Zero-Tailing 3-Chuck Tube Fibre Laser Cutters for Precision Tube Processing

Versatile Tube Cutting for Complex Profiles

Zero-Tailing Design for Maximum Material Utilisation

High-Speed Precision with Advanced CNC Technology

Full UK Warranty

Delivery Included

Installation Included

1-9 mtr Tube Length

350 mm Dia Tube (max)

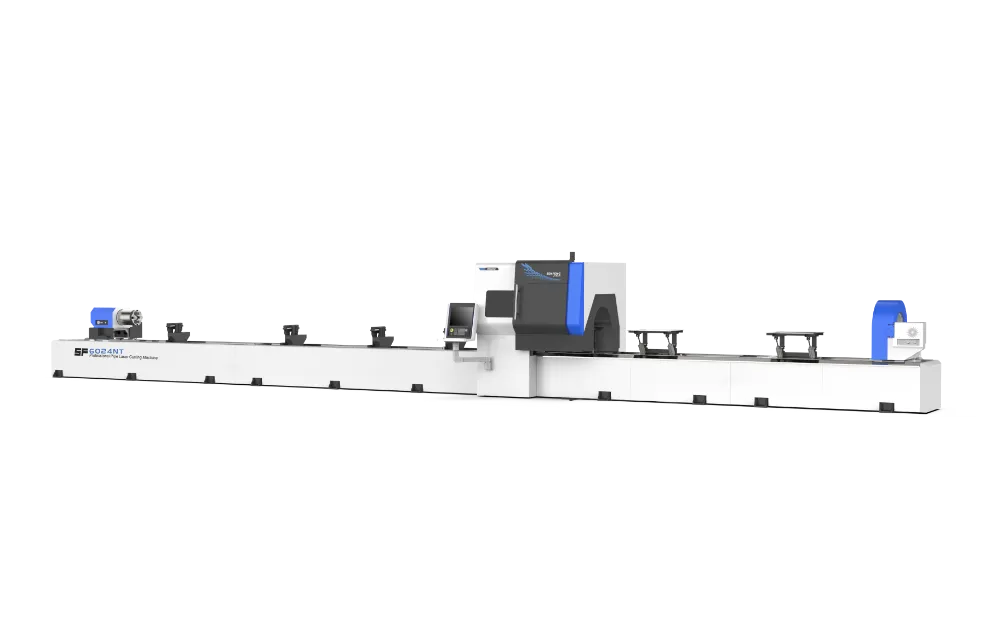

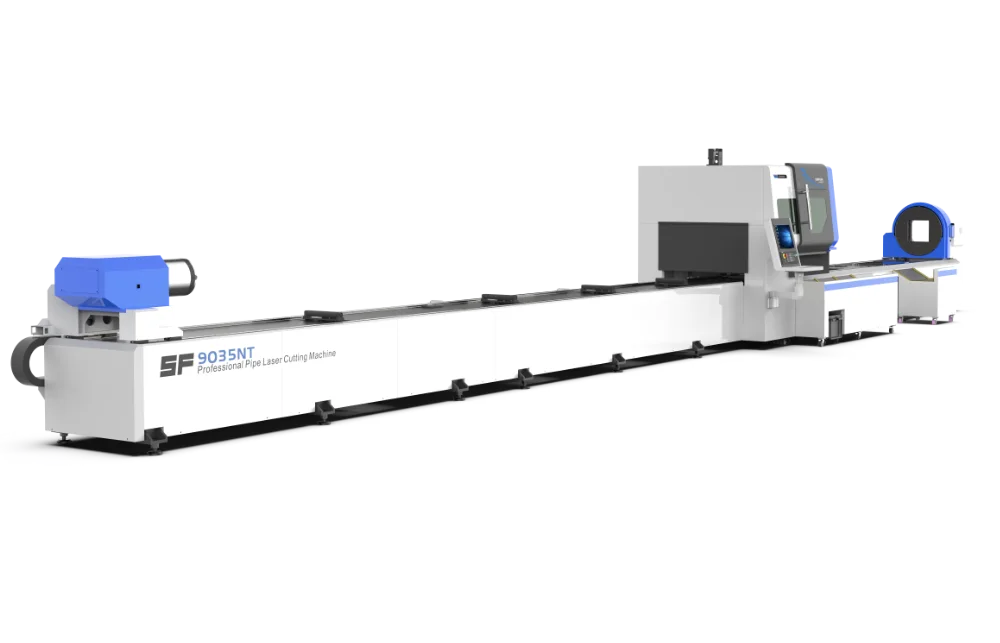

High-Performance 9-Metre Zero Tailing Tube Laser Cutter

SF 9035NT X3 Chuck Tube Laser - Precision & Zero Waste Cutting

Overview and Features

| SF 9035NT Tube Laser Datasheet | Description |

|---|---|

| Capacity | 9 meters x 350 mm dia chuck design |

| Chuck System | Zero tail x3 chuck system |

| Laser Power Options | 1.5kW | 2kW | 3kW | 4kW | 6kW options |

| Pipe Processing Range (Round Tube) | φ20-φ350mm |

| Pipe Processing (Square Tube) | 20×20~350×350mm |

| Positioning Accuracy (X,Y axis) | ±0.01 mm |

| Repeat Positioning Accuracy (X,Y axis) | ±0.03 mm |

| Max Speed | 80 m/min |

| Max Chuck Speed | 750 r/min |

| Max Acceleration | 0.6G |

| Max Table Load | 700kg |

| Safety Enclosure | Yes – safety enclosure to protect your operators from any stray beams and to aid in the safe extraction of cutting vapour. Safety fencing options. |

| Laser Cutting Head | Raytools - Autofocus |

| Servo Drives | High-accuracy servo-driven system |

| Dual Channel Water Chiller | Yes - S&A CWFL Series (model is power dependant) |

| CNC Controller | Cypcut/Cyptube |

| Software Included | Cyptube/Tubest 3D Nesting |

| Consumables | Yes - set of protective lens, focus lens, and nozzle pack supplied (additional available to purchase) |

| Power requirements | 3 Phase AC 380V 50HZ |

| Delivery and installation | Included (offloading and positioning are available upon request). Installation and training included |

| Chiller Dimensions | S&A Model to Suite |

| Length | 550 mm |

| Depth | 770 mm |

| Height | 1030 mm |

| Weight | Appx 95kg |

Why Choose The SF 9035NT Tube Fibre Laser Range?

The SF 9035NT Tube Laser Cutter is engineered for precision, efficiency, and maximum material utilisation. Its cutting-edge three-chuck design ensures stability, zero tailing, and reduced waste, making it a highly cost-effective choice for businesses focused on high-volume tube processing.

