Your Guide to Fibre Laser Cutting: How It Works & What You Can Cut

Fibre laser cutting has transformed the metal fabrication industry, offering unmatched precision, speed, and cost efficiency. Whether you’re a small workshop looking to modernise or a large-scale manufacturer seeking to streamline production, understanding how fibre laser technology works—and what it can do—can help you make smarter, more profitable decisions.

In this guide, we’ll cover the essentials: what fibre laser cutting is, how it works, what materials it can cut, and why it’s become a game-changer in manufacturing.

What Is Fibre Laser Cutting?

Fibre laser cutting is a high-speed, non-contact cutting process that uses a laser beam generated by a fibre-optic source. The laser is focused into an ultra-fine point, creating a powerful beam of light capable of cutting through a wide range of metals with remarkable precision.

Unlike traditional CO₂ lasers, fibre lasers have higher energy efficiency, lower maintenance requirements, and longer service life, making them ideal for continuous industrial use.

How Does It Work?

Here’s a simplified breakdown of the fibre laser cutting process:

Laser Generation

The laser beam is created within a fibre-optic cable doped with rare-earth elements, such as ytterbium. This beam is then amplified and directed toward the cutting head.

Focusing the Beam

A series of lenses and mirrors focuses the laser to a microscopic point, generating temperatures over 1,000°C at the cutting surface.

Cutting Action

The focused beam melts or vaporises the material, while a high-pressure assist gas (typically nitrogen or oxygen) blows away molten material, leaving a clean, burr-free edge.

Motion Control

CNC (Computer Numerical Control) software guides the laser head with pinpoint precision across the workpiece, enabling complex shapes and fine detailing.

What Materials Can Fibre Lasers Cut?

Fibre laser systems excel in cutting a broad range of metals with varying thicknesses – the below are typical material types and thicknesses (machine and power source dependent – some of our high-powered systems will cut materials thicker than the table below ):

| Material | Max Thickness (Typical) | Notes |

| Mild Steel | Up to 25mm | Clean, high speed cuts |

| Stainless Steel | Up to 20mm | Smooth edges, ideal for food grade applications |

| Aluminium | Up to 15mm | Requires Nitrogen assist gas for clean edges |

| Copper & Brass | Up to 10mm | Fibre lasers can cut reflective metals efficiently |

| Titanium | Varies | Popular in aerospace and medical fields |

Why Fibre Laser Cutting Is Revolutionising Fabrication

Fibre laser cutters are rapidly becoming the go-to solution in manufacturing for several reasons:

- Exceptional Accuracy: Tolerances as tight as ±0.1mm.

- High Cutting Speeds: Significantly faster than plasma or CO₂ systems.

- Minimal Maintenance: No mirrors, lenses, or moving parts in the laser source.

- Lower Operating Costs: Energy-efficient and longer-lasting components.

- Automated Integration: Easily paired with feeding systems and CNC automation for higher productivity.

