The UK's Leading CNC Router Supply and Installation Expert

Delivery Provided as Standard

Installation Included

Software Included

Training Included

Extraction & Vacuum Included

UK Warranty Included

Affordable, High Performance CNC Routers Coupled With First Class Service.

Easy to use, powerful, reliable and competitively priced CNC routers. With a wide range of CNC routers to choose from and excellent after-sales care, we can help your business achieve its manufacturing goals by allowing it to increase efficiency, reduce waste and in turn increase company profits. With the UK’s best range of affordable CNC router machines, a Mantech system is the perfect choice for customers, whatever the industry. Sign makers, Fabricators, woodworkers, campervan conversion specialists, education, plastics fabrication, aerospace, engineering, shop fitting experts, exhibition stand makers and so much more.

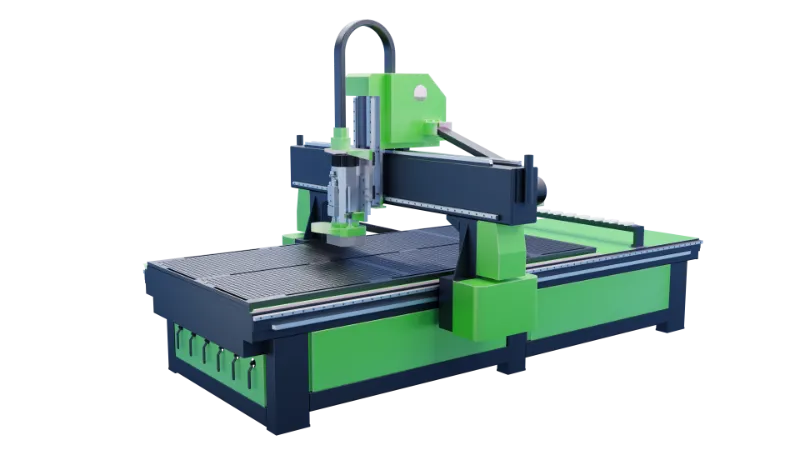

Spartan CNC Routers (Manual Series)

Full overview

The Spartan series is an industrial-grade, entry-level CNC router offering outstanding build quality and performance at an affordable price. This customer favourite delivers exceptional value with 6.0 kW spindles as standard on models 1325 and above.

Built with premium components, Spartan routers ensure robust construction and industry-standard reliability. A perfect choice for those seeking a cost-effective CNC router without compromising on quality.

Great for

Industries who use our Affordable Spartan CNC Routers:

Sign Making | Education | Shop Fitting | Makers | Vehicle Plylining | Custom Projects | Campervan Conversions | General Woodworking | Point of Sale | Personalised Gifts and Products | Exhibition Stand Builders and many

Bed sizes

Within the range, we have options such as our great space-saving 6090 entry-level CNC router with a full vacuum system included alongside our larger models that have bigger bed sizes. With popular bed sizes to cover most needs such as 8 x 4 ft and 10 x 5 ft alongside its reliable, high performance, this affordable CNC router machine really does hit the spot.

600 x 900 mm | 1300 x 2500 mm | 1500 x 3000 mm | 2000 x 3000 mm

Custom sizes are available upon request.

