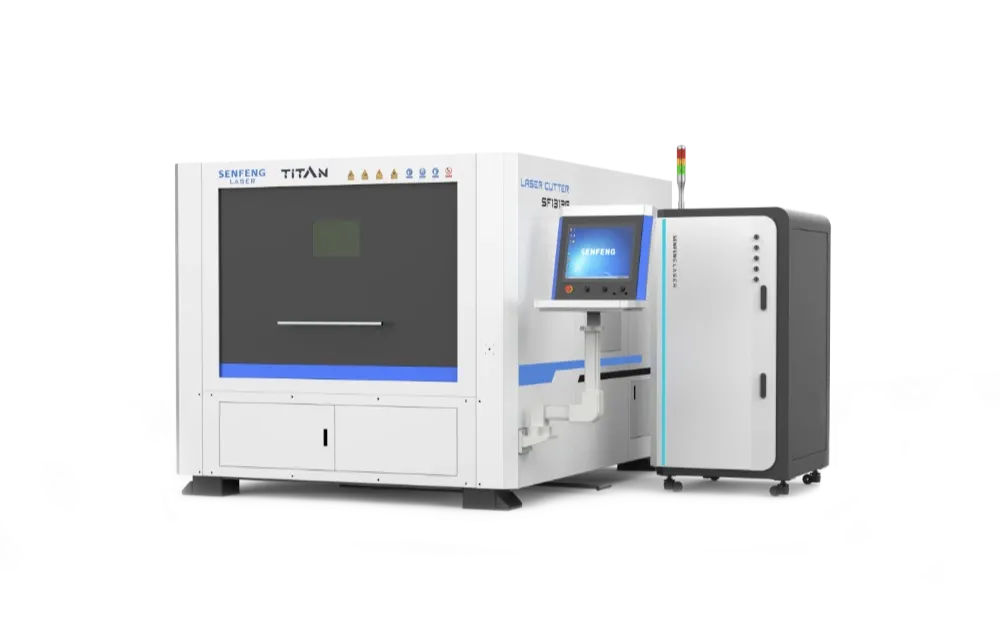

Vector FL130 Fibre Laser

Building on the proven performance of the FL90, the FL130 Fibre Laser offers an expanded 1300 x 1300 mm cutting table, providing greater flexibility while maintaining a compact footprint. Ideal for businesses requiring enhanced versatility, the FL130 delivers precision, efficiency, and reliability in a space-conscious design.

