Why are CO2 Laser Cutters so Popular With Crafters and Makers

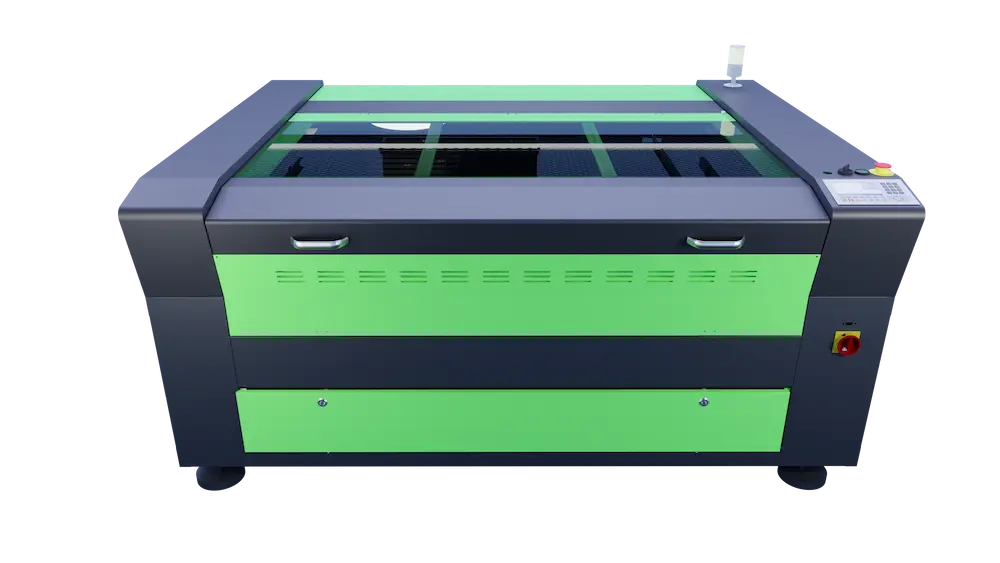

Introduction to CO2 Laser Cutters

How a CO2 Laser Cutter Works

Why Crafters and Makers Love CO2 Laser Cutters

Precision and Accuracy

Versatility

Material Compatibility

Cutting and Engraving Capabilities

Ease of Use

Economic Benefits of CO2 Laser Cutters

Cost Efficiency

Maintenance and Durability

Safety and Environmental Considerations

Safety Features

Most reputable firms also supply an air filtration system as an option, something like a Purex or BOFA.

Conclusion

FAQs

What materials can a CO2 laser cutter work with?

A CO2 laser cutter is incredibly versatile and can work with a broad range of materials. This includes but is not limited to wood, acrylic, glass, leather, rubber, plastics, and certain metals (such as removing the anodisation layer or using a chemical etching spray or paste). Always ensure to check your machine’s specific capabilities and the material’s safety for laser cutting.

How accurate are CO2 laser cutters?

CO2 laser cutters are renowned for their precision and accuracy. They can cut and engrave intricate designs with minimal error margins, down to fractions of a millimetre. This high accuracy makes them an excellent tool for detailed crafting and manufacturing work

Are CO2 laser cutters easy to use for beginners?

es, while they may seem intimidating at first, modern CO2 laser cutters are designed with user-friendly interfaces that are suitable even for beginners. Many machines also come with supportive software and detailed instructions, making the learning curve manageable. However, like any new tool, it requires some practice and patience to master. Remember with a machine from Mantech you also have access to our training upon installation (which is included in the sale).

Are CO2 laser cutters cost-efficient?

Indeed, CO2 laser cutters are cost-effective in several ways. They offer high precision which minimises waste, resulting in better material utilisation. Additionally, they have quick operation times, which can significantly increase productivity and efficiency. The machine’s durability, with proper maintenance, also means a one-time investment for years of use.

What safety features do CO2 laser cutters have?

Safety is a significant aspect of CO2 laser cutters. They commonly feature safety measures such as an emergency stop function that allows the user to stop the machine’s operation immediately. Some models also include safety interlocks and protective housing to prevent accidental exposure to the laser beam.