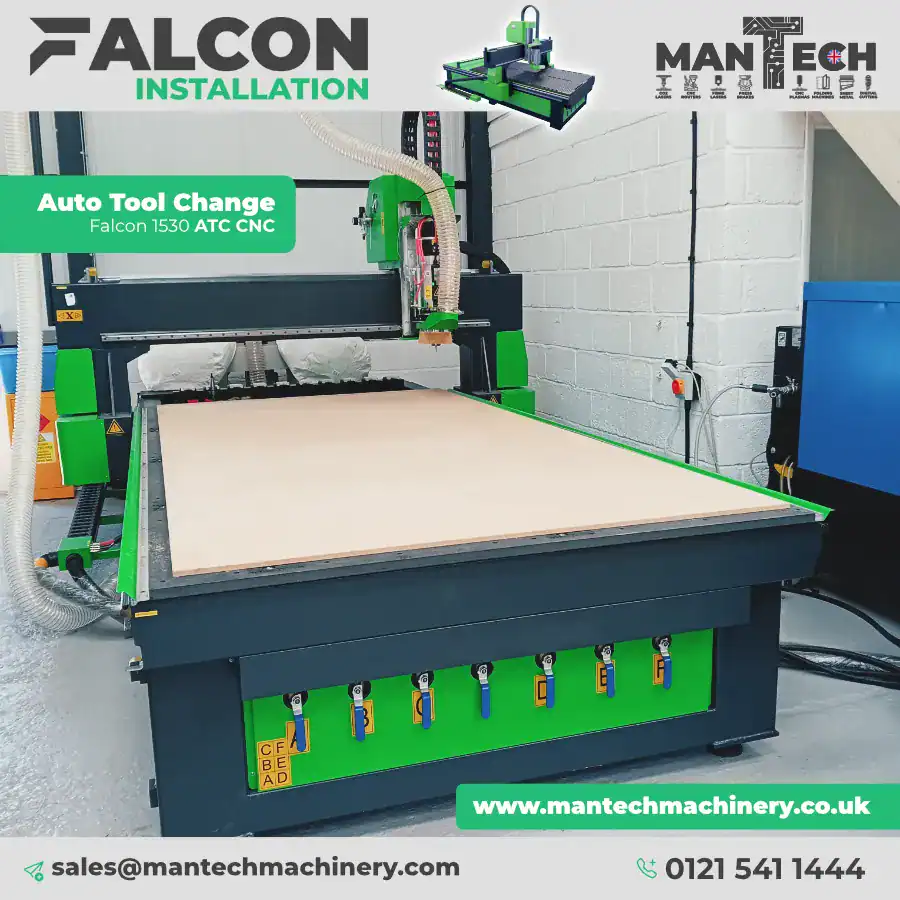

Falcon CNC Routers with ATC

The Falcon CNC router offers fast, reliable automatic tool-changing capabilities combined with excellent performance at an affordable price. Built with premium components, including a 9.0 kW air-cooled spindle and Delta servo motors, it ensures consistent reliability. A perfect choice for businesses needing efficiency and value.

Full overview

The Falcon is our most cost-effective ATC CNC router, combining reliability, power, and ease of use into a versatile machine. Designed for businesses seeking a high-value system, the Falcon features an economical automatic tool change setup, a 9.0 kW HQD air-cooled spindle, and a proven control system.

Built from industrial-grade high-tensile steel and equipped with Delta Servo Drives, this robust machine delivers exceptional performance. With a 2-year parts and labour warranty and outstanding post-sales support, the Falcon ATC CNC Router is an ideal choice for those looking for quality and affordability in one package.

Great for

Industries that use our Falcon ATC CNC Routers:

Sign Making | Education | Shop Fitting | Makers | Vehicle Plylining | Custom Projects | Campervan Conversions | General Woodworking | Point of Sale | Fabrication | CNC routing and Engraving Services | Architectural Design |

Bed sizes

Available in a range of bed sizes such as 8 x 4 ft, and 10 x 5 ft we also offer the Falcon ATC in bed sizes of 2000 x 3000 mm and 2000 x 4000 mm to cater for larger sheets of materials.

1300 x 1300 mm | 1300 x 2500 mm | 1500 x 3000 mm | 2000 x 3000 mm | 2000 x 4000 mm

Custom sizes are available upon request.

Apollo CNC Routers

(Manual Series)

Full overview

At the core of the Apollo M or ATC Router is its advanced automatic tool-change spindle system, eliminating the need for manual tool changes (ATC option required). Apollo ATC CNC Routers feature 7.5kW or 9.0 kW air-cooled spindles with speeds up to 24,000 rpm, paired with precision servo drives for unmatched accuracy.