Vector FL130 Fibre Laser – Expanded Cutting Area with Compact Versatility

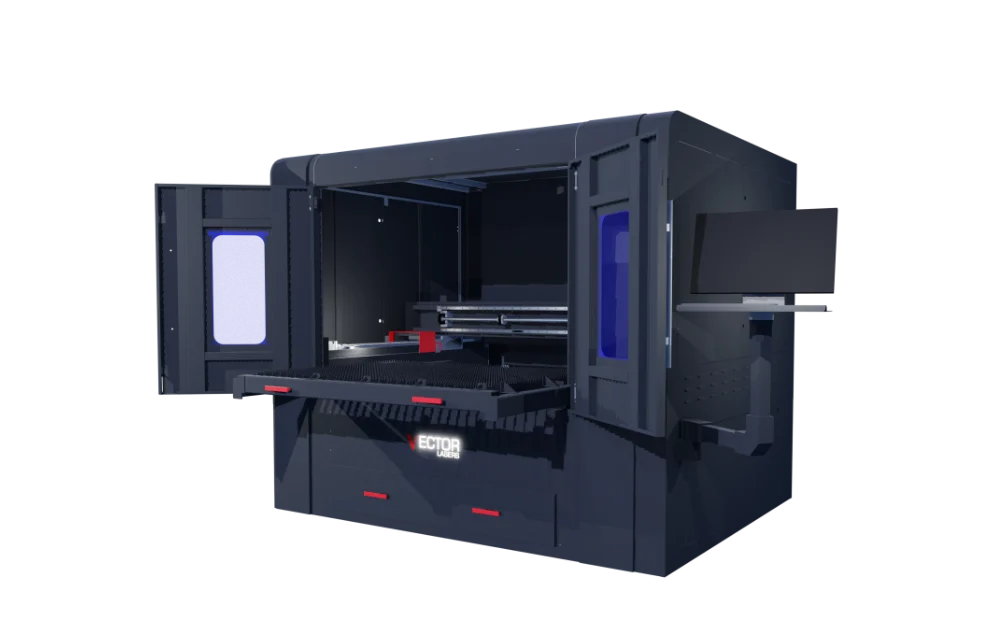

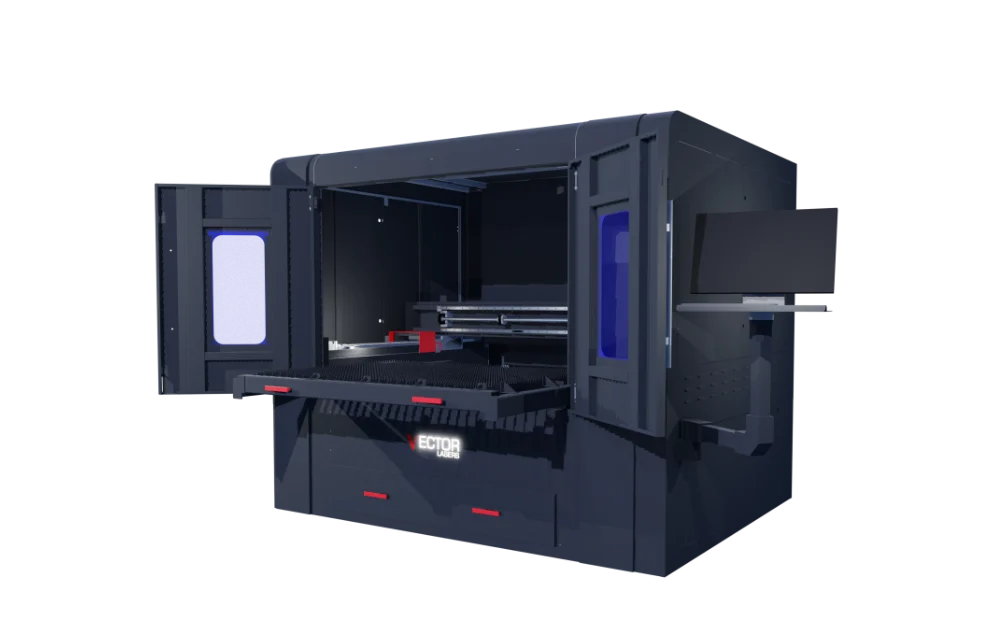

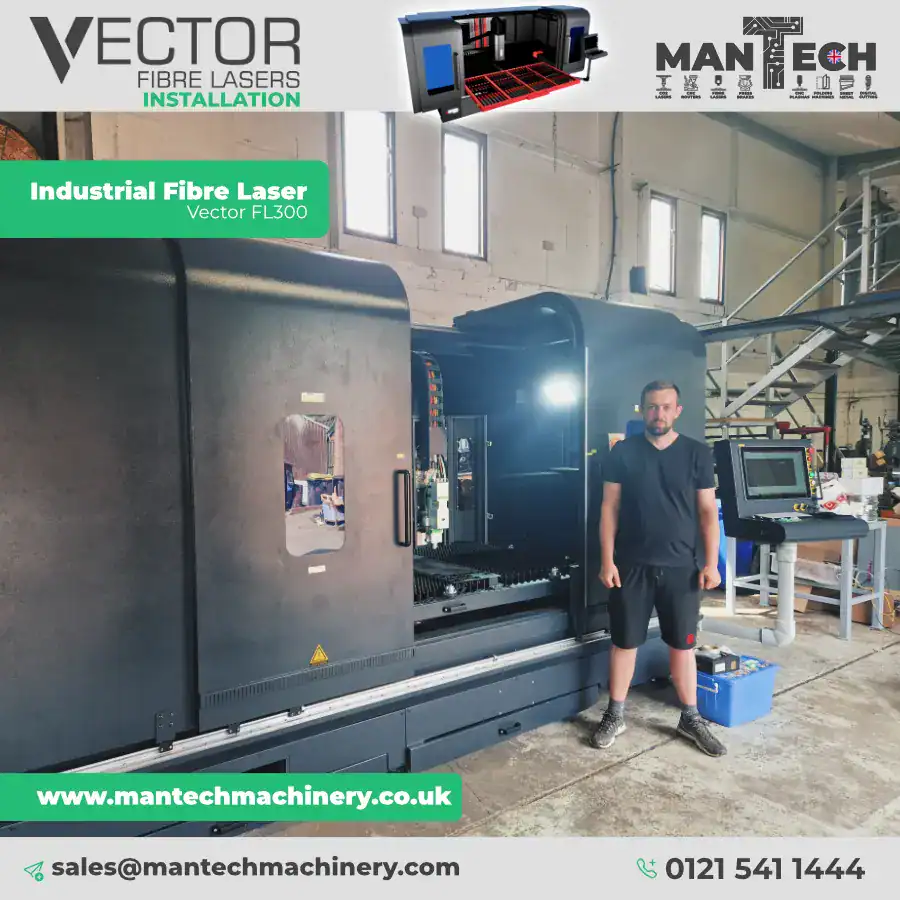

Vector FL250/300 Range

The ideal choice for businesses needing larger cutting areas and increased power, the FL250 and FL300 models provide enhanced versatility and precision. Available in 1260 x 2510 mm (FL250) and 1500 x 3000 mm (FL300 Plus), these fibre lasers deliver exceptional cutting performance for industrial applications requiring high efficiency and reliability.

Vector FL250 & FL300 – Larger Cutting Tables for High-Power Performance

SF Medium Powered Fibre Laser Cutters

Our mid-range SF C Gen Fibre Laser Cutter provides a configurable power range from 1.5kW to 6kW, allowing businesses to tailor the system to their cutting needs. Fully enclosed for enhanced safety and fume extraction, this highly popular model offers exceptional performance at a competitive price, making it the ideal solution for precision metal cutting.

SF C Gen Fibre Laser Cutter – Versatile, Enclosed & Configurable Power Options

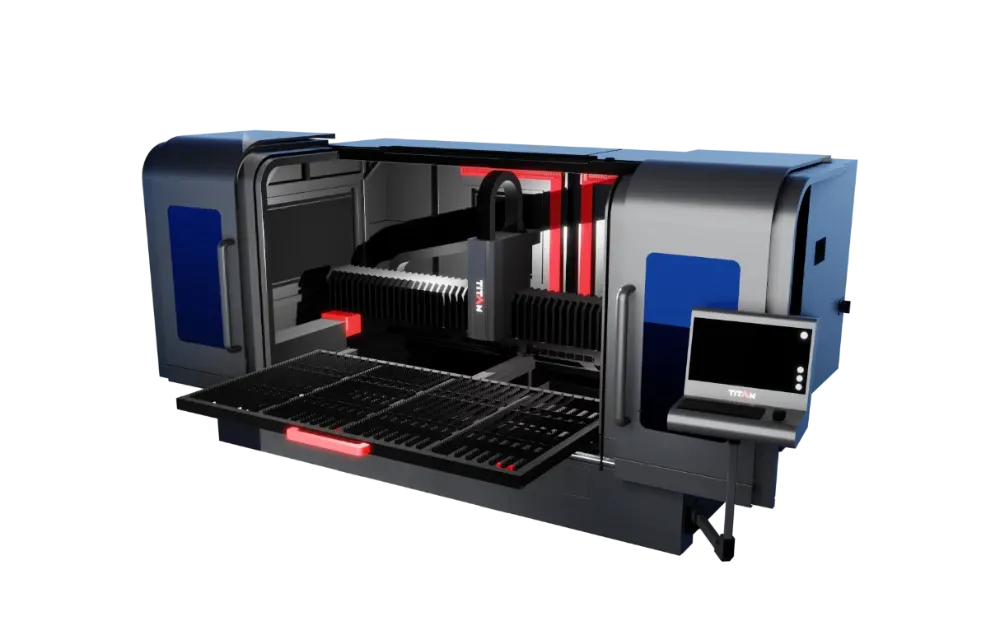

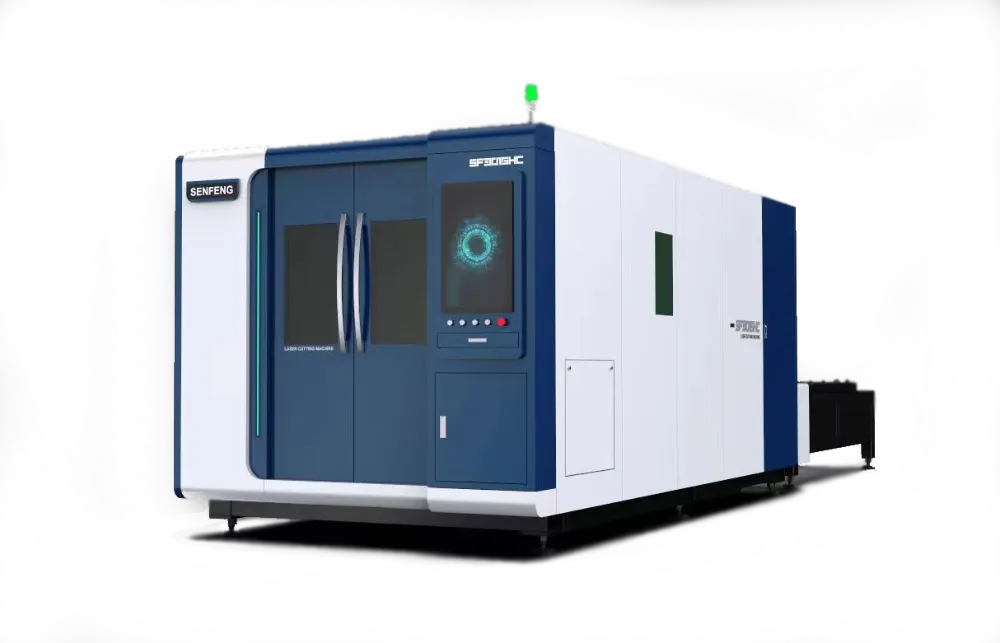

SF High Powered Fibre Laser Cutters

Our 4th Generation High-Power Fibre Laser Cutters offer configurable laser power options ranging from 6kW to 30kW, delivering exceptional cutting speed and precision. Featuring auto-exchange shuttle tables for continuous workflow, these systems provide high-performance metal cutting for demanding industrial applications.

