What is a CNC Router? Benefits for UK Manufacturers

In the world of modern manufacturing, precision and efficiency are key. One technology that has revolutionised production processes across industries is the CNC router. But what exactly is a CNC router, and why should UK manufacturers consider incorporating this powerful tool into their operations? Let’s take a closer look at CNC routers, their benefits, and how they can streamline your manufacturing processes.

What is a CNC Router? And how can manufacturers benefit from them?

A CNC (Computer Numerical Control) router is a cutting-edge machine that uses computer-controlled technology to carve, cut, or engrave materials with high precision. These machines can work with a variety of materials, including wood, plastics, metals, and composites. They follow detailed instructions programmed into them via a computer, allowing for repeatable and accurate production.

Unlike manual routers, which require constant supervision, a CNC router operates autonomously, reducing human error and increasing production efficiency. The versatility of CNC routers makes them ideal for a wide range of applications, from creating intricate designs to producing high-volume parts.

How does a CNC Router work?

CNC routers operate through a three-step process:

- Design and Programming: A designer creates a digital blueprint of the project using specialized software (CAD/CAM).

- Machine Setup: The design file is loaded into the CNC router’s system, and the material is secured on the machine bed.

- Cutting and Engraving: The CNC router follows the instructions from the design file, using a rotating cutter to carve the material according to the specified shape, size, and depth.

This process allows for the creation of highly detailed and customised parts, all while ensuring precision, consistency, and minimal waste.

Benefits of CNC Routers for UK Manufacturers

Increased Precision and Accuracy

One of the standout advantages of CNC routers is their precision. Traditional manual methods can be prone to errors, but with a CNC router, each cut is executed with accuracy. This level of precision is especially crucial for industries that require high tolerances, such as aerospace, automotive, and woodworking.

One of the standout advantages of CNC routers is their precision. Traditional manual methods can be prone to errors, but with a CNC router, each cut is executed with accuracy. This level of precision is especially crucial for industries that require high tolerances, such as aerospace, automotive, and woodworking.

Enhanced Efficiency and Productivity

CNC routers can operate continuously with minimal human intervention. As a result, production time is significantly reduced, allowing manufacturers to meet high demand without compromising on quality. With faster turnaround times, businesses can also take on more projects, leading to increased revenue.

CNC routers can operate continuously with minimal human intervention. As a result, production time is significantly reduced, allowing manufacturers to meet high demand without compromising on quality. With faster turnaround times, businesses can also take on more projects, leading to increased revenue.

Cost-Effective Operations

While the initial investment in a CNC router may seem significant, the long-term savings are undeniable. CNC routers reduce material wastage, minimise errors, and require less manual labor, making them a cost-effective solution in the long run. For manufacturers in the UK, this can translate into improved profit margins.

While the initial investment in a CNC router may seem significant, the long-term savings are undeniable. CNC routers reduce material wastage, minimise errors, and require less manual labor, making them a cost-effective solution in the long run. For manufacturers in the UK, this can translate into improved profit margins.

Versatility Across Materials

CNC routers can handle a variety of materials, from soft woods to tough metals. This versatility makes them an ideal choice for industries as diverse as furniture making, signage, automotive, and even aerospace. Whether you’re crafting intricate wood carvings or cutting precise metal parts, a CNC router can handle it all.

CNC routers can handle a variety of materials, from soft woods to tough metals. This versatility makes them an ideal choice for industries as diverse as furniture making, signage, automotive, and even aerospace. Whether you’re crafting intricate wood carvings or cutting precise metal parts, a CNC router can handle it all.

Automation and Reduced Labour Costs

By automating the manufacturing process, CNC routers reduce the need for manual labour. This leads to fewer operational costs and minimises the risk of human error. Automation also allows workers to focus on other critical tasks while the CNC router handles repetitive cutting and engraving.

By automating the manufacturing process, CNC routers reduce the need for manual labour. This leads to fewer operational costs and minimises the risk of human error. Automation also allows workers to focus on other critical tasks while the CNC router handles repetitive cutting and engraving.

Customisation and Complex Designs

CNC routers can easily produce complex shapes and customised designs that would be challenging with manual tools. Whether you’re producing unique pieces or mass-producing identical parts, CNC routers offer the flexibility to meet your design specifications with ease.

