High-Power SF Fibre Laser Cutters with Power Options up to 30kW

Unmatched Fibre Laser Cutting Power

Flexible Cutting Table & Configuration Options

Precision & Consistency in High-Output Production

Full UK Warranty

Delivery Included

Installation Included

6-30kW Options

Exceptional Service

Unrivalled Precision & High-Power Fibre Lasers - SF Gen 4 Cutting Systems

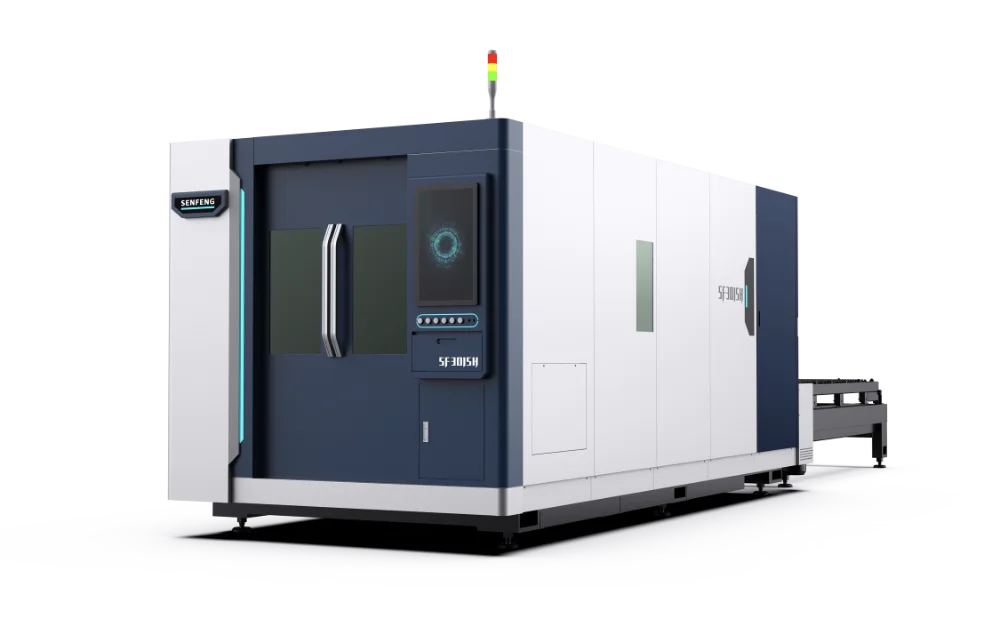

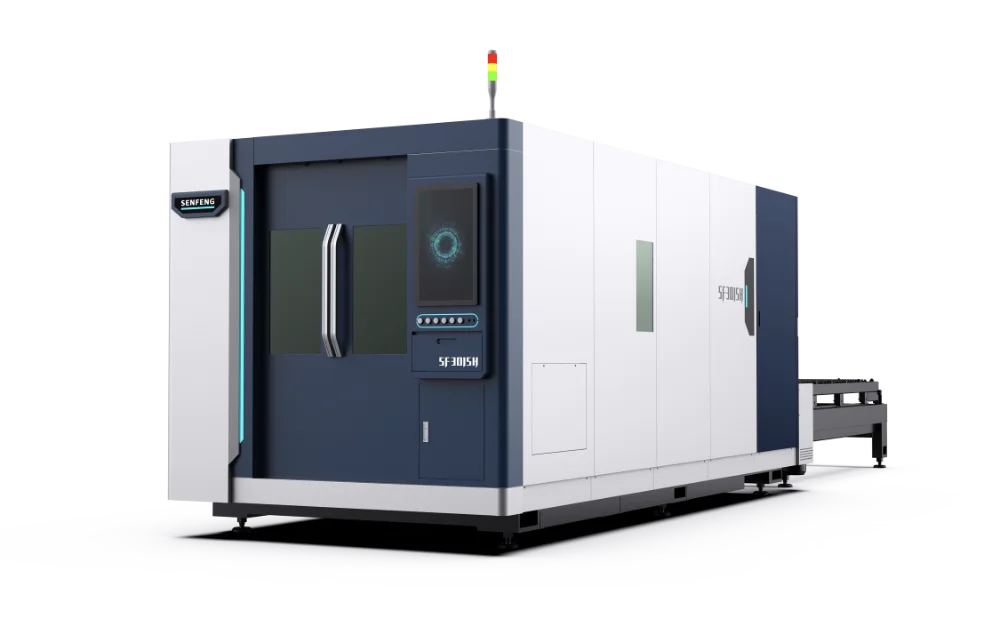

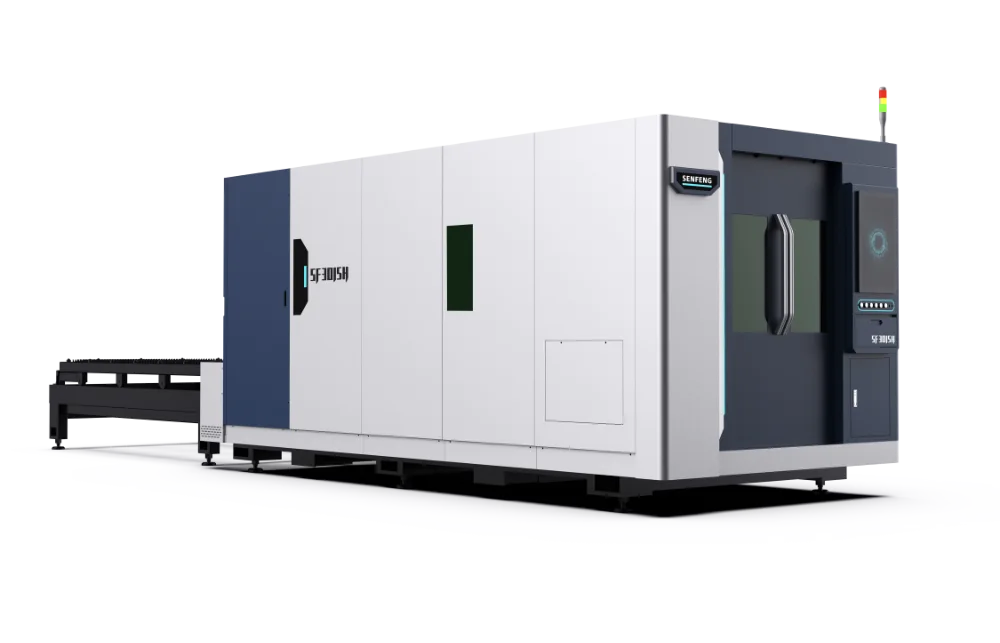

High-Performance SF H Gen 4 Fibre Lasers - Precision & Power for Demanding Applications

Unleash High-Powered Performance with the SF H Gen 4 Fibre Laser Series

Fully Featured

Incredibly Powerful

Dual Shuttle Exhange Tables

Overview and Features

| SF High Power Fibre Datasheet | Description |

|---|---|

| Cutting table sizes | 1500 x 3000 mm | 2000 x 4000 mm | 2500 x 6000 mm |

| Table type | Low contact cutting table |

| Shuttle Exchange Table | Yes - dual shuttle exchange tables included |

| Laser Power Options | 6kW | 8kW | 10kW | 12kW | 15kW | 20kW | 30kW options |

| Positioning Accuracy (X,Y axis) | ±0.05 mm |

| Repeat Positioning Accuracy (X,Y axis) | ±0.02 mm |

| Max Speed | 130 m/min |

| Max Acceleration | 1.0G |

| Safety Enclosure | Yes – full safety enclosure to protect your operators from any stray beams and to aid in the safe extraction of cutting vapour |

| Laser Cutting Head | Raytools - Autofocus |

| Servo Drives | High-accuracy servo-driven system |

| Drive System | Double Y axis ball screw transmission |

| Guide Rails | HIWIN guide rails |

| Ball Screw | TBI ball screw |

| Dual Channel Water Chiller | Yes - S&A CWFL Series (model is power dependant) |

| CNC Controller | Cypcut CNC control |

| Software Included | Yes - integrated CAD package for on-machine file creation/editing |

| Consumables | Yes - set of protective lens, focus lens, and nozzle pack supplied (additional available to purchase) |

| Power requirements | 3 Phase AC 380V 50HZ |

| Delivery and installation | Included (offloading and positioning are available upon request). Installation and training included |

| Chiller Dimensions | S&A Model to Suite |

| Length | 550 mm |

| Depth | 770 mm |

| Height | 1030 mm |

| Weight | Appx 95kg |

Why Choose The SF H Gen 4 Fibre Laser Range?

The SF H Gen 4 Fibre Laser Range is designed for industrial applications requiring superior cutting power, precision, and reliability. With laser power options from 6kW to 30kW, these high-performance systems handle thick and demanding materials effortlessly, making them the ideal solution for heavy-duty metal fabrication.