Built to handle heavy workloads in demanding environments, the Apollo range is equipped with M-TECH motion control and includes a PC podium for seamless operation. Designed to enhance productivity and reduce manufacturing times, Apollo CNC Routers offer industrial-grade construction and exceptional performance. All models include a 2-year parts and labour warranty for peace of mind.

Great for

Industries that use our High-Performance Apollo Manual and ATC CNC Routers:

Sign Making | Education | Shop Fitting | Makers | Vehicle Plylining | Custom Projects | Campervan Conversions | General Woodworking | Point of Sale | Fabrication | CNC routing and Engraving Services | Architectural Design | Prototypying | Movie Set & Design | Universities & Colleges | Kitchen Fabrication | Custom Furniture | Aerospace Engineering | Cabinet Making | Industrial Designers

Bed sizes

Available in a range of bed sizes such as 8 x 4 ft, and 10 x 5 ft we also offer the Falcon ATC in bed sizes of 2000 x 3000 mm and 2000 x 4000 mm to cater for larger sheets of materials.

1300 x 1300 mm | 1300 x 2500 mm | 1500 x 3000 mm | 2000 x 3000 mm | 2000 x 4000 mm

Custom sizes are available upon request.

Apollo CNC Routers with ATC

Full overview

At the heart of the Apollo ATC Router is its advanced automatic tool-change spindle system, eliminating the need for manual tool changes. Each Apollo ATC CNC Router features a 9.0 kW air-cooled spindle capable of reaching speeds of 24,000 rpm, paired with precise servo drives for exceptional accuracy and consistency.

Designed to handle demanding workloads, the Apollo ATC is built with industrial-grade construction and M-TECH motion control, complemented by a PC podium for intuitive operation.

Known for reducing production times while enhancing efficiency, Apollo ATC CNC Routers deliver outstanding performance and reliability. All models include a 2-year parts and labour warranty for peace of mind.

Great for

Industries that use our High-Performance Apollo ATC CNC Routers:

Sign Making | Education | Shop Fitting | Makers | Vehicle Plylining | Custom Projects | Campervan Conversions | General Woodworking | Point of Sale | Fabrication | CNC routing and Engraving Services | Architectural Design | Prototypying | Movie Set & Design | Universities & Colleges | Kitchen Fabrication | Custom Furniture | Aerospace Engineering | Cabinet Making | Industrial Designers

Bed sizes

Available in a range of bed sizes such as 8 x 4 ft, and 10 x 5 ft we also offer the Falcon ATC in bed sizes of 2000 x 3000 mm and 2000 x 4000 mm to cater for larger sheets of materials.

1300 x 1300 mm | 1300 x 2500 mm | 1500 x 3000 mm | 2000 x 3000 mm | 2000 x 4000 mm

Custom sizes are available upon request.

Apollo 4 Axis CNC Routers

Full overview

The Apollo 4 Axis CNC Router is a state-of-the-art multi-axis machine, offering advanced features for unparalleled control and flexibility with machining angles from 0 to 180 degrees. With high-speed servo motors, fast transmission, and the renowned Syntec control system, this router ensures rapid and versatile productivity.

To enhance 4-axis operations, we include Alphacam software, one of the most comprehensive CAD/CAM solutions available.

For customers seeking a durable yet cost-effective 4-axis CNC Router, the Apollo delivers outstanding performance and key features. Backed by a 2-year parts and labour warranty, this machine offers complete peace of mind for your investment.

Great for

Industries that use our High-Performance Apollo 4 Axis CNC Routers:

Sign Making | Education | Shop Fitting | Makers | Vehicle Plylining | Custom Projects | Campervan Conversions | General Woodworking | Point of Sale | Fabrication | CNC routing and Engraving Services | Architectural Design |

Bed sizes

With standard bed sizes to cover most sheet sizes our Apollo 4-Axis CNC router can be purchased in the following sizes:

1300 x 2500 mm | 1500 x 3000 mm | 2000 x 3000 mm | 2000 x 4000 mm

Custom sizes are available upon request.