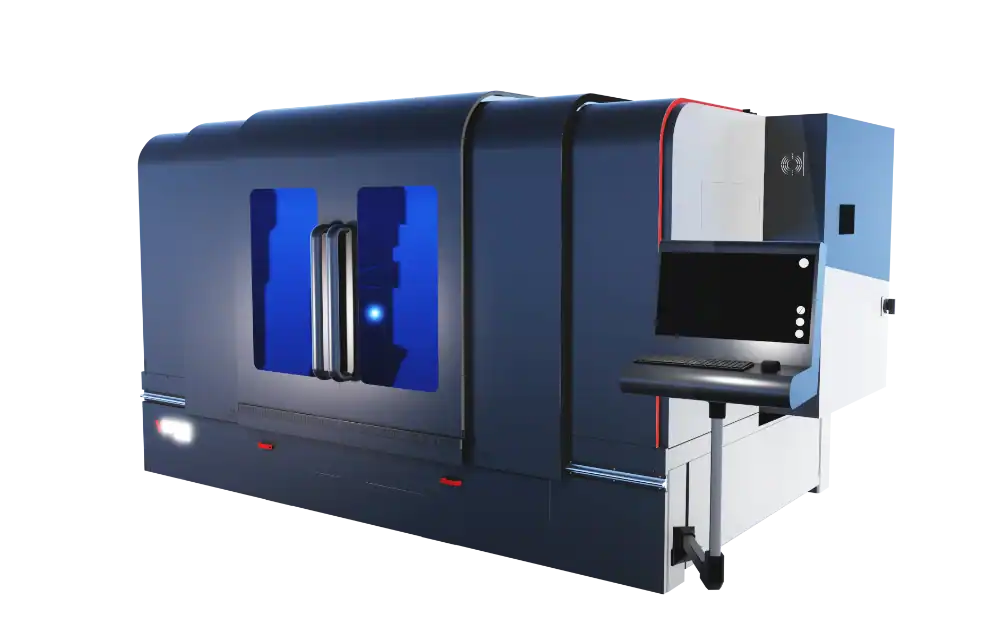

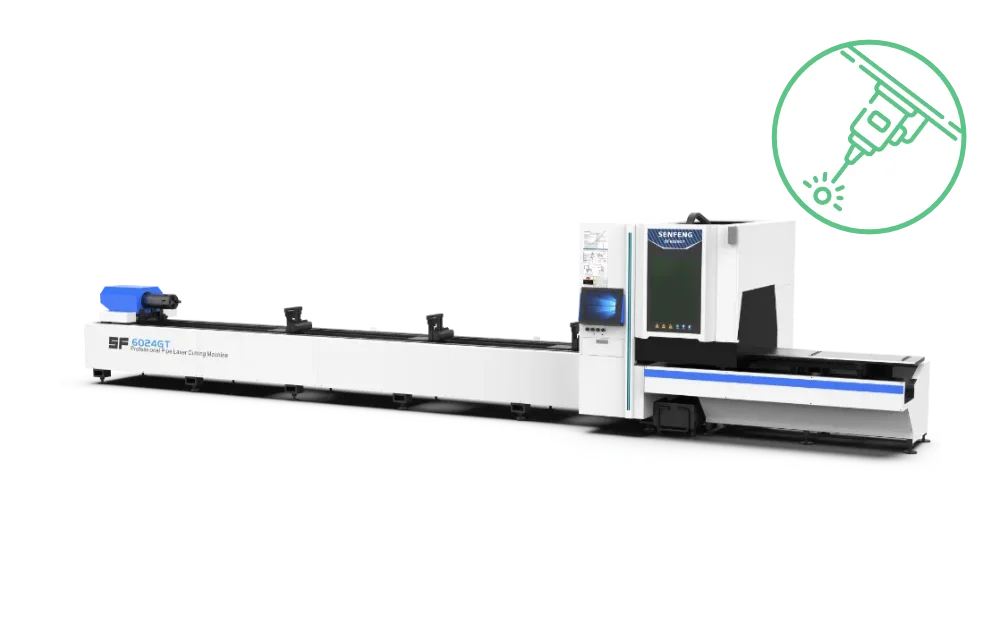

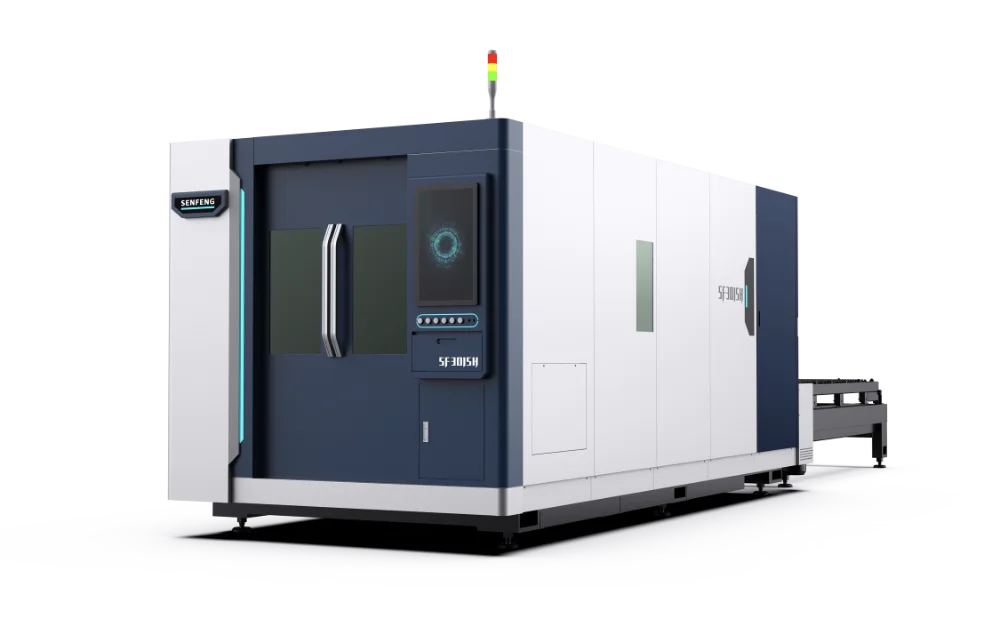

Choosing the Right Fibre Laser Cutter

If you’re exploring fibre laser cutters for your business, consider factors such as bed size, power rating, software capabilities, and after-sales support.

At Mantech Machinery, we offer a range of fibre laser cutters engineered for precision, reliability, and performance. Whether you need a compact model for sheet metal jobs or a high-powered industrial unit for heavy fabrication, our UK-designed machines are trusted by fabricators nationwide.

? Explore the full range of Mantech fibre laser cutters here.

Ideal Applications in Metal Fabrication

Fibre laser cutters are suitable for:

- Sheet metal fabrication

- Automotive parts production

- Architectural and decorative metalwork

- Aerospace components

- Metal signage and enclosures

If you’re working with metals, a fibre laser cutter can give you a competitive edge through precision, speed, and versatility.

Is Fibre Laser Cutting Right for You?

Fibre laser technology is not just a trend—it’s an essential tool for modern metal fabrication. Whether you’re just starting or upgrading your production line, understanding how fibre laser cutting works and what it can do will help you stay ahead of the curve.

Looking for expert advice or a custom recommendation? Talk to the team at Mantech—we’re here to help you choose the best solution for your fabrication needs.

Fibre Laser