4th Gen High-Power Fibre Laser Cutters – Advanced Performance & Efficiency

SF Ultra High Powered Fibre Laser Cutters

Our 5th Generation Ultra-High Power Fibre Laser Cutters deliver unmatched industrial cutting capabilities, with power options up to 60kW and processing lengths of up to 12.1 metres. Designed for high-volume production, this powerhouse features an auto-exchange shuttle table, ensuring continuous operation, precision, and ultimate versatility for demanding applications.

5th Gen Ultra-High Power Fibre Laser Cutters – Up to 60kW for Maximum Performance

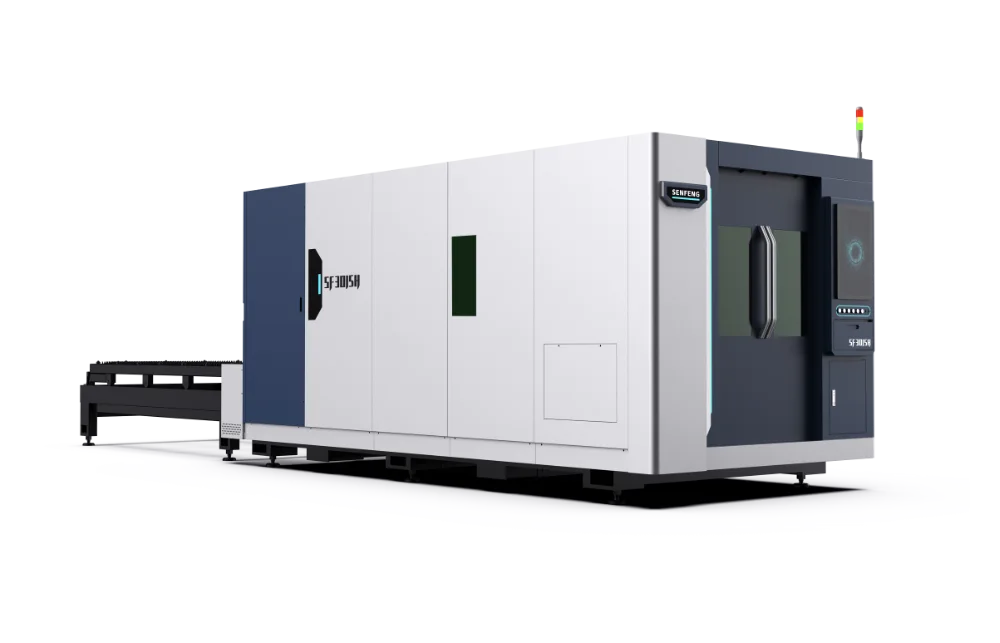

SF Bevel Cut Fibre Laser Cutters

Harness the power of the SF3015H, featuring 0-45° bevel cutting capabilities for enhanced precision on the cutting plane. This fully enclosed system ensures safety and efficiency, while the shuttle exchange table streamlines workflow, making it an ideal choice for high-performance sheet metal cutting applications.

