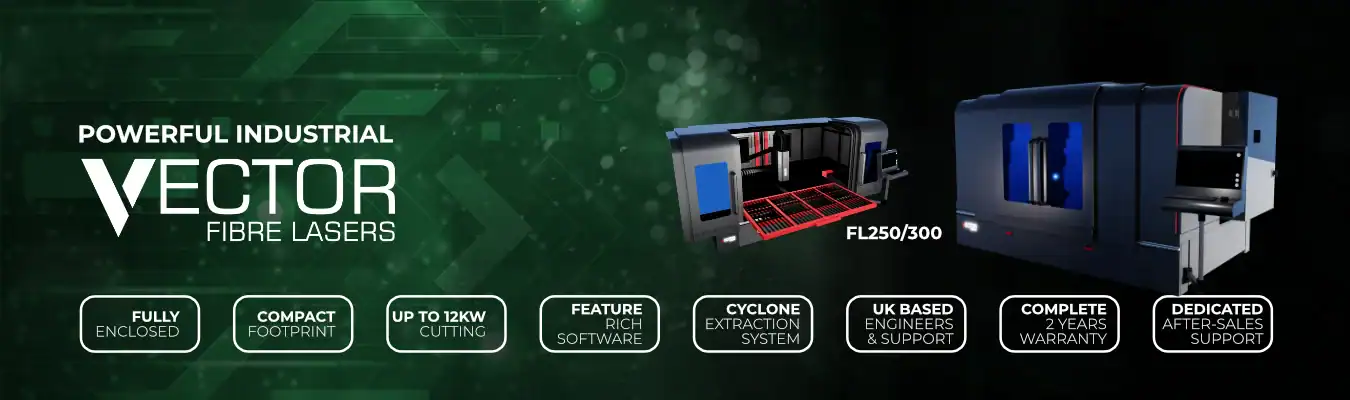

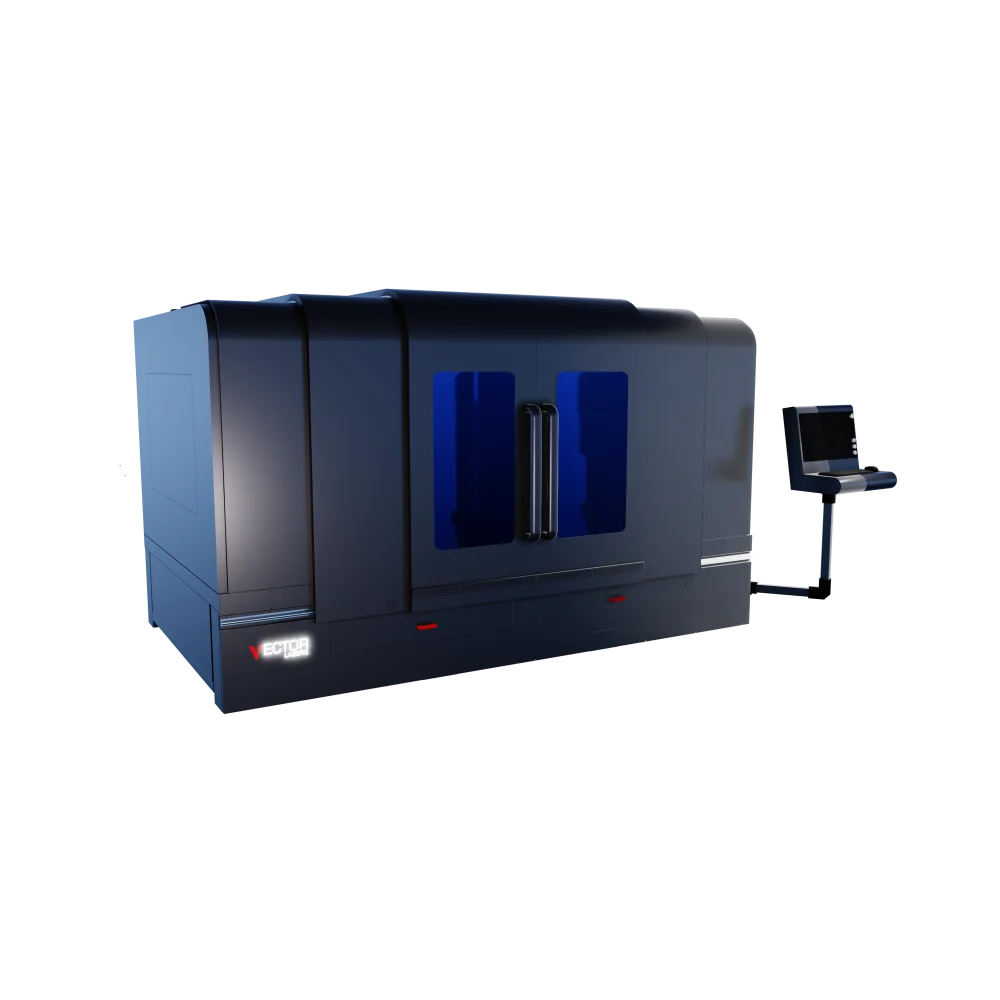

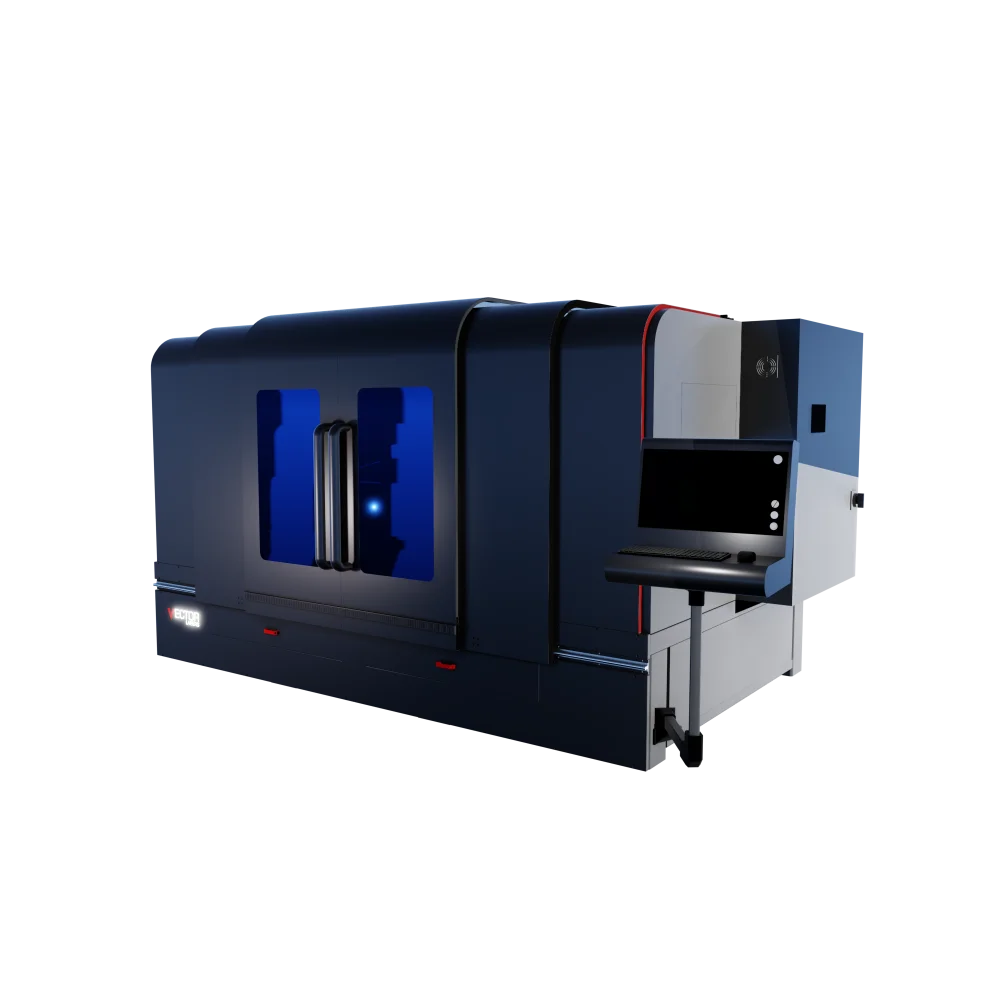

Vector FL250 & FL300 Fibre Lasers. High Performance Metal Cutting Up to 12kW

Optimised Cutting Flexibility with Two Table Size Options

High-Performance UK-Designed Fibre Laser Systems

Exceptional Cutting Power for Heavy-Duty Applications

Full UK Warranty

Delivery Included

Installation Included

