Ultra Heavy-Duty Tube Fibre Laser Cutters for Large-Scale Industrial Fabrication

Ultra Heavy-Duty Four-Chuck Tube Cutting System

Configurable Cutting Power from 4kW to 12kW

High-Speed Tube Cutting with Exceptional Accuracy

Full UK Warranty

Delivery Included

Installation Included

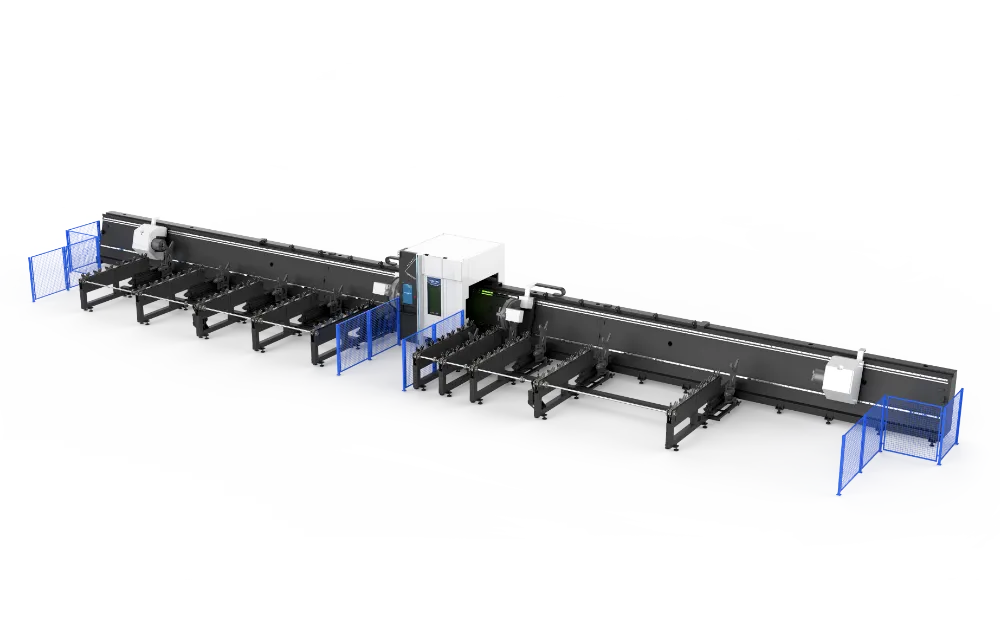

Heavy Duty Tube Cutter

520 mm Dia Tube (max)