SF3015H Fibre Laser – Precision 0-45° Bevel Cutting with Enclosed Efficiency

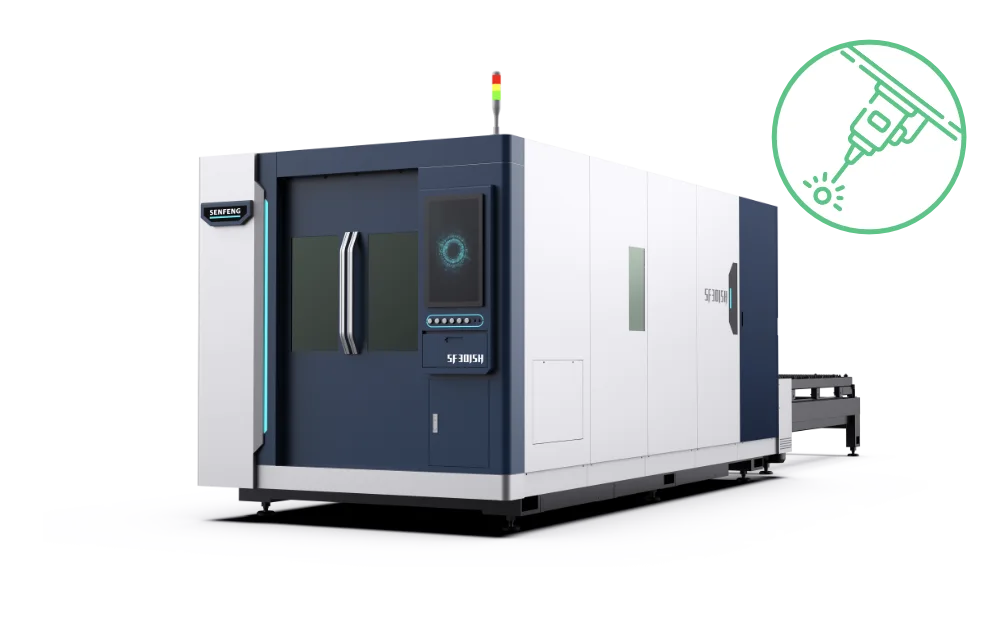

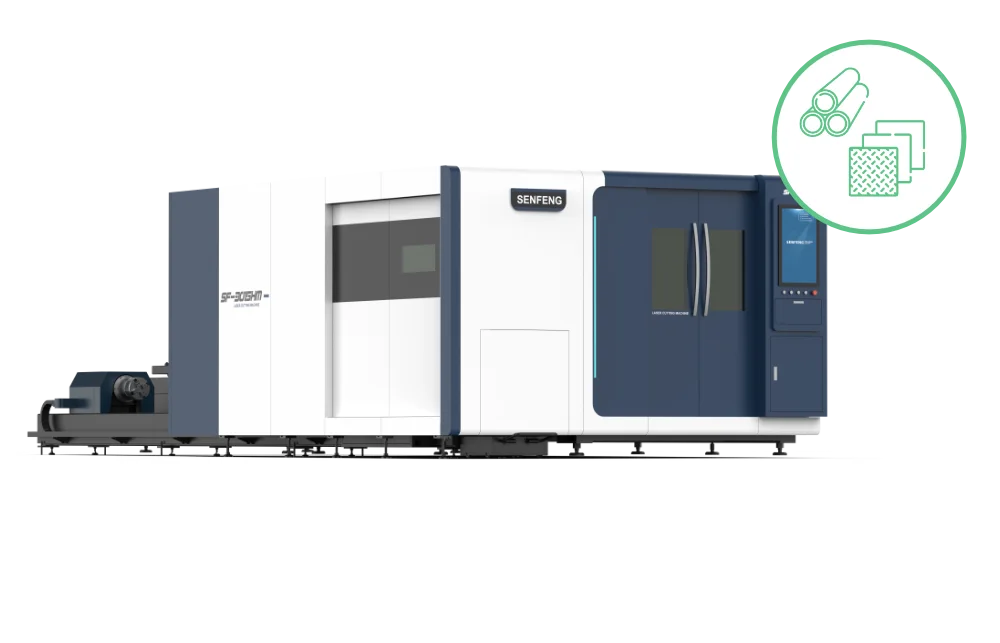

SF Combination Fibre Laser Cutters

Unlock the versatility of the SF3015HM, featuring integrated tube cutting capabilities alongside flatbed operation. This space-saving solution is perfect for businesses needing both sheet and tube cutting without requiring a separate machine, offering efficiency, precision, and seamless workflow integration.

SF3015HM Fibre Laser – Dual-Purpose Flatbed & Tube Cutting Solution

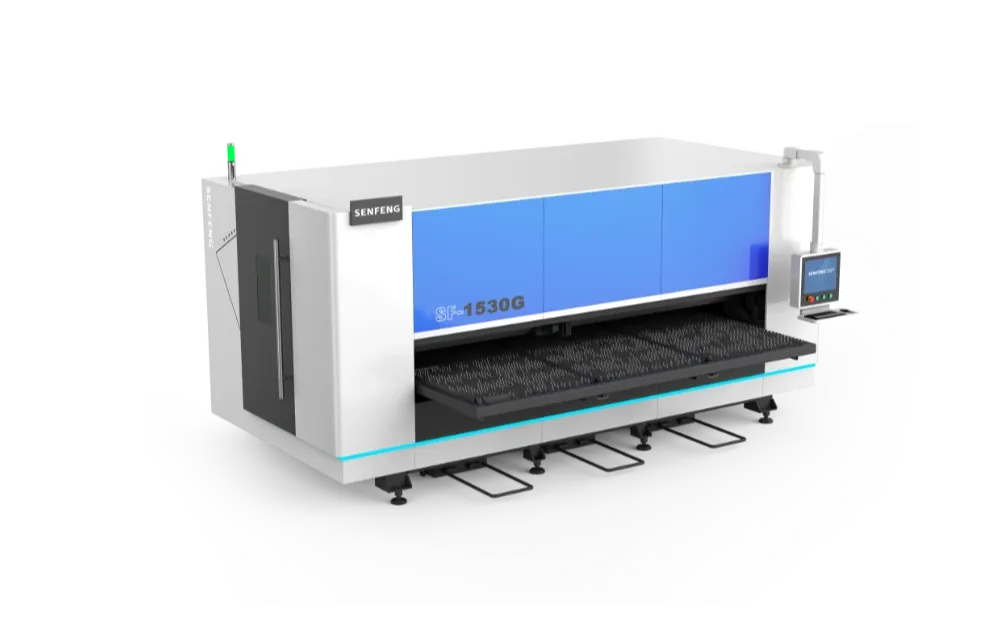

SF Single Table Fibre Laser Cutters

The SF1530G range is ideal for businesses that don’t require dual shuttle exchange tables, reducing floor space requirements while maintaining cutting efficiency. With a 1530 x 3050 mm bed and power options from 1kW to 3kW, this versatile system delivers precision and reliability for a wide range of cutting applications.

SF1530G Fibre Laser – Space-Saving, High-Precision Cutting Solution

SF Compact Fibre Laser Cutters

Save space without compromising on cutting capability with the SF1313G series. Featuring 1.5kW to 3kW power options and a 1300 x 1300 mm cutting bed, this model is the perfect choice for smaller workshops needing precision, efficiency, and versatility in a compact footprint.

SF1313G Fibre Laser – Compact Design, Powerful Performance

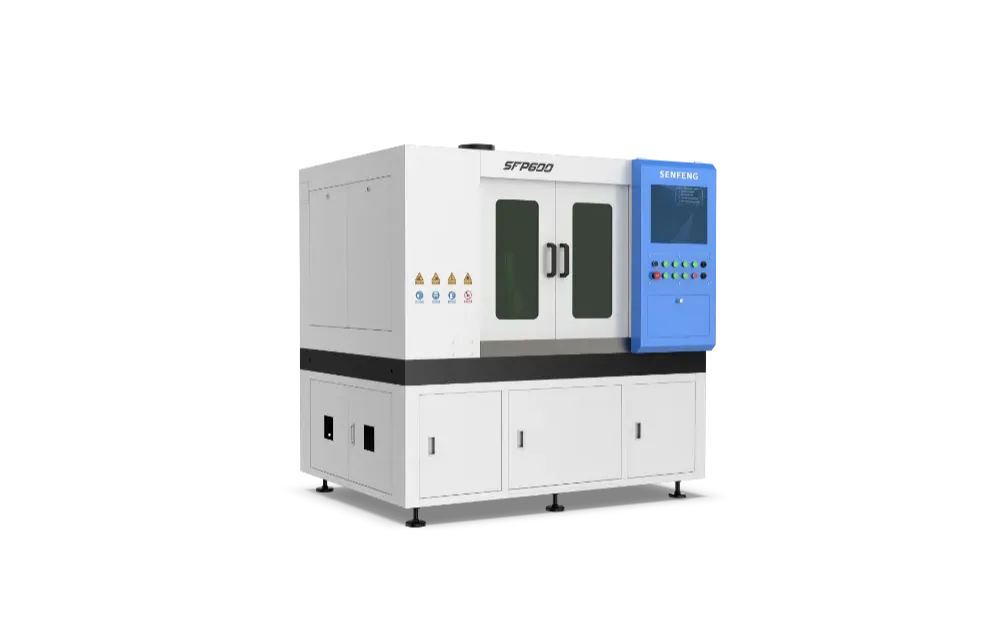

SF Ultra Compact Fibre Laser Cutters

Our smallest Fibre Laser Cutter, the SF6060, is designed for precision cutting of thin metal sheets ranging from 0.2mm to 5mm. Featuring a 600 x 600 mm cutting bed and power options from 1.5kW to 3kW, this ultra-compact system delivers high accuracy and efficiency, making it ideal for small-scale metal cutting applications.