Powerful Cutting Options

Exceptional Service

Unmatched Power and Precision. The Vector FL250 & 300 Fibre Laser Series

Comprehensive Features & Performance of the Vector FL250 and 300 Fibre Lasers

Revolutionise Your Manufacturing Process with High Performance Fibre Lasers

For Industry

Powerful

Reliable

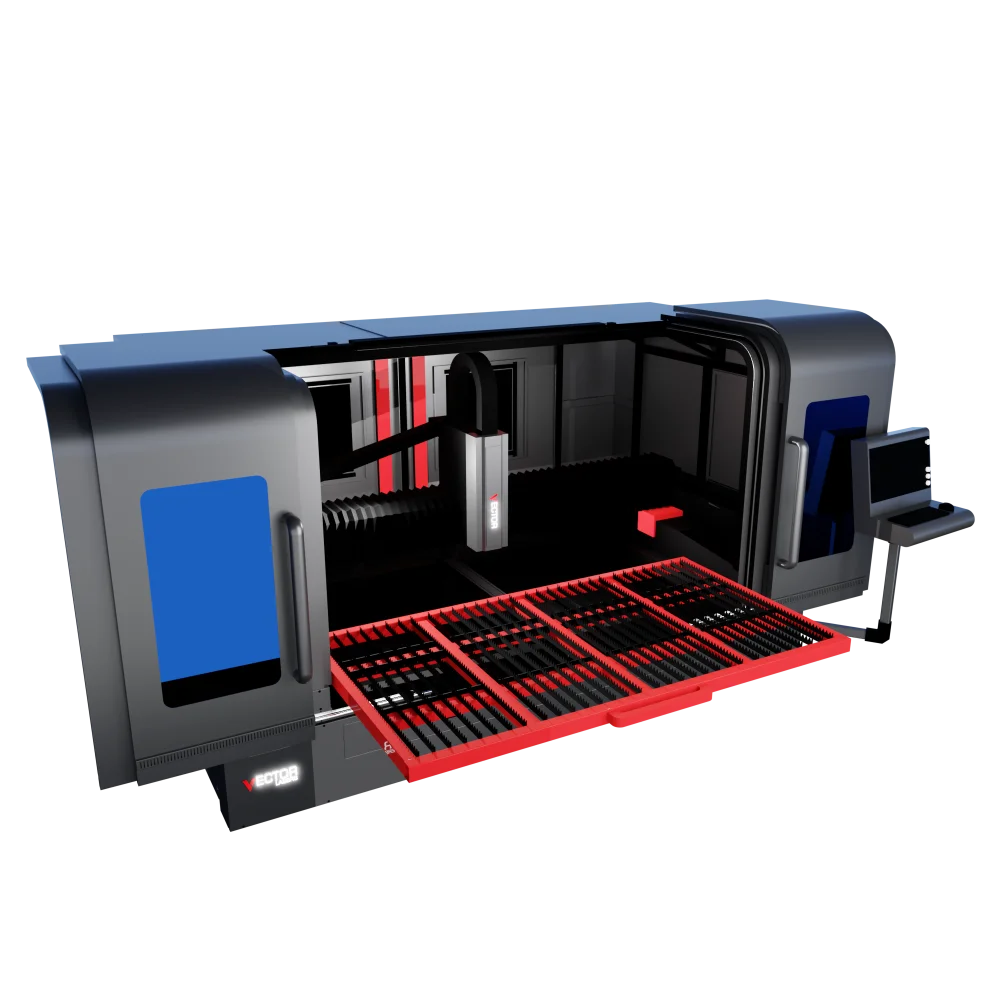

Overview and Features

| Vector FL250-300 Datasheet | description |

|---|---|

| Cutting table size | Options of either a 1260 x 2510 mm (FL250) or 1500 x 3000 mm (FL300) cutting area |

| Table type | Low contact cutting table |

| Safety Enclosure | Yes – full safety enclosure to protect your operators from any stray beams and to aid in the safe extraction of cutting vapour |

| Laser Power Options | 1.5kW / 2kW / 3kW / 4kW / 6kW / 12Kw options (please note the 12kW system comes with a motorised bed) |