Zero Tailing for Maximum Efficiency

This innovative machine eliminates leftover material at the ends of tubes, optimising raw material use and significantly lowering production costs. With the ability to handle tubes up to 9 meters in length and 350mm in diameter, it is ideal for industrial applications requiring high-precision cuts.

Versatile Tube & Profile Cutting Capabilities

The SF 9035NT accommodates a wide range of profiles, including round, square, rectangular, and complex geometries such as L, U, and H profiles. This versatility makes it a perfect solution for industries such as aerospace, automotive, construction, and custom metal fabrication.

Advanced CNC Control & 3D Nesting Software

Equipped with an advanced CNC control system and integrated 3D nesting software, the SF 9035NT simplifies the cutting process. Operators can execute intricate designs with minimal setup time, ensuring high-speed, precision cutting for even the most complex tube configurations.

Optimised Cutting Accuracy with Real-Time Compensation

The SF 9035NT features dynamic, real-time centre deviation compensation, significantly enhancing perforation accuracy on tubular materials. Customisable corner-cutting technology refines edges for a cleaner, more professional finish, ensuring superior product quality in every batch.

Enhanced Operator Safety & Clean Work Environment

A fully enclosed cutting area protects operators while containing metal dust and laser radiation. This ensures a cleaner, safer workspace, meeting industry safety regulations and improving operational efficiency.

Is Training and Delivery Included?

Yes, all of our Fibre Laser Cutters include standard UK mainland delivery and comprehensive training. Our expert engineers will guide you through machine operation and software usage, ensuring you are fully equipped to maximise your new laser cutter’s potential.

| Metals |

|---|

| Stainless Steel |

| Mild and Carbon Steel |

| Copper |

| Brass |

| Aluminium |

| Titanium |

Fibre Laser Installations - Latest

Vector FL250 Fibre Laser Cutter Installation – West Yorkshire

New Vector FL250 Fibre Laser Installation – Wokingham (3kW Configuration)

SF3015 3kW Fibre Laser Installation – Wednesbury, West Midlands

Not sure which Fibre Laser model is right for you? Our team can help.