Ultra-Compact SF6060 Fibre Laser – Precision Cutting for Thin Metals

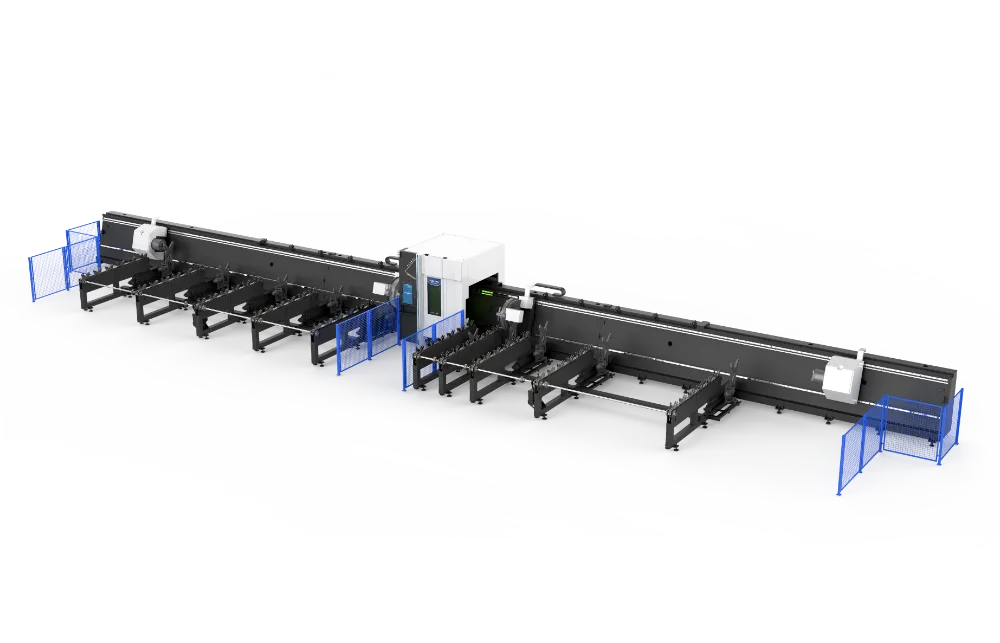

SF Ultra Heavy X4 Chuck Tube Fibre Laser Cutters

The SF12050HT is engineered for ultra-heavy tube and profile cutting, featuring a vertically mounted rail system for enhanced stability and precision. With laser power options from 4kW to 12kW, it can process round tubes from 50mm to 500mm in diameter, making it the ideal solution for large-scale industrial applications.

SF12050HT Ultra Heavy-Duty Tube Laser – Precision Cutting for Large Profiles

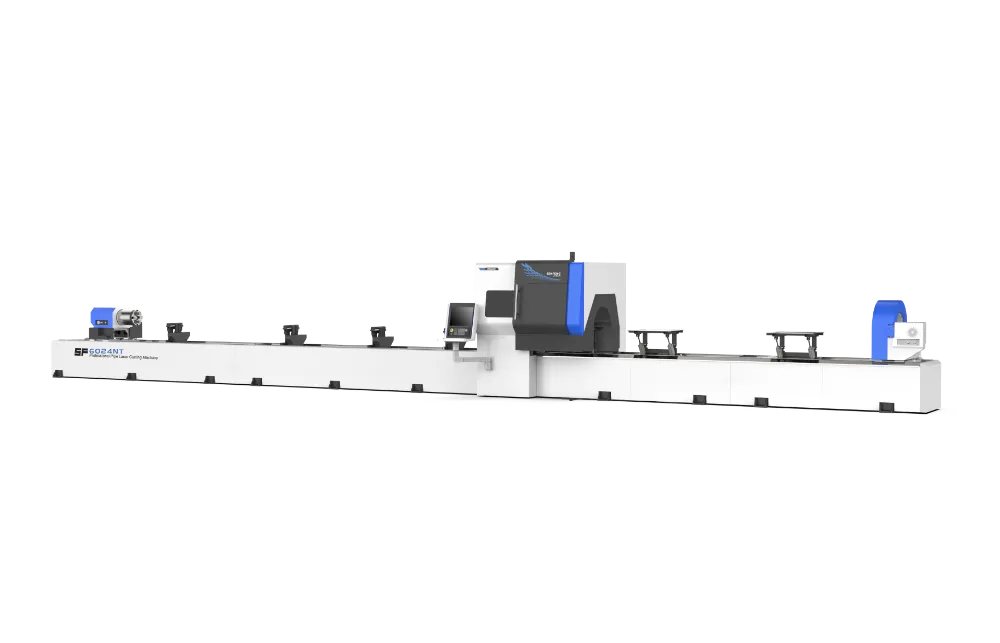

SF X3 Chuck Tube Fibre Laser Cutters

Designed for larger material lengths, this 3-chuck system is available in 6m and 12m models, supporting 240mm and 350mm diameters. Capable of cutting round, square, rectangular, L, U, and H-shaped profiles, it ensures maximum material utilisation with zero tailing, making it a high-efficiency solution for industrial tube processing.

Advanced 3-Chuck Tube Laser – High-Capacity, Zero Tailing Cutting

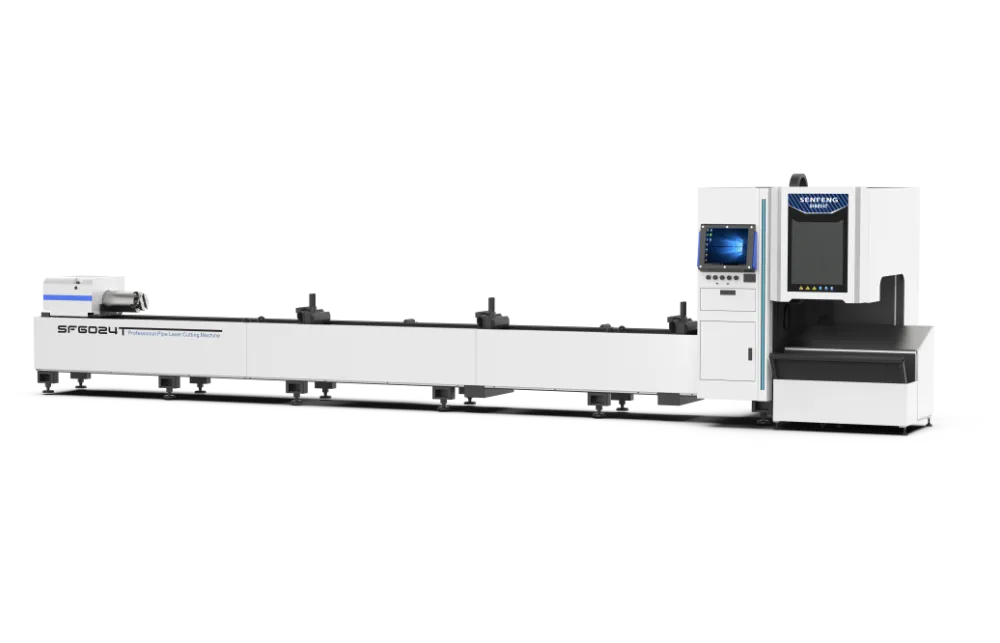

SF X2 Chuck 6m Tube Fibre Laser Cutters

With an outer diameter capacity of up to 220mm and a maximum processing length of 6m, the SF6000 range is ideal for various industrial applications. For enhanced automation, it can be configured with auto-load and unload options, offering increased efficiency and versatility in tube and profile cutting.

