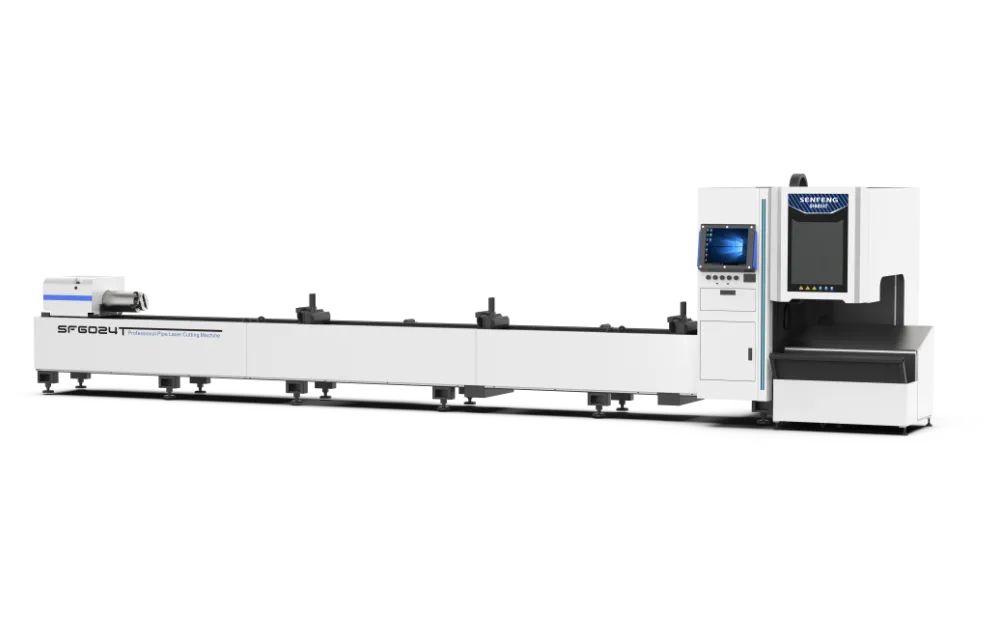

Affordable 2-Chuck Tube Fibre Laser Cutters for Precision Metal Tube Cutting

High-Strength Bed for Stable, Accurate Cutting

Flexible Cutting Lengths & Power Options

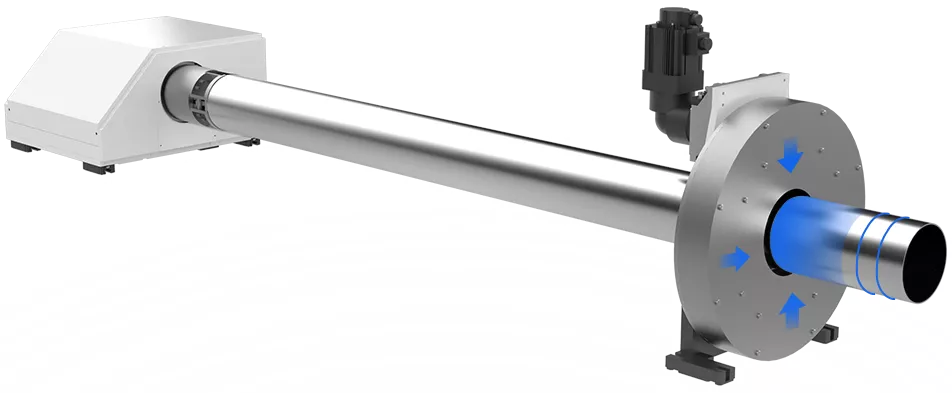

Pneumatic Auto-Clamping for Efficient Setup

Full UK Warranty

Delivery Included

Installation Included

6 & 9 mtr Options

220/240/350 mm Diameter Max (Round Tube)

A Versatile 6 or 9 Metre System - Engineered for a Wide Range of Sectors

Overview and Features

| SF 6000T Series Tube Laser Datasheet | Description |

|---|---|

| SF6020T | |

| Capacity | 6-meter standard with nine available as an option |

| Chuck System | X2 pneumatic chuck system |

| Laser Power Options | 1.5kW | 2kW | 3kW | 4kW | 6kW options |

| Pipe Processing Range (Round Tube) | φ10-φ220mm |

| Pipe Processing (Square Tube) | 10×10-150×150mm |

| Positioning Accuracy (X,Y axis) | ±0.05 |

| Repeat Positioning Accuracy (X,Y axis) | ±0.02 mm |

| Max Chuck Speed | 100 r/min |

| Max Acceleration | 1.0G |

| Max Table Load | 150kg |

| Safety Enclosure | Yes – safety enclosure to protect your operators from any stray beams and to aid in the safe extraction of cutting vapour. Safety fencing options. |

| Laser Cutting Head | Raytools - Autofocus |

| Servo Drives | High-accuracy servo-driven system |

| Dual Channel Water Chiller | Yes - S&A CWFL Series (model is power dependant) |

| CNC Controller | Cypcut/Cyptube |

| Software Included | Cyptube/Tubest 3D Nesting |

| Consumables | Yes - set of protective lens, focus lens, and nozzle pack supplied (additional available to purchase) |

| Power requirements | 3 Phase AC 380V 50HZ |

| Delivery and installation | Included (offloading and positioning are available upon request). Installation and training included |