CNC routers can easily produce complex shapes and customised designs that would be challenging with manual tools. Whether you’re producing unique pieces or mass-producing identical parts, CNC routers offer the flexibility to meet your design specifications with ease.

Why Should UK Manufacturers Invest in CNC Routers?

The manufacturing industry in the UK is becoming increasingly competitive, and businesses need to stay ahead of the curve by adopting innovative technologies. CNC routers provide an edge by improving production efficiency, precision, and the overall cost-effectiveness of operations.

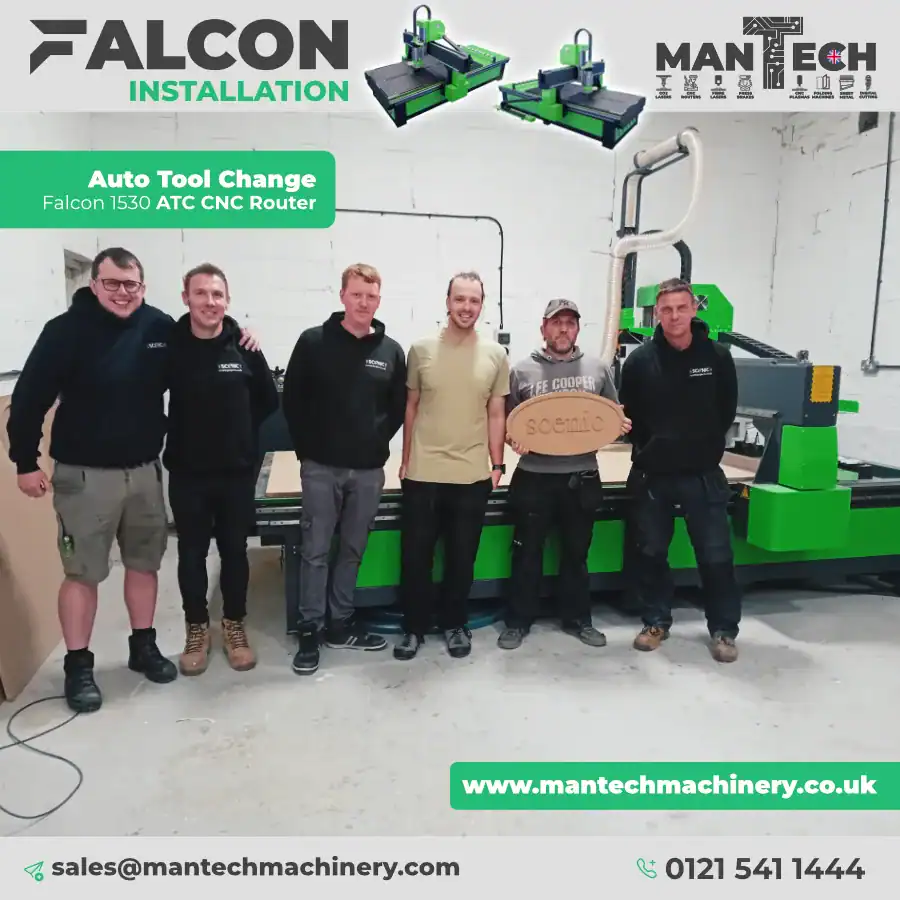

At Mantech, we offer a wide range of CNC routers that are designed to meet the specific needs of manufacturers in various sectors. Our machines offer advanced features that enable manufacturers to maximise productivity while maintaining the highest quality standards.

By incorporating a CNC router into your operations, you can streamline processes, reduce waste, and enhance product quality—helping your business remain competitive in the ever-evolving UK manufacturing landscape.

Conclusion

In summary, a CNC router is a versatile and powerful tool that offers numerous benefits for UK manufacturers. From precision cutting to increased productivity and cost-effectiveness, it can transform your production process and give your business a competitive advantage. If you’re looking to elevate your manufacturing capabilities, investing in a CNC router could be the smart next step.

By leveraging the advanced technology of CNC routers, businesses can improve their production processes, reduce costs, and enhance product quality. Mantech Machinery offers high-performance CNC routers that can help UK manufacturers achieve these goals, making them an essential addition to any modern manufacturing operation.

CNC Routers