Apollo 5 Axis CNC Routers

Full overview

Discover the Apollo 5 Axis CNC Router—an advanced multi-axis machine designed to provide exceptional control and flexibility for a wide range of machining angles and complex geometries.

With high-speed servo motors, rapid transmission, and a user-friendly control system, the Apollo 5-axis CNC Router ensures efficient and versatile performance.

We also supply Alphacam software, a leading CAD/CAM solution essential for 5-axis operations. Contact our team for further details.

An excellent choice for customers seeking a durable and cost-effective 5-axis CNC Router, this system delivers outstanding performance with advanced features. Backed by a 2-year parts and labour warranty, it’s an investment you can trust.

Great for

Industries that use our High-Performance Apollo 5 Axis CNC Routers:

Aerospace Component Manufacturing | Automotive Industry Mold and Die Making | Medical | Architectural Design | Sculptures | Furniture and Design | ship Building | Energy Sector | Custom Tooling & Fixtures | Model Making

Bed sizes

Our Apollo 5-Axis CNC router can be purchased in the following sizes:

1600 x 2500 x 1000 mm as standard with custom sizes available.

Custom sizes are available upon request. (Please ask for details

Pendulum-Style Dual Bed CNC Routers

Discover the productivity-boosting capabilities of our Dual Bed CNC Routers, equipped with a gantry-mounted automatic tool change system. Load materials on one bed while the other operates, reducing downtime, improving throughput, and maximising profitability. These pendulum-style routers are ideal for businesses looking to enhance manufacturing efficiency and reduce customer lead times.

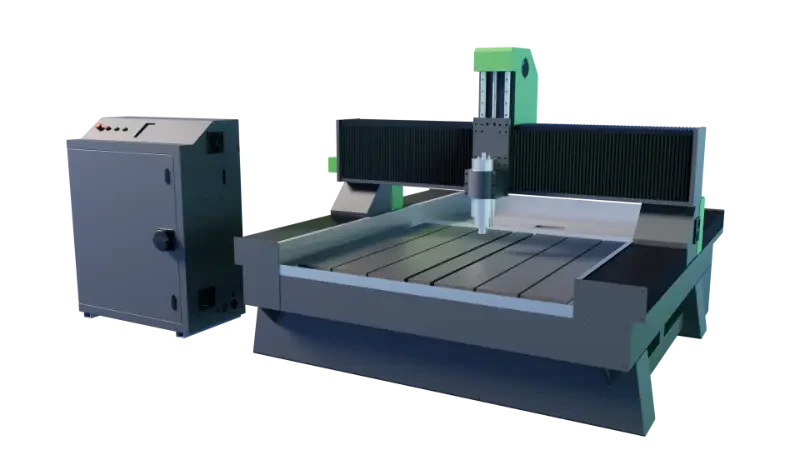

Stone-Tech CNC Routers

The Stone-Tech CNC Routers are purpose-built for precision cutting and engraving of stone and marble materials. With industrial-grade durability and a user-friendly design, these machines deliver exceptional performance for stone masons and architectural applications. Cost-effective and versatile, the Stone-Tech system enhances workflows with reliable and precise results.

CNC Router Tooling and Parts

Compare Our most popular Ranges

Most Affordable

Spartan CNCExtras: Specialist tooling, MDF/fine dust extraction filters.

Auto Tool Change

Falcon CNCExtras: Specialist tooling, MDF/fine dust extraction filters. Drill bank, oscillating knife system (factory order and runs on Syntec not DSP),

Professional CNC

Apollo CNCExtras: Specialist tooling, MDF/fine dust extraction filters. ATC upgrade.

0-180 degs of Flexibilty

Apollo 4 AxisExtras: Specialist tooling, MDF/fine dust extraction filters.