SF6000 Tube Laser – Versatile & High-Capacity Cutting Solution

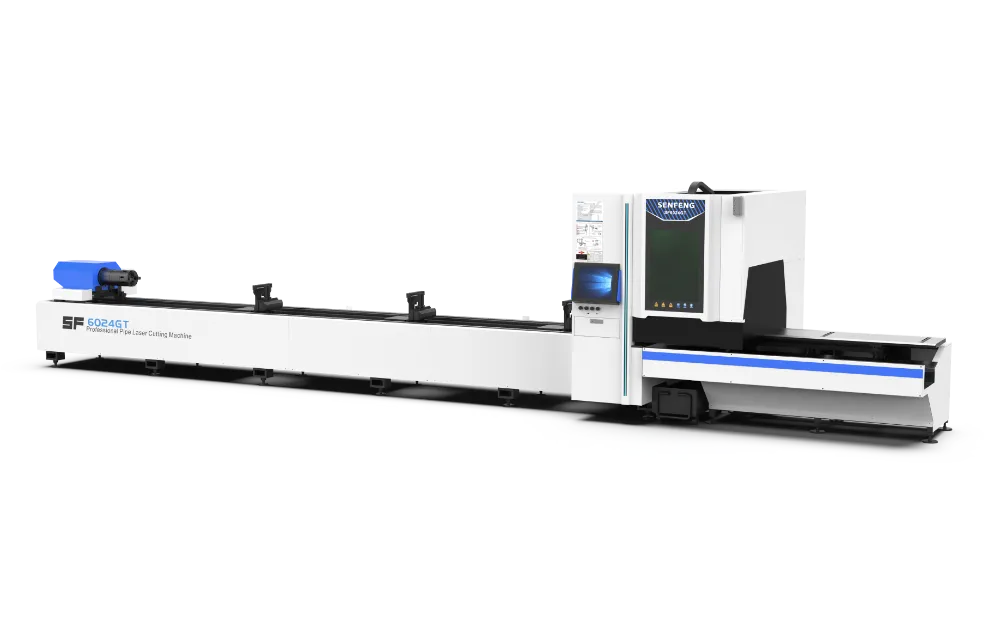

SF Bevel Cut Tube Fibre Laser Cutters

Our tube lasers feature powerful 45° bevel cutting capabilities, expanding production versatility and precision. Available with laser power sources ranging from 3kW to 6kW, this system ensures high-quality cuts and improved processing efficiency for a wide range of tube and profile applications.

Advanced 45° Bevel Cutting – Enhanced Tube Laser Performance

Why Choose Us For Fibre Laser Cutters?

At Mantech, we provide high-performance fibre laser cutting solutions backed by industry expertise, exceptional service, and cutting-edge technology. Our commitment to quality, precision, and reliability ensures that your business benefits from the best metal-cutting technology available.

Competitive pricing

Our fibre laser range is affordably priced, offering businesses a cost-effective route to precision manufacturing. Finance options available.

Delivery included

Standard delivery is included with all fibre laser purchases. While offloading and siting are the customer’s responsibility, we provide guidance.

Training included

Every fibre laser cutter comes with comprehensive operator training, ensuring your team can operate the machine safely and efficiently.

UK engineering and support teams

Our dedicated engineering and support teams are 100% UK-based at our HQ in Halesowen, West Midlands and provide fast response times and expert technical assistance.

Software included

All machines come with specialist software, featuring nesting, fly-cutting, and edge-seek detection for optimised cutting and efficiency.

Installation included

All machines come with specialist software featuring nesting, fly-cutting, and edge-seek detection for optimised cutting and efficiency.

Exceptional aftercare

Our fully staffed service desk, with a dedicated team of five support specialists and nearly 20 experienced engineers, ensures exceptional aftercare for our customers, providing fast, reliable technical assistance and maintenance.

A quarter of a Century in Business

With 25 years under our belt, we have the people and resources to ensure you get the best of the best.

Understanding Fibre Laser Cutting Technology

How Fibre Laser Cutters Work: A Simple Explanation

Fibre laser cutting technology harnesses the power of light to achieve incredibly precise and rapid metal cutting. Unlike traditional methods, fibre lasers generate a focused beam of light within an optical fibre. This light is then amplified and directed through a cutting head, concentrating immense energy onto a tiny focal point on the material surface

This intense laser energy instantly vaporises, melts, or burns away the material, creating a clean and accurate cut. The process is controlled by sophisticated CNC (Computer Numerical Control) systems, allowing for intricate shapes and patterns to be produced with exceptional repeatability.

Key Components of a Fibre Laser Cutter

- Fiber Laser Source: The heart of the system, generating the high-powered laser beam. Different power levels are available depending on cutting requirements and material thickness.

- CNC Control System: The “brain” of the machine, guiding the cutting head with precision based on programmed designs. Advanced CNC systems offer user-friendly interfaces and sophisticated features for optimal control.

- Cutting Head: Focuses the laser beam onto the material and often incorporates sensors and automated features to maintain optimal cutting distance and quality.

- Beam Delivery System: Optical fibres that efficiently transmit the laser beam from the source to the cutting head.

- Motion System (X, Y, Z Axes): Allows the cutting head to move precisely across the material in three dimensions, following the programmed cutting path.

- Chiller Unit: Essential for maintaining the optimal operating temperature of the laser source and other critical components, ensuring consistent performance and longevity.

- Extraction System: Removes fumes and particulate matter generated during the cutting process, ensuring a safe and clean working environment.

Advantages of Fibre Laser Technology vs. Traditional Methods

Choosing fibre laser cutting machines offers significant advantages over older metal cutting technologies like plasma cutting, CO2 lasers, and mechanical methods. For businesses seeking to optimize their operations and gain a competitive edge, the benefits are compelling:

- Unmatched Precision: Fiber lasers deliver exceptionally clean and accurate cuts, with tight tolerances and minimal heat-affected zones. This reduces the need for secondary finishing processes and improves part quality.

- Faster Cutting Speeds: Compared to CO2 lasers and plasma, fibre laser cutters can achieve significantly faster cutting speeds, particularly on thinner gauge materials. This translates to increased throughput and reduced production time.

- Versatility in Materials: Fiber lasers are highly effective on a wide range of metals, including steel, stainless steel, aluminium, copper, brass, and more. They can handle reflective materials more efficiently than CO2 lasers.

- Lower Operating Costs: Fiber lasers are more energy-efficient than CO2 lasers, leading to reduced electricity consumption. They also typically require less maintenance and have longer lifespans, further lowering running costs.

- Minimal Material Waste: The precision and narrow kerf (cut width) of fibre lasers minimise material waste, leading to cost savings, especially when working with expensive metals.

