Incredible Ultra High-Powered Fibre Laser Cutters - Upto 60kW.

Extreme Cutting Power

Expansive Cutting Areas

Precision & Speed Performance

Full UK Warranty

Delivery Included

Installation Included

12-60kW of Power

Exceptional Service

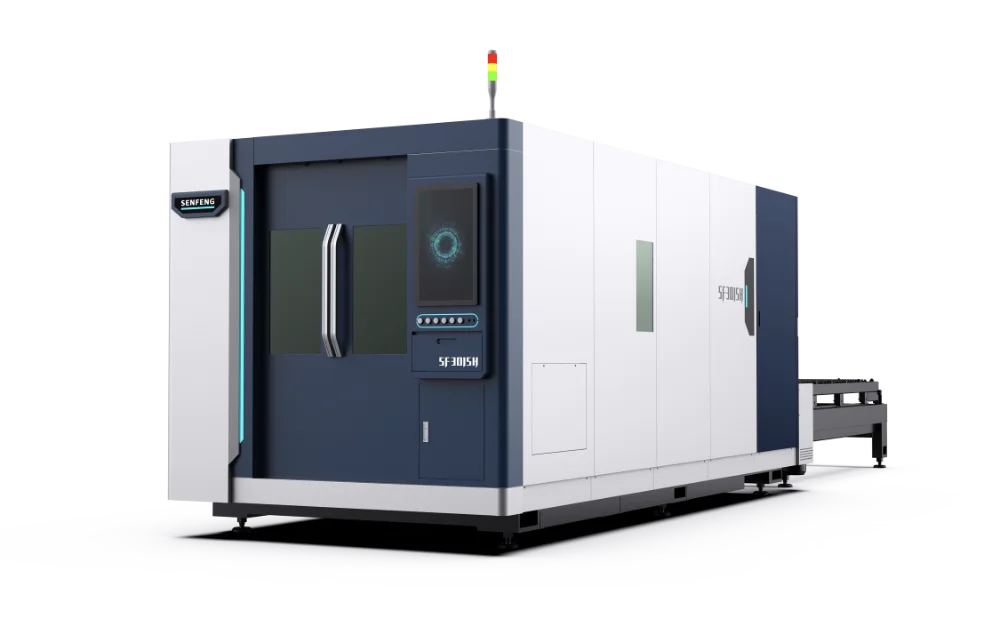

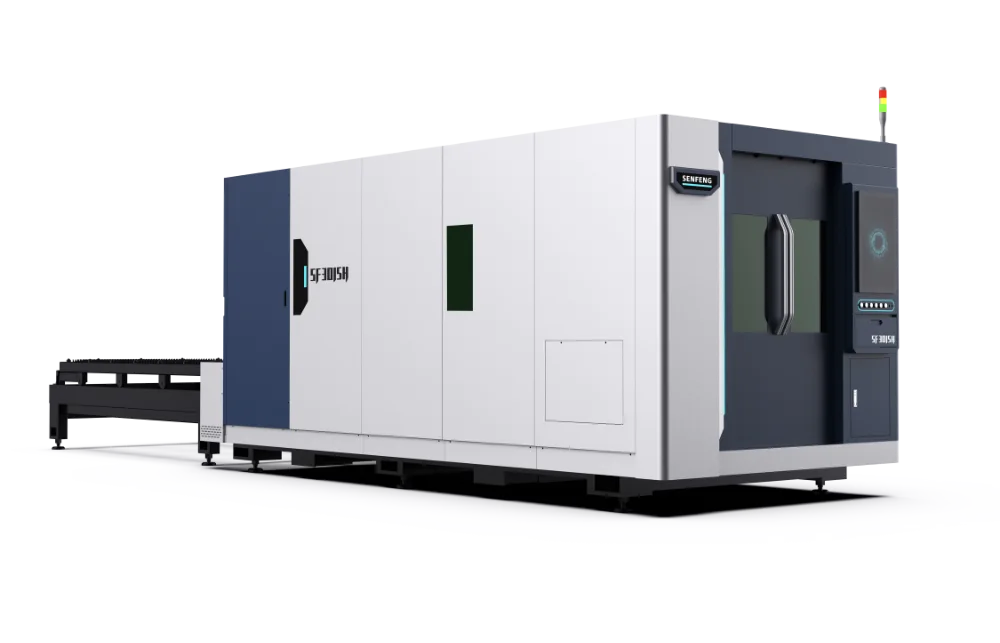

Unrivalled Fibre Laser Cutting Performance - SF Ultra High Power Gen 5

Unrivalled Performance: SF Ultra High Powered Fibre Laser Series.