How to Choose the Ideal CNC Router

Selecting the perfect CNC Router involves considering your material requirements, production needs, and the size of your workspace.

Selecting the correct CNC router bed size is critical to ensuring your router meets your production needs. Start by assessing the materials and designs you plan to work on and determine the largest size you will need to accommodate. For smaller tasks, a 600 x 900 mm bed like those in our Spartan range may be sufficient.

If you require larger working areas for advanced applications, our Falcon and Apollo ranges offer sizes up to 2000 x 4000 mm, providing ample space for bigger projects. Additionally, custom bed sizes can be designed to meet specific requirements, offering maximum flexibility for your operations.

ATC systems allow programmed tool paths to be executed seamlessly, enabling the machine to automatically select, retrieve, and swap tools without manual intervention.

For operations requiring these capabilities, consider the Falcon ATC or Apollo ATC ranges, which are equipped with advanced tool-changing functions to significantly reduce production cycle times.

For businesses requiring advanced functionality, consider machines equipped with M-TECH CNC motion control or Syntec systems, perfect for dual bed, oscillating knife, drill bank, or 4-axis operations.

The Apollo range, including Apollo M and ATC versions, delivers exceptional performance. For side drilling and cutting, the Apollo 4 Axis ATC is a standout choice, featuring a 9kW air-cooled spindle capable of rotation for side processing. This model also includes pod and rail systems to elevate workpieces for added versatility.

The Apollo 5 Axis offers an extra axis, enabling advanced three-dimensional machining with complex geometries.

If maximum productivity is a priority, dual-bed CNC routers allow simultaneous loading and operation for seamless efficiency.

For stone cutting and engraving, the Stonetech CNC router, with its powerful spindle and constant flow cooling, is the ideal solution.

What Can You Process With a CNC Router

Additional Materials for CNC Router Processing

CNC Router Software Solutions

It enables 2D design creation with profile, pocket, drill, and inlay toolpaths, along with v-carving textures. Import and machine unlimited Vectric 3D clipart or individual model files effortlessly. The Pro version also offers unlimited job sizes, true shape nesting, and detailed job setup sheets, making it ideal for production settings. Training on VCarve Pro is included with every CNC router purchase to ensure seamless integration into your operations.

Your FAQs Answered

Understanding CNC Routers

A CNC Router (or computer numerical control router) can be used to process the tasks of other machinery in an all-in-one solution, for example:

Panel SawSpindle moulder Or a boring machine Instead of routing by hand, a CNC router uses tool paths that are controlled by the CNC router.

You can cut out both simple and complex shapes using designs that have been produced by software such as Vectric V Carve Pro, Cut2D, Aspire, Alphacam etc.

Our CNC routers come with Vectric V Carve as standard, with Alphacam as an option. A CNC router can produce extremely consistent, high-quality output, unlike more traditional hand-operated methods.

By using a CNC router over a jig router, you will also be able to produce one-offs just as effectively as producing identical repeat items. Automation and precision are two of the key draws when purchasing a CNC router machine.

Some of the benefits of using a CNC router include:

Reducing waste

Reduction in production times

Repeat, high-quality output

Versatile, a CNC uses different types of tooling, giving the user the ability to cut many different materials and allowing for multiple cut formats.

Using your CNC router, you can produce many different projects and items such as:

Interior & exterior decoration

Wood panels

Signboards and products

Instruments

Furniture

Worktops

Kitchen products such as cabinets, doors

3D engraving

Campervan conversions

Custom prototypes

Model production

Exterior furniture for playgrounds, parks and recreation

Vehicle ply lining and much more…

Our high-performance, industrial yet easy-to-use CNC routers are split across 8 different ranges:

Spartan | Falcon ATC | Apollo M | Apollo ATC | Apollo 4-Axis | Apollo 5-Axis | Stonetech | Dual Bed Systems

Industries That Benefit from CNC Routers

CNC routers are incredibly versatile, making them the preferred choice for businesses across a variety of industries. With a wide selection of tools and materials available, CNC routers simplify complex tasks, allowing you to focus on improving your manufacturing processes and growing your business.