- Automation Potential: Industrial fibre laser cutters are easily integrated with automation systems, enabling lights-out manufacturing and increased productivity.

Applications of Fibre Laser Cutters Across Industries

The versatility and precision of fibre laser cutting machines make them indispensable across a wide spectrum of industries. From heavy manufacturing to delicate component fabrication, fibre lasers provide solutions for diverse applications:

Metal Fabrication

Fibre laser cutters are foundational tools in metal fabrication workshops. They are used to create a vast array of components and structures, including:

- Structural steel components for buildings and infrastructure

- Machine frames and enclosures

- Sheet metal parts for industrial equipment

- Custom brackets, plates, and profiles

- Architectural metalwork and decorative elements

Automotive Industry

The automotive sector relies heavily on fibre laser cutting for high-volume, high-precision production of:

- Chassis and body panels

- Exhaust systems

- Interior components

- Engine and transmission parts

- Custom automotive accessories

Aerospace Industry

In aerospace, where material integrity and accuracy are paramount, fibre lasers excel in cutting critical components from advanced alloys:

- Aircraft structural parts

- Engine components

- Interior panels and fixtures

- Satellite and space vehicle components

Signage and Display

Fibre laser cutters enable the creation of intricate and eye-catching signage and displays from various metals:

- Corporate logos and branding elements

- Retail signage and promotional displays

- Wayfinding systems

- Decorative metal art and sculptures

Electronics Industry

The precision of fibre lasers is crucial for the electronics industry in manufacturing:

- Circuit board stencils

- Precision enclosures and housings

- Heat sinks and cooling components

- Connectors and terminals

Why Choose Mantech’s Fibre Laser Cutting Machines?

✔ Competitive Pricing – High-performance fibre lasers at an affordable cost.

✔ Expert Installation – Nationwide installation by highly experienced engineers.

✔ Versatile Applications – Ideal for engineering, fabrication, signage, and more.

✔ Precision & Control – Windows PC-based system with a wireless pendant controller.

✔ Compact & Industrial Solutions – Options available for businesses of all sizes.

Bringing Fibre Laser Cutting In-House

With affordable fibre laser technology, businesses can now take control of their productivity and quality assurance. Advancements in manufacturing have reduced costs, making state-of-the-art fibre lasers accessible to small engineering and fabrication firms.

Looking to cut costs and increase efficiency? Now is the perfect time to invest in a Mantech Fibre Laser Cutter and take your metal cutting process to the next level.

What Can You Cut With a Fibre Laser Cutting Machine?

Mild Steel

All of our Fibre Laser Cutters can cut mild/carbon steel, with cutting thickness dependent on the laser power source you choose.

Stainless Steel

Achieve high-accuracy stainless steel cutting with our Vector or Senfeng laser cutters, delivering clean and precise results.

Aluminium

Aluminium* can be processed on a fibre laser cutter with the correct settings. Our team can advise on the best cutting solution for this reflective metal.

Titanium

Cut titanium plates efficiently using our range of Fibre Lasers, optimising performance with the correct assistive gases and parameters.

Brass

Brass has high reflectivity and requires a specialist reflective absorption protective device* to be safely and effectively processed on a Fibre Laser.

Copper

Copper, like brass, has high reflectivity and requires a reflective absorption protective device within the cutting head for safe and precise cutting.

Choosing the Right Fibre Laser Cutter for Your Business - A Buyer's Guide

Investing in a fibre laser cutter is a significant decision. To ensure you select the optimal machine for your specific needs and maximise your return on investment, consider these key factors:

Key Factors to Consider before Purchasing

Material Thickness & Type

What materials will you be cutting most frequently? Steel, stainless steel, aluminium, or a mix? What are the maximum thicknesses you need to process? Fibre laser cutters are excellent for a wide range of materials, but understanding your primary materials is crucial for selecting the right power level.

Laser Power

Laser power directly impacts cutting speed and the maximum thickness you can cut. Higher power lasers offer faster cutting and greater material penetration but also come with a higher investment. Mantech Machinery's experts can advise on the appropriate power level for your applications.

Work Area/Bed Size

Consider the dimensions of the typical workpieces you'll be processing. Choose a machine with a work area that comfortably accommodates your material sizes.

Floor Space and Workshop Environment

Assess your available workshop floor space and the suitability of your environment. Consider the machine's footprint, required clearances for operation and maintenance, ventilation needs for fume extraction, and floor loading capacity to ensure your facility can properly accommodate the chosen fibre laser cutter.

Automation Features

For high-volume production, explore automatic fibre laser cutters with features like automated loading and unloading systems, part removal mechanisms, and advanced nesting software. These features can significantly boost productivity and reduce manual labour.

CNC Control System & Software

Opt for a user-friendly CNC control system with intuitive software that is compatible with your existing CAD/CAM software. Look for features that simplify programming and optimise cutting paths.

Budget and ROI

Establish a clear budget and consider the long-term return on investment. Factor in not just the initial machine cost but also operating expenses, maintenance, and potential productivity gains. Contact Mantech Machinery to discuss financing options and potential ROI calculations.

Scalability and Future Needs

Think long-term. Consider your potential future growth and production demands. Will the selected fibre laser cutter be able to scale with your business? Are there options for future upgrades or modular additions to increase capacity if needed? Choosing a scalable solution can be a smart long-term investment.

After-Sales Support & Maintenance

Reliable after-sales support is essential. Ensure your supplier offers comprehensive training, readily available technical support, spare parts, and preventative maintenance programmes. Mantech Machinery prides itself on providing exceptional customer support and service throughout the lifecycle of your machine.

Mantech Machinery – Your Trusted Partner for Fibre Laser Cutting Solutions

Decades of Expertise in Machinery Supply

For over 25 years, Mantech Machinery UK has been a leading supplier of high-quality industrial machinery to businesses across the UK and beyond. Our deep-rooted experience in the machinery sector means we understand the critical demands of modern manufacturing and are committed to providing solutions that drive efficiency, productivity, and profitability. We have a proven track record of partnering with businesses of all sizes, from small workshops to large-scale industrial operations, providing tailored machinery solutions and expert support.

Uncompromising Quality and Reliable Performance

We understand that machine downtime can be costly. That’s why Mantech Machinery sources only fibre laser cutters from reputable manufacturers known for their robust engineering and reliable performance. We rigorously evaluate each machine to ensure it meets our stringent quality standards before offering it to our customers. Our commitment to quality means you can rely on your Mantech fibre laser cutting machine to deliver consistent, high-performance results day in and day out.

Comprehensive Support and After-Sales Service

Our commitment to you extends far beyond the initial machine purchase. Mantech Machinery provides a comprehensive suite of after-sales services to ensure your continued success. This includes:

- Professional Installation and Commissioning: Our experienced engineers will ensure your fibre laser cutter is installed correctly and commissioned for optimal performance.

- In-depth Training: We provide thorough training to your operators, ensuring they can effectively and safely operate your new machine and maximise its capabilities.