| Laser Cutting Head | Raytools - Autofocus |

| Servo Drives | High-accuracy servo-driven system |

| Drive System | Double Y axis ball screw transmission |

| Guide Rails | HIWIN guide rails |

| Ball Screw | TBI ball screw |

| Dual Channel Water Chiller | Yes - S&A CWFL Series (model is power dependant) |

| CNC Controller | Cypcut laser cutting control system |

| Software Included | Yes - integrated CAD package for on-machine file creation/editing |

| Consumables | Yes - set of protective lens, focus lens, and nozzle pack supplied (additional available to purchase) |

| Power requirements | 3 Phase AC 380V 50HZ |

| Delivery and installation | Included (offloading and positioning are available upon request). Installation and training included |

| Machine Dimensions | Vector FL250 |

| Length | 3870 mm (with doors open 4650 mm) |

| Depth | 2575 mm |

| Height | 2331 mm |

| Weight | Appx 2995kg |

| Machine Dimensions | Vector FL300 |

| Length | 4850 mm (5600 mm with doors open) |

| Depth | 2995 mm |

| Height | 2331 mm. |

| Weight | Appx 3600kg |

| Chiller Dimensions | Power source dependant |

Why Choose The Vector FL250 & 300 Fibre Laser Range?

The Vector FL250 and FL300 Fibre Laser Cutters are engineered to meet the growing demands of modern fabrication and precision metal cutting. Designed with flexibility in mind, these machines feature spacious cutting tables—the FL250 offers a 1260 x 2510 mm bed, while the FL300 provides a 1500 x 3000 mm cutting area. This ensures compatibility with a variety of sheet sizes, making them ideal for high-production environments and large-scale manufacturing.

High-Powered Performance for Industrial Applications

With powerful laser options ranging from 1.5kW to 12kW, the FL250 and FL300 can effortlessly cut through mild steel, stainless steel, aluminium, brass, and copper, ensuring clean, precise edges with minimal material waste. Whether you’re handling high-volume production runs or intricate custom fabrications, these fibre laser cutters deliver unmatched accuracy, speed, and energy-efficient operation.

Advanced Automation & User-Friendly Operation

Equipped with the intuitive Cypcut control system, the FL250 and FL300 simplify workflow automation and minimise programming time, allowing operators of all skill levels to achieve consistent, high-quality results. The system supports DXF file processing, nesting optimisation, and advanced cutting path management, improving efficiency and reducing setup times.

Fully Enclosed Design for Maximum Safety

The FL250 and FL300 feature a fully enclosed safety housing with CE-rated laser protection viewing panels, safeguarding operators from laser exposure and metal particulates. Integrated fume extraction systems efficiently remove cutting vapours, ensuring a cleaner and safer working environment while complying with industry safety standards.

Cost-Effective & Energy Efficient

Unlike traditional metal-cutting methods, fibre laser technology significantly reduces energy consumption and maintenance costs, leading to long-term savings for businesses. With enhanced cutting precision, minimal waste, and reduced operational costs, the FL250 and FL300 offer a high return on investment for businesses looking to scale their manufacturing capabilities.

Is Training and Delivery Included?

Yes! All of our Fibre Laser Cutters include UK mainland delivery and comprehensive operator training. Our expert engineers will guide you through machine installation, software operation, and best practices, ensuring you have the confidence to start production immediately.

| Metals |

|---|

| Stainless Steel |

| Mild and Carbon Steel |

| Copper |

| Brass |

| Aluminium |

| Titanium |

Important Notice: This machine selector serves as a guideline to help you identify a suitable Vector Fibre Laser model. However, for a precise recommendation tailored to your specific application, material variations, production requirements, and any bespoke needs, we strongly recommend consulting with one of our experienced sales engineers. Their expertise ensures you select the optimal machine configuration for your needs.

Choose the right Vector Laser

Select material, enter thickness and sheet size to get a machine recommendation.

Request a Quick Quotation

Fibre Laser Installations - Latest

SF3015 3kW Fibre Laser Installation – Wednesbury, West Midlands

Vector FL250 Fibre Laser Installation for Imperial Locks, Willenhall

New Fibre Laser Installation – Shefford

New Fibre Laser Installation – Huddersfield University

New Fibre Laser Installation – Leicestershire

3kW Vector FL90 Fibre Laser Cutter Installation in Tarleton

Installation of a Vector FL250 Fibre Laser Cutter at Skilled Engineering