Examples of Industries and Customers Using Our CNC Routers:

- Furniture manufacturers.

- General woodworking businesses.

- Staircase makers.

- Plastic fabricators.

- Aerospace and marine engineers.

- Bespoke woodcraft specialists.

- Van plyliners and vehicle conversion companies.

- Sign makers and exhibition stand manufacturers.

- Boat builders and custom guitar makers.

- Shadow board and toolbox manufacturers.

- Educational institutions, charities, and non-profits.

- Component engineering firms.

- Shop fitting contractors.

This list is far from exhaustive—CNC routers are used by countless other industries and businesses to enhance productivity and achieve precision in their projects.

More CNC Router Insights:

- CNC router business ideas.

- Choosing the best CNC router for your business

- Understanding the ROI when investing in a CNC Router.

- The benefits of using a CNC router for Campervan conversions

- Troubleshooting common CNC router issues: A quick reference guide

- Boost your manufacturing capabilities with a Mantech CNC Router

- Top 5 reasons to buy a CNC Router

- CNC router business ideas

Explore Mantech’s CNC Router Options

At our state-of-the-art 32,000-square-foot facility in Halesowen, West Midlands, we thoroughly test our CNC routers to ensure they meet the highest standards of quality and performance. Our mission is to provide affordable, high-quality CNC machinery supported by exceptional customer service.

Our standard CNC routers come equipped with essential features, including vacuum beds and pumps, efficient extraction systems, and high-performance spindles ranging from 6KW to 9.0KW Air-Cooled Electro Spindles.

Our team of industry experts is available to guide you in selecting the ideal CNC router for your specific needs. Each machine in our lineup is designed to handle diverse industrial applications with precision and reliability. Capable of cutting and engraving materials like plastics, acrylic, HDPE, wood, aluminium, brass, and other soft metals, our CNC routers come in standard sizes such as 8×4 ft, and 10×5 ft, as well as customised dimensions.

- Spartan CNC Routers: Easy-to-use machines with a standard 12-month warranty, ideal for first-time users.

- Falcon ATC: Features a dependable automatic tool change system with upgrade options like oscillating knives and drill bank units.

- Apollo M and Apollo ATC Routers: Equipped with our proprietary M-Tech CNC motion control system and backed by an industry-leading 2-year warranty.

Our customer feedback reflects our dedication to delivering high-quality, affordable CNC routers along with unmatched after-sales support. Whatever your application, our CNC routers provide the power and precision you need to enhance your operations.

Benefits of Using a CNC Router

A CNC router can help your business achieve its manufacturing goals by automating manual processes like cutting, profiling, drilling, and engraving.

Adopting CNC routing technology reduces labour-intensive tasks, saving on manufacturing costs, improving product quality, and minimising material waste. It also enables businesses to integrate their R&D efforts with product development, creating innovative products and services.

Our CNC machines are versatile, catering to various requirements, from standard 3-axis routing to more advanced 4-axis operations. We also provide custom CNC solutions, including multi-spindle systems, stone routing and engraving, and dual bed machines, ensuring a solution tailored to your specific needs.

Our team of experienced professionals is here to guide you in choosing the perfect CNC router for your business, maximising your productivity and efficiency.