- Ongoing Technical Support: Our dedicated technical support team is readily available to answer your questions, troubleshoot issues, and provide expert guidance.

- Spare Parts Availability: We maintain a stock of commonly needed spare parts to minimise downtime and ensure rapid repairs when necessary.

- Preventative Maintenance Programmes: We offer customisable preventative maintenance programmes to keep your machine running smoothly and extend its lifespan.

At Mantech Machinery, we are your partners in productivity. We are dedicated to providing not just exceptional machinery, but also the ongoing support you need to thrive.

Advanced Fibre Laser Software Features

Every fibre laser cutter comes equipped with powerful software and cutting-edge features, ensuring seamless production from day one. Designed for efficiency and ease of use, our software includes a range of essential tools to optimise your workflow and maximise productivity.*

Comprehensive Software

Package

Seamless System

Integration

Advanced

Feature Set

User-Friendly Operation

Intuitive controls make machine operation simple, with advanced features available for experienced users.

Material Optimisation (Nesting)

Maximises material usage by optimising part placement, reducing waste, lowering costs, and improving efficiency.

Smart Parts Library

Easily modify standard components by adjusting hole size, length, and width for quick customisation.

Precision Cutting Compensation

Adjusts the cutting path to account for kerf width, ensuring high accuracy and consistency.

Integrated Engraving

Includes a built-in engraving function for marking bend lines, part numbers, or custom details.

Efficient Edge Cutting (Common)

Reduces cutting time and material waste by using shared cut lines for multiple adjacent components.

Automated Gas Control

Cutting gases are precisely managed via software, ensuring optimal flow, efficiency, and cost savings.

Advanced Piercing Technology

Enhances piercing on thicker materials with dynamic power, frequency, and cutting height adjustments.

*Models and features vary, please see individual product pages for software inclusions and features.

Essentials: Fibre Laser Cutter Extraction Systems

The Cyclone is a compact dry dust collection system specifically designed to enhance the safety and efficiency of fibre laser metal cutting. By capturing and filtering fine metal particles, the Cyclone helps reduce airborne emissions, ensuring a cleaner and safer working environment while also protecting your laser system from harmful dust buildup.

By incorporating the Cyclone Fibre Laser Extraction System, businesses can improve workplace safety, extend machine longevity, and maintain superior cutting performance while ensuring compliance with health and safety regulations.

Key Features

Dry Dust Collection System

- Equipped with high-efficiency filter cartridges to capture and contain metal dust.

- Integrated fan and electrical panel for self-contained operation.

- Plug-and-play design for quick installation and simple maintenance.

Indoor or Outdoor Installation

- Can be installed indoors or externally with an optional protective cowling.

- Versatile placement options for optimal dust removal and air quality improvement.

- Keeps your laser cutter free from harmful deposits, though regular housekeeping is still required.

Compatible With Most Fibre Lasers

- Designed for seamless integration with Mantech’s fibre laser cutter range.

- Also compatible with third-party fibre laser machines, providing an efficient air-cleaning solution for systems without built-in extraction.

Your FAQs Answered

Get in touch If you can't find what you're looking for, contact us.

How much does a fibre laser cutter cost?

The cost of a fibre laser cutter varies significantly depending on factors like laser power, work area size, automation features, and manufacturer. Entry-level machines can start from around £20K, while high-power, fully automated industrial fibre laser cutters can reach 200K plus. For accurate pricing tailored to your specific requirements, we encourage you to:

What maintenance is required for a fibre laser cutter?

Fibre laser cutters generally require less maintenance than CO2 lasers, but regular upkeep is still important. Key maintenance tasks include: cleaning optics, inspecting and cleaning the cutting head, checking coolant levels, lubricating moving parts, and replacing consumables as needed. Mantech Machinery offers preventative maintenance programmes to help you keep your machine in optimal condition.

What materials can a fibre laser cutter cut?

Fibre laser cutters are highly versatile and can cut a wide range of metals, including mild steel, stainless steel, aluminium, copper, brass, titanium, and more. The maximum thickness achievable depends on the laser power and material type.

Contact us to discuss your specific material-cutting needs, and our experts can advise on the appropriate machine and power level.

Does the Fibre Laser Come with Software?

Yes, all of our Fibre Laser Cutters come with integrated software and a built-in PC system for full machine control.

- FL 60/90/130 models – Supplied with a UK-designed fibre laser control system.

- FL250/300 models – Will feature this system following successful beta testing.

- SF models – Equipped with CypCut, CypTube, or HypTube, depending on the model.

If you have specific software requirements or prior experience, our friendly fibre laser sales engineers are happy to assist in finding the best solution for your needs.

What Warranty Do You Offer with Your Fibre Laser Cutters?

All of our Fibre Laser Cutters come with a comprehensive 2-year warranty as standard.

Additionally, we provide lifetime technical support via telephone and email, ensuring you have ongoing access to expert assistance whenever you need it.

Do You Offer Extended Warranties?

Does Mantech Offer Service Agreements?

Yes, we provide customisable service-level agreements (SLAs) to support your Fibre Laser Cutter.

- Available at the time of purchase or anytime afterwards.

- Ensures ongoing maintenance, priority support, and optimal machine performance.

- Contact your Mantech representative or our service team for more details.

Do you have your own engineering team?

All of our engineers are employed by Mantech. We have a large network of road engineers that support our customers throughout the UK, Ireland and Europe.

Interesting Fibre Laser Market Fact!

Fiber Laser Cutter Market by Application (2023)

Source: Global Growth Insights – Fiber Laser Cutting Machine Market Forecast

The global fibre laser cutter market spans a variety of industrial applications, each contributing to the technology’s expanding footprint in modern manufacturing. As of 2023, the largest share belongs to general machinery, where fibre lasers are used for cutting structural components and complex metal forms with speed and precision. The automotive sector follows closely, utilising laser cutting in body panel fabrication, chassis design, and electric vehicle battery production.

Home appliances — including white goods like refrigerators and washing machines — rely on fibre lasers for detailed sheet metal work. Meanwhile, aerospace and marine industries adopt fibre laser cutters for intricate, high-precision parts used in aircraft, ships, and defence components. Finally, other applications, including signage, electronics, and small-scale fabrication, round out the market.

This segmentation highlights the growing versatility of fibre lasers across industries, particularly where precision, speed, and material efficiency are mission-critical.

Keep up with the Latest

Fibre Laser Installations

Jun 23rd

3 weeks ago

Vector FL300 Fibre Laser Installed in Braughing

Jun 16th

4 weeks ago

Vector FL250 Fibre Laser Installed – Power Meets Precision

May 20th

2 months ago

Lasertech 90130 Laser Cutter Installed at UK School – Supporting STEM Learning

Apr 10th

3 months ago

Installation Update – Vector FL90 Fibre Laser in London

Apr 7th

3 months ago

Precision Meets Education – Vector FL90 Installed in Edinburgh

Apr 7th

3 months ago