SF12050HT Ultra Heavy-Duty Tube Laser - High Power Precision Cutting

SF 1250HT Ultra Heavy Tube Laser - Precision & Maximum Efficiency

Overview and Features

| SF 12050HT Tube Laser Datasheet | Description |

|---|---|

| Capacity | 12 meters x 500 mm chuck design |

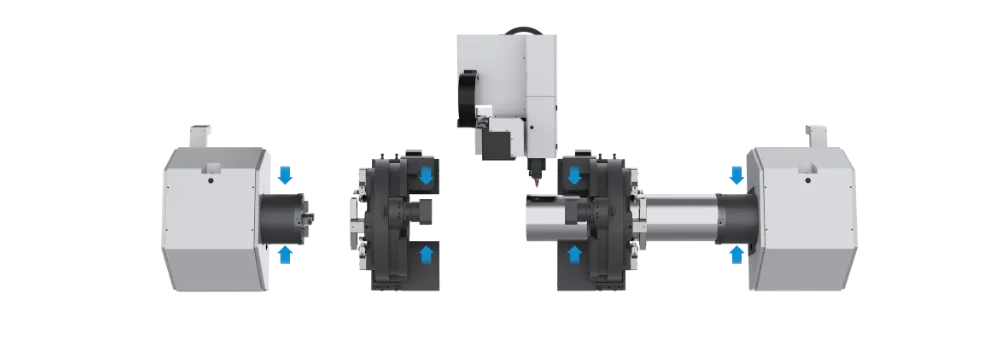

| Chuck System | Heavy duty x4 chuck system |

| Laser Power Options | 4kW | 6kW | 8kW | 12kW options |

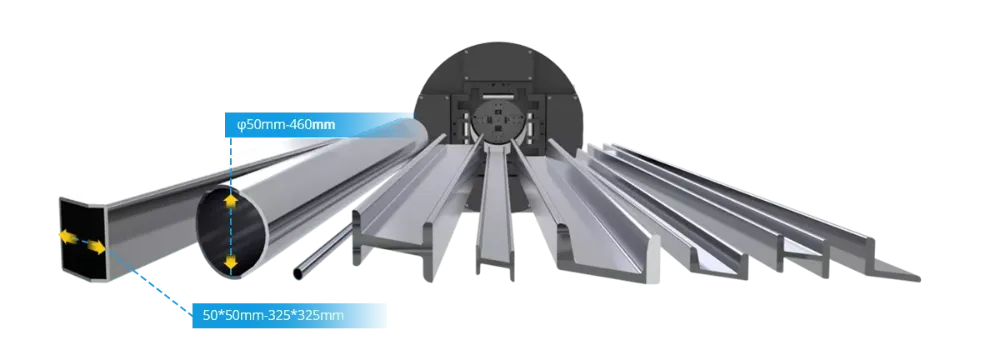

| Pipe Processing Range (Round Tube) | φ50-φ500mm |

| Min Clamping Wall Thickness (mm) | ≥ 3mm |

| Pipe Processing (Square Tube) | 50×50~500×500mm |

| Positioning Accuracy (X,Y axis) | ±0.01 mm |

| Repeat Positioning Accuracy (X,Y axis) | ±0.03 mm |

| Max Speed | 40 m/min |

| Max Chuck Speed | 40 r/min |

| Max Acceleration | 0.3G |

| Max Table Load | 2000kg |

| Safety Enclosure | Yes – safety enclosure to protect your operators from any stray beams and to aid in the safe extraction of cutting vapour. Safety fencing options. |

| Laser Cutting Head | Raytools - Autofocus |

| Servo Drives | High-accuracy servo-driven system |

| Dual Channel Water Chiller | Yes - S&A CWFL Series (model is power dependant) |

| CNC Controller | Cypcut/Cyptube |

| Software Included | Cyptube/Tubest 3D Nesting |

| Consumables | Yes - set of protective lens, focus lens, and nozzle pack supplied (additional available to purchase) |

| Power requirements | 3 Phase AC 380V 50HZ |

| Delivery and installation | Included (offloading and positioning are available upon request). Installation and training included |

| Chiller Dimensions | S&A Model to Suite |

| Length | 550 mm |

| Depth | 770 mm |

| Height | 1030 mm |

| Weight | Appx 95kg |

Why Choose The SF 12050HT Tube Fibre Laser Range?

The SF 12050HT Tube Fibre Laser Cutter is engineered for heavy-duty tube and profile cutting, providing unrivalled precision and efficiency for industrial applications. Capable of processing tubes up to 12 meters in length and diameters of up to 500mm, this machine is designed for large-scale manufacturing, structural engineering, and fabrication industries.

High-Powered Performance for Heavy-Duty Applications

With laser power options ranging from 4kW to 12kW, the SF 12050HT handles a variety of materials, including stainless steel, carbon steel, and titanium alloys, making it highly versatile for multiple industries.

Advanced Four-Chuck System for Precision Cutting

The X4 Chuck Holding System enhances tube stability during processing, ensuring precise, accurate cuts even for complex geometries and thicker materials. The system’s reverse cutting capability allows for full-length tube processing, maximising material usage while reducing waste.

Optimised Efficiency with CNC Bus Control & Tubest 3D Nesting Software

The integrated CNC bus control system and Tubest 3D nesting software streamline workflows, optimise cutting paths, and significantly reduce material waste, improving overall production efficiency.

Stable & Durable Side-Attached Bed Design

The SF 12050HT features a reinforced side-attached bed, improving structural stability, load-bearing capacity, and shock resistance for consistent cutting accuracy in heavy-duty environments.

Fully Enclosed Design for Maximum Operator Safety

Designed with safety in mind, the SF 12050HT Tube Laser features a fully enclosed cutting area, reducing exposure to laser radiation and airborne particulates, ensuring a cleaner and safer work environment.

Enhanced Material Handling & Waste Reduction

The innovative four-chuck delivery system enables automated positioning and rotation, enhancing cutting precision while reducing material waste, making it an ideal solution for high-volume production.

Comprehensive Training & UK Delivery Included

All SF Fibre Laser systems include UK mainland delivery and full operator training, ensuring you and your team are fully equipped to maximise productivity from day one.

Invest in High-Performance Tube Laser Cutting

Whether you’re in construction, automotive, aerospace, or industrial fabrication, the SF 12050HT Tube Fibre Laser Cutter delivers exceptional precision, productivity, and reliability, making it a must-have for large-scale operations.

| Metals |

|---|

| Stainless Steel |

| Mild and Carbon Steel |

| Copper |

| Brass |

| Aluminium |

| Titanium |

Fibre Laser Installations

Vector FL250 Fibre Laser Cutter Installation – West Yorkshire

New Vector FL250 Fibre Laser Installation – Wokingham (3kW Configuration)

SF3015 3kW Fibre Laser Installation – Wednesbury, West Midlands

Not sure which Fibre Laser model is right for you? Our team can help.