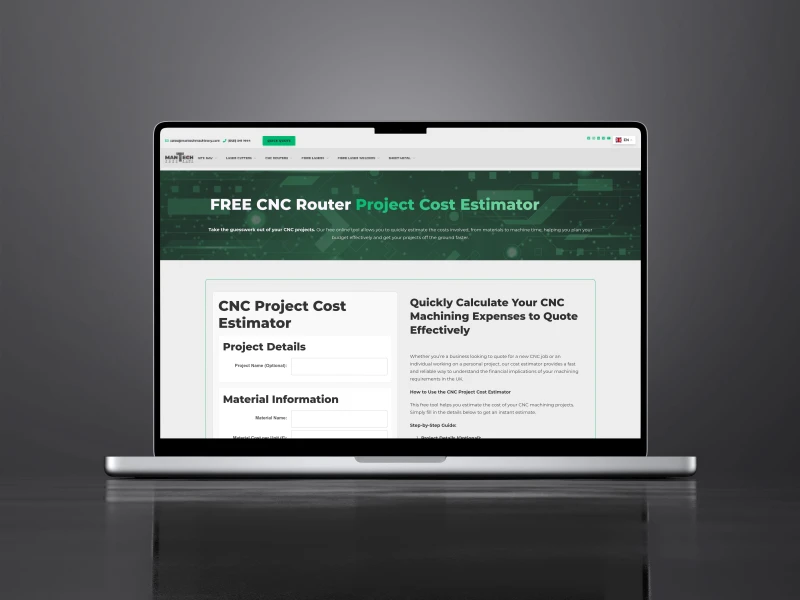

Get Access to our FREE CNC Job Costing Tool

Whether you’re a business looking to quote for a new CNC job or an individual working on a personal project, our cost estimator provides a fast and reliable way to understand the financial implications of your machining requirements in the UK.

Calculate now

Interesting CNC Router Market Fact!

CNC Router Market Application Breakdown (2020–2030)

The global CNC router market is evolving alongside trends in manufacturing, with metalworking representing 39.6% of application use in 2023 and expected to rise further by 2030. Growth in this segment is driven by demand for high-precision machining in non-ferrous metals.