Experience the Ultimate in Power & Precision With The SF H Gen 5 Fibre Laser Series

The series features auto-exchange shuttle tables, enabling continuous operation and maximising productivity. Additionally, the SF H Gen 5 boasts a maximum acceleration rate of up to 2.8G and processing lengths of up to 12.1 meters, ensuring exceptional performance for large-scale projects.

Fully Featured

Ultra Powerful Metal Cutting

Dual Shuttle Exhange Tables

Overview and Features

| SF Ultra High Power Fibre Datasheet | Description |

|---|---|

| Cutting table sizes | 3050x1530 | 4050x2030 | 6050x2030 | 8050x2530 | 12100x2530 |

| Table type | Low contact cutting table |

| Shuttle Exchange Table | Yes - dual shuttle exchange tables included |

| Laser Power Options | 2kW | 15kW | 20kW | 30kW | 40kW | 50kW | 60kW options |

| Positioning Accuracy (X,Y axis) | ±0.05 mm |

| Repeat Positioning Accuracy (X,Y axis) | ±0.02 mm |

| Max Speed | 200 m/min |

| Max Acceleration | 2.8G |

| Safety Enclosure | Yes – full safety enclosure to protect your operators from any stray beams and to aid in the safe extraction of cutting vapour |

| Laser Cutting Head | Raytools - Autofocus |

| Servo Drives | High-accuracy servo-driven system |

| Drive System | Double Y axis ball screw transmission |

| Guide Rails | HIWIN guide rails |

| Ball Screw | TBI ball screw |

| Dual Channel Water Chiller | Yes - S&A CWFL Series (model is power dependant) |

| CNC Controller | Cypcut CNC control |

| Software Included | Yes - integrated CAD package for on-machine file creation/editing |

| Consumables | Yes - set of protective lens, focus lens, and nozzle pack supplied (additional available to purchase) |

| Power requirements | 3 Phase AC 380V 50HZ |

| Delivery and installation | Included (offloading and positioning are available upon request). Installation and training included |

| Chiller Dimensions | S&A Model to Suite |

| Length | 550 mm |

| Depth | 770 mm |

| Height | 1030 mm |

| Weight | Appx 95kg |

Why Choose The SF H Gen 4 Fibre Laser Range?

The SF H Gen 5 Fibre Laser Cutter represents the pinnacle of industrial laser cutting, engineered for businesses demanding maximum power, speed, and precision. With laser power options ranging from 12kW to an industry-leading 60kW, it is built to handle the toughest materials and thickest cuts with ease. Designed for high-performance manufacturing, it ensures exceptional accuracy and efficiency, making it the ideal choice for heavy-duty industrial applications.

Unmatched Productivity & Cutting Performance

Equipped with auto-exchange shuttle tables and a staggering acceleration rate of up to 2.8G, the SF H Gen 5 minimises downtime and optimises workflow efficiency. Capable of handling cutting lengths of up to 12.1 meters, it is engineered for large-scale, high-speed production with flawless precision.

Advanced Engineering for Industrial Strength & Stability

Heavy-Duty Thermal-Isolated Bed Structure

Designed for long-term durability, the SF H Gen 5’s bed is constructed from high-quality steel plates and pipes, undergoing:

- Stress relief annealing & secondary ageing treatment for unmatched stability.

- Precision machining using ultra-large gantry milling, eliminating deformation over time.

- Graphite and copper protection (on models 8kW and above) for enhanced heat resistance.

- Dual exchange platforms with deviation correction, ensuring ultra-precise cutting performance.

Aerospace-Grade Aluminium Gantry Beam

The SF H Gen 5 features an aircraft-grade aluminium beam, delivering:

- Lightweight yet high-strength design, reducing inertia for faster movement.

- Triangular reinforced structure, enhancing rigidity and shock resistance.

- Advanced two-stage machining process (annealing & vibration ageing) for optimal structural integrity and accuracy.

Is Training & Delivery Included?

Yes! All SF Fibre Laser Cutters include:

✔ UK mainland delivery as standard

✔ Full professional installation

✔ Comprehensive training to ensure seamless operation

The SF H Gen 5 is the ultimate solution for industrial laser cutting, delivering unrivalled power, precision, and productivity.

| Metals |

|---|

| Stainless Steel |

| Mild and Carbon Steel |

| Copper |

| Brass |

| Aluminium |

| Titanium |

Fibre Laser Installations

Vector FL250 Fibre Laser Cutter Installation – West Yorkshire

New Vector FL250 Fibre Laser Installation – Wokingham (3kW Configuration)

SF3015 3kW Fibre Laser Installation – Wednesbury, West Midlands

Not sure which Fibre Laser model is right for you? Our team can help.