Equipped with auto-exchange shuttle tables, the SF H Gen 4 series enhances productivity by allowing continuous operation while minimising downtime. Whether you’re working in aerospace, automotive, or general fabrication, this cutting-edge technology ensures exceptional efficiency and precision. Mantech Machinery also provides full UK delivery, installation, and a comprehensive warranty, ensuring a seamless experience from purchase to operation.

Heavy Load – Thermal Isolated Bed Structure

The SF H Gen 4 Fibre Laser features a thermally isolated, heavy-duty hollow bed built from high-quality steel plates and pipes. Designed to prevent deformation and maintain structural integrity, the machine bed undergoes multiple treatments, including stress relief annealing and secondary ageing. These processes enhance stability, durability, and shock resistance, ensuring long-term performance.

Key Features:

- Heat-isolated hollow bed for consistent performance and temperature regulation.

- Double exchange platforms with deviation correction for enhanced precision.

- Aircraft-grade aluminium beam for a lightweight yet highly durable design.

- Graphite and copper protection for systems 8kW and above, optimised for high-power operations.

Aviation-Grade Gantry Beam Design

The SF H Gen 4 series incorporates aviation-grade high-strength aluminium alloy gantry beams, engineered for faster movement and increased efficiency. These beams feature a reinforced triangular structure for enhanced rigidity and impact resistance, making them ideal for high-speed cutting.

Precision Machining Process:

- Stage 1: Rough machining after annealing to eliminate internal stress.

- Stage 2: Fine machining following secondary vibration ageing treatment for maximum strength and stability.

This rigorous process ensures that the gantry beams maintain their durability and precision, even in the most demanding industrial environments.

Is Training and Delivery Included?

Yes, all of our Fibre Lasers include standard UK mainland delivery, as well as full operator training on both the machine and its software. This ensures you can confidently operate your system and maximise your productivity from day one.

| Metals |

|---|

| Stainless Steel |

| Mild and Carbon Steel |

| Copper |

| Brass |

| Aluminium |

| Titanium |

Fibre Laser Installations

Vector FL250 Fibre Laser Cutter Installation – West Yorkshire

New Vector FL250 Fibre Laser Installation – Wokingham (3kW Configuration)

SF3015 3kW Fibre Laser Installation – Wednesbury, West Midlands

Not sure which Fibre Laser model is right for you? Our team can help.