| SF 6024T | |

| Capacity | 6-meter standard with nine available as an option |

| Chuck System | X2 pneumatic chuck system |

| Laser Power Options | 1.5kW | 2kW | 3kW | 4kW | 6kW options |

| Pipe Processing Range (Round Tube) | φ20-φ240mm |

| Pipe Processing (Square Tube) | 20×20-240×240mm |

| Positioning Accuracy (X,Y axis) | ±0.05 |

| Repeat Positioning Accuracy (X,Y axis) | ±0.03 mm |

| Max Chuck Speed | 100 r/min |

| Max Acceleration | 0.8G |

| Max Table Load | 250kg |

| Safety Enclosure | Yes – safety enclosure to protect your operators from any stray beams and to aid in the safe extraction of cutting vapour. Safety fencing options. |

| Laser Cutting Head | Raytools - Autofocus |

| Servo Drives | High-accuracy servo-driven system |

| Dual Channel Water Chiller | Yes - S&A CWFL Series (model is power dependant) |

| CNC Controller | Cypcut/Cyptube |

| Software Included | Cyptube/Tubest 3D Nesting |

| Consumables | Yes - set of protective lens, focus lens, and nozzle pack supplied (additional available to purchase) |

| Power requirements | 3 Phase AC 380V 50HZ |

| Delivery and installation | Included (offloading and positioning are available upon request). Installation and training included |

| SF 6035T | |

| Capacity | 6-meter standard with nine available as an option |

| Chuck System | X2 pneumatic chuck system |

| Laser Power Options | 1.5kW | 2kW | 3kW | 4kW | 6kW options |

| Pipe Processing Range (Round Tube) | φ20-φ350mm |

| Pipe Processing (Square Tube) | 20×20-350×350mm |

| Positioning Accuracy (X,Y axis) | ±0.05 |

| Repeat Positioning Accuracy (X,Y axis) | ±0.03 mm |

| Max Chuck Speed | 100 r/min |

| Max Acceleration | 0.6G |

| Max Table Load | 700kg |

| Safety Enclosure | Yes – safety enclosure to protect your operators from any stray beams and to aid in the safe extraction of cutting vapour. Safety fencing options. |

| Laser Cutting Head | Raytools - Autofocus |

| Servo Drives | High-accuracy servo-driven system |

| Dual Channel Water Chiller | Yes - S&A CWFL Series (model is power dependant) |

| CNC Controller | Cypcut/Cyptube |

| Software Included | Cyptube/Tubest 3D Nesting |

| Consumables | Yes - set of protective lens, focus lens, and nozzle pack supplied (additional available to purchase) |

| Power requirements | 3 Phase AC 380V 50HZ |

| Delivery and installation | Included (offloading and positioning are available upon request). Installation and training included |

| Chiller Dimensions | (S&A Model) |

| Length | 550 mm |

| Depth | 770 mm |

| Height | 1030 mm |

| Weight | Appx 95kg |

Why Choose The SF 6000T Tube Fibre Laser Range?

Precision, Efficiency & Versatility in Tube Cutting

The SF 6000T Tube Fibre Laser Cutter is designed for high-precision processing of tubes up to 6 meters in length, making it ideal for construction, fabrication, and manufacturing industries. Featuring a dual-chuck system, this machine delivers exceptional stability and cutting accuracy, capable of handling round, square, rectangular, and complex profiles with ease.

Powerful Cutting Performance & Smart Control

With cutting power options from 1.5kW to 3kW, the SF 6000T provides precise, clean cuts across a variety of materials. Equipped with the Cypcut/Cyptube control system, it streamlines operations, minimises material waste, and ensures seamless workflow management. Whether you’re working on large-scale projects or intricate designs, this tube laser offers the flexibility and precision needed to meet demanding production requirements.

Advanced Support System for Consistent Accuracy

This machine features an automated pipe support system, which actively adjusts to maintain stability and precision during long pipe processing. It eliminates errors caused by sagging materials, ensuring consistent cut quality and higher accuracy.

Self-Centering Chuck for Optimal Clamping

The self-centering chuck system automatically adjusts to hold tubes securely, reducing vibration and misalignment for improved precision.

Optional Auto-Loading & Unloading for High-Volume Production

For manufacturers seeking automated efficiency, the SF 6000T offers optional auto-loading and unloading modules, transforming it into a fully automated production partner.

Built for Industrial Applications

The SF 6000T Tube Laser Cutter is engineered for high-performance cutting of tubular materials, accommodating diameters of up to 350mm (model dependent) and tube lengths of up to 9 meters. It features pneumatic chucks, high-strength beds, and support wheels, ensuring reliable performance across construction, oil & gas, and heavy fabrication industries.

Seamless Cutting Precision & Real-Time Adjustments

With real-time deviation correction, this system optimises perforation accuracy and corner cutting, ensuring a flawless finish with every cut.

Training & Delivery Included

All of our Fibre Laser Cutters include UK mainland delivery and full operator training, ensuring you and your team can start production immediately and with confidence.

| Metals |

|---|

| Stainless Steel |

| Mild and Carbon Steel |

| Copper |

| Brass |

| Aluminium |

| Titanium |

Request a Quick Quotation

Fibre Laser Installations - Latest

Vector FL250 Fibre Laser Cutter Installation – West Yorkshire

New Vector FL250 Fibre Laser Installation – Wokingham (3kW Configuration)

SF3015 3kW Fibre Laser Installation – Wednesbury, West Midlands

Not sure which Fibre Laser model is right for you? Our team can help.