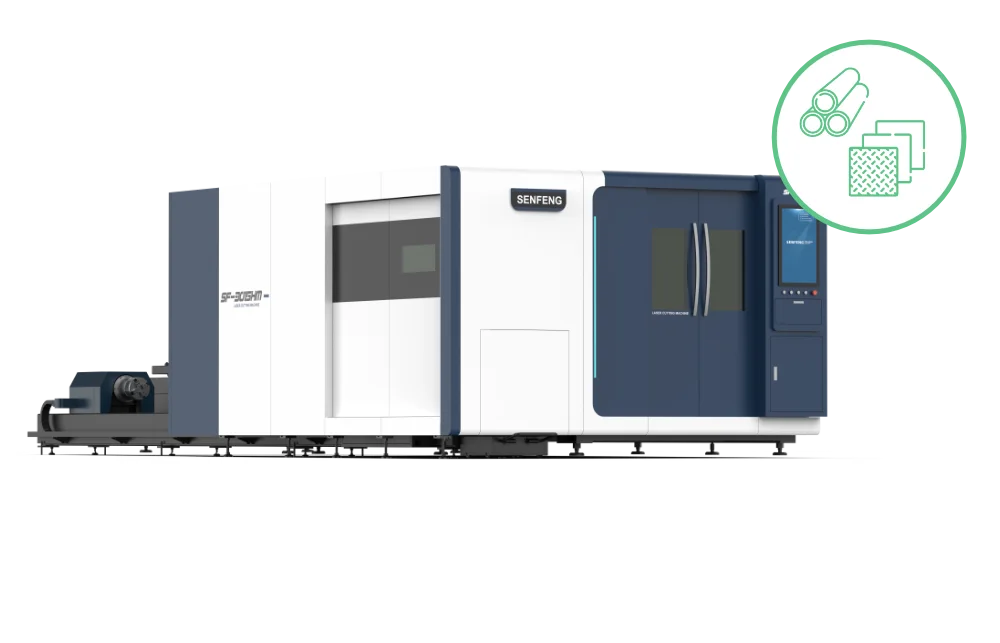

SF Combination Fibre Laser Cutter for Sheet & Tube Cutting

Multi-Purpose Fibre Laser Cutter for Sheet & Tube Processing

Space-Saving Combination Laser System

Consistent Cutting Performance with Intuitive Operation

Full UK Warranty

Delivery Included

Installation Included

1.5-6kW Power Options

Flat Plate & Tube Cutting

Dual Purpose Fibre Laser - Cut Both Sheet & Tube with One System

SF Combination Fibre Laser Cutter - Precision & Versatility in One Machine.

Overview and Features

| SF HM Combination Fibre Laser Datasheet | Description |

|---|---|

| Cutting table sizes | 3050 x 1530 | 4050 x 2030 | 6050 x 1530 | 6050 x 2030 | 6050 x 2530 |

| Table type | Low contact cutting table |

| Shuttle Exchange Table | Yes - dual shuttle exchange tables included |

| Laser Power Options | 1.5kW | 3kW | 6kW options |

| Rotary Indexer | Yes - 6m module |

| Positioning Accuracy (X,Y axis) | ±0.05 mm |

| Repeat Positioning Accuracy (X,Y axis) | ±0.02 mm |

| Max Speed | 130 m/min |

| Max Acceleration | 1.0G |

| Safety Enclosure | Yes – full safety enclosure to protect your operators from any stray beams and to aid in the safe extraction of cutting vapour |

| Laser Cutting Head | Raytools - Autofocus |

| Servo Drives | High-accuracy servo-driven system |

| Drive System | Double Y axis ball screw transmission |

| Guide Rails | HIWIN guide rails |

| Ball Screw | TBI ball screw |

| Dual Channel Water Chiller | Yes - S&A CWFL Series (model is power dependant) |

| CNC Controller | Cypcut CNC control |

| Software Included | Yes - integrated CAD package for on-machine file creation/editing |

| Consumables | Yes - set of protective lens, focus lens, and nozzle pack supplied (additional available to purchase) |

| Power requirements | 3 Phase AC 380V 50HZ |

| Delivery and installation | Included (offloading and positioning are available upon request). Installation and training included |

| Chiller Dimensions | S&A Model to Suite |

| Length | 550 mm |

| Depth | 770 mm |

| Height | 1030 mm |

| Weight | Appx 95kg |

Why Choose The SF HM Combination Fibre Laser Range?

The SF HM Combination Fibre Laser Cutter is a high-performance, dual-purpose system designed to streamline fabrication by integrating flat plate and tube cutting within a single machine. This versatile solution eliminates the need for multiple machines, optimising workflow and maximising productivity for manufacturers in metal processing, engineering, and industrial production.

Multi-Functionality for Enhanced Efficiency

- Seamlessly switch between sheet metal cutting and tube/profile processing, improving efficiency and reducing production time.

- Compact footprint saves valuable workshop space while delivering high-powered cutting performance.

- Advanced user-friendly software ensures precise control and optimised cutting for various materials and thicknesses.

Engineered for Industrial-Grade Performance

- Cutting power options from 1.5kW to 6kW cater to a wide range of fabrication needs.

- Built with high-quality components and a durable design for long-term reliability.

- Fast shuttle exchange table enables continuous cutting and minimal downtime.

- Available in multiple bed sizes to suit specific production requirements.

Safe & Efficient Operation

- Fully enclosed design ensures a safe working environment by containing laser emissions and metal particulates.

- Integrated fume extraction system effectively removes hazardous vapours, maintaining workplace safety.

Is Training and Delivery Included?

Yes, all of our Fibre Laser Cutters include UK mainland delivery as standard. We also provide comprehensive operator training to ensure you can confidently run your new machine from day one.

| Metals |

|---|

| Stainless Steel |

| Mild and Carbon Steel |

| Copper |

| Brass |

| Aluminium |

| Titanium |

Fibre Laser Installations - Latest

Vector FL250 Fibre Laser Cutter Installation – West Yorkshire

New Vector FL250 Fibre Laser Installation – Wokingham (3kW Configuration)

SF3015 3kW Fibre Laser Installation – Wednesbury, West Midlands

Not sure which Fibre Laser model is right for you? Our team can help.