Sources: Grand View Research · Global Growth Insights · Verified Market Reports

Keep up with the Latest

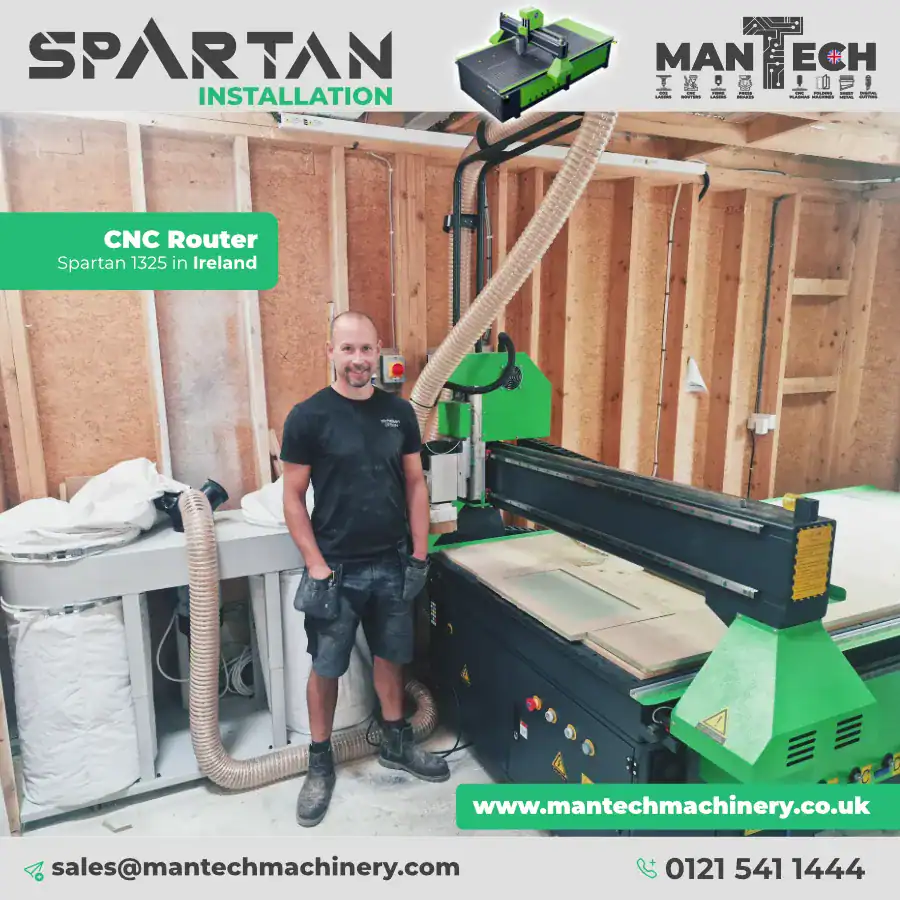

Apollo 1530 ATC CNC Router Installation in Ireland

Precision Delivered: Spartan 1325 Installed in Cork

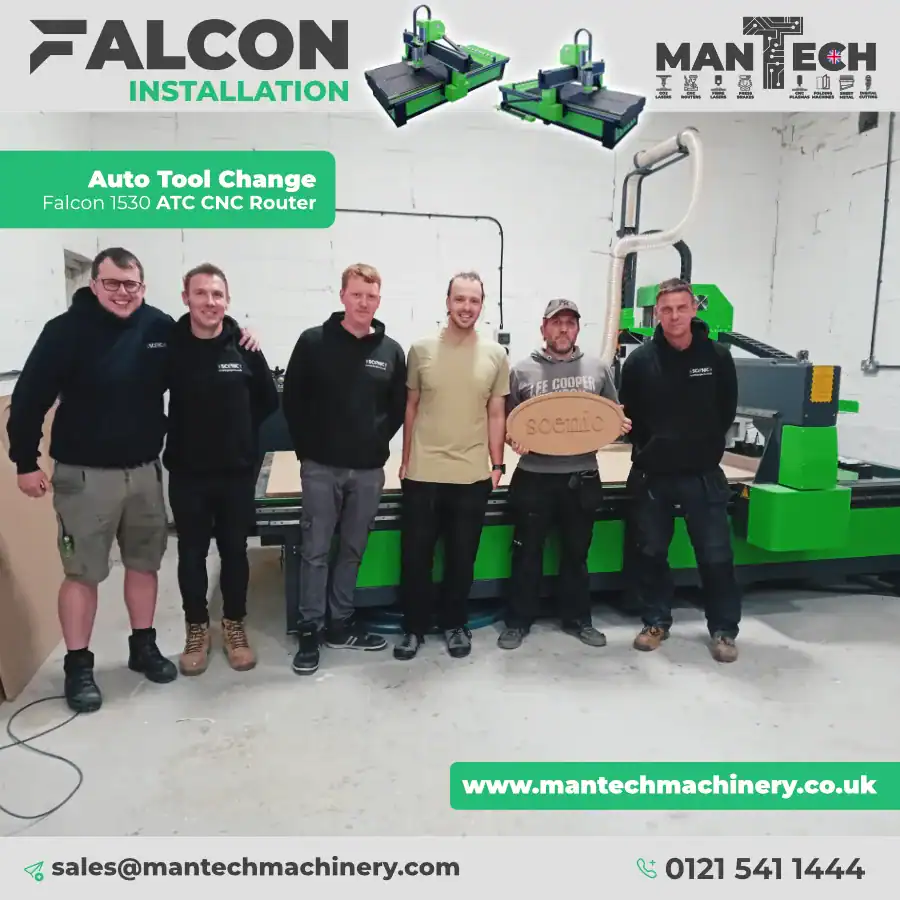

Falcon 1530 ATC CNC Router Installation in Warwickshire

Empowering Future Engineers at York College

🛠️ Falcon 1325 ATC CNC Router Installed in the UK – Speed Meets Precision!

Spartan 1530 CNC Router Installed – Built for Big Ambitions!

Spartan 1325 CNC Router Installed – Compact Power in Action

Enhancing UK Manufacturing: Falcon 1530 ATC CNC Router Installation