The UK's Leading Affordable Metal Guillotine Shear Experts.

Intuitive Control Systems

Heavy-Duty Construction

Multi-Industry Versatility

Precision Cutting Performance

Wide Range of Sizes & Capacities

Superior Cutting Quality

12 Months UK Warranty

Commissioning

Range of Options

Robust Construction

Easy to Operate

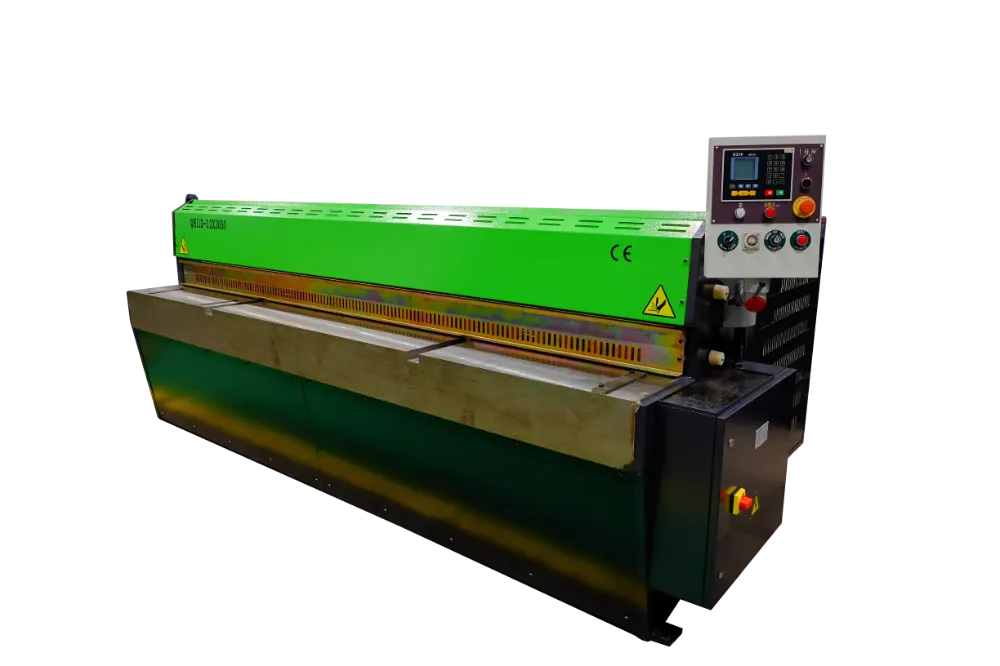

High Precision Mechanical Guillotine Shears - Reliable & Efficient Metal Cutting

Datasheet DownloadOur Mechanical Guillotine Shears are designed for precision, durability, and ease of operation, making them an essential solution for metal fabrication workshops. Available in four standard cutting sizes—1270 x 3.2 mm, 2000 x 3.2 mm, 2550 x 3.2 mm, and 3050 x 3.2 mm—these machines provide the versatility needed to handle various cutting applications with accuracy and efficiency.

Advanced Control & Optimised Productivity

Equipped with the powerful E21S CNC Control System, our mechanical guillotines offer enhanced automation and ease of use. Key features include:

✔ “Go To” Positioning for quick, repeatable cuts

✔ Programmable Multi-Step Sequences for streamlined workflows

✔ Stock Counter to track production output

✔ One-Side Positioning & Retract Functionality for precision cutting

Robust Design & Operator Convenience

- 1000 mm Squaring Arm with an integrated rule and flip-up stops for accurate material positioning

- 1000 mm Front Support Arms for improved material handling

- Heavy-Duty All-Steel Construction ensuring long-lasting durability and performance

- High-Quality Cutting Blades for clean and precise edge finishes

- Enhanced Safety & Reliable Performance

Our mechanical guillotine shears are powered by a 400V/3PH/50Hz electrical system, providing stable operation for continuous use. Each unit comes with:

✔ Optoelectrical Rear Guards for operator protection

✔ Electric Footswitch Control for hands-free operation and enhanced safety

✔ Comprehensive User Manual for easy setup and efficient use

Ideal for metal fabrication shops, industrial workshops, and manufacturing facilities, our Mechanical Guillotine Shears deliver precision cutting with outstanding efficiency. Whether working with mild steel, stainless steel, or aluminium, these machines ensure exceptional cutting accuracy and smooth operation for high-volume production.

Precision Hydraulic Guillotine Shears - High Performance Metal Cutting

Datasheet DownloadEnhance your metal-cutting efficiency with our Hydraulic Guillotine Shears, engineered for precision, power, and reliability. Available in sizes ranging from 2000 x 4 mm to 3200 x 6 mm, with custom dimensions available upon request, these shears offer exceptional versatility for industrial and fabrication applications.

Advanced Hydraulic Cutting for Maximum Efficiency

Our hydraulic guillotines are designed for smooth and precise cutting with:

✔ Fixed Cutting Angle for consistent accuracy across all materials

✔ Single-Handle Blade Clearance Adjustment for quick and precise setting changes

✔ Tiltable Front Finger Guard ensuring maximum operator safety

✔ Hydraulic & Electrical Overload Protection for long-term reliability

Intelligent CNC Control for Seamless Operation

Powered by the E21S CNC Control System, our hydraulic guillotines provide an intuitive, programmable interface with:

✔ 40 Program Storage Capacity with up to 25 programmable steps per program

✔ Precision Cutting Sequences for streamlined workflows

✔ Fast Material Positioning & Automatic Adjustments

Enhanced Safety & Operator Convenience

Built with durability and user-friendly operation in mind, each unit is equipped with:

✔ Optoelectrical Rear Guards for secure operation

✔ Electric Footswitch Control for hands-free cutting precision

✔ Comprehensive Guarding System for added workplace safety

✔ Heavy-Duty All-Steel Construction ensuring durability under high workloads

Operating on a 400V/3PH/50Hz power supply, our Hydraulic Guillotine Shears are the ideal choice for businesses seeking exceptional cutting precision, efficiency, and safety. Whether cutting mild steel, stainless steel, or aluminium, these machines provide clean, accurate cuts with minimal waste, making them an essential investment for high-performance metal fabrication.

Guillotine Standard Standard Features and Options

| Mechanical Guillotines | ||||||

|---|---|---|---|---|---|---|

| 1270 x 3.2 mm | 2000 x 3.2 mm | 2550 x 3.2 mm | 3050 x 3.2 mm | |||

| #colspan# | ||||||

| Standard Features | ||||||

| #colspan# | ||||||

| Squaring Arms | 1000 mm squaring arms with rule and flip-stops | |||||

| Support Arms | 1000 mm support arms | |||||

| Safety | ||||||

| Control System | E21S Control (go To) / Programmable steps/ Stock Counter/ One side positioning / Retract facility | |||||

| Footswitch | Electric footswitch operation | |||||

| Safety | Side fences, top fences and optoelectrical guards | |||||

| Electrical Supply | 400V/3PH/50hz | |||||

| Hydraulic Guillotines | ||||||||

|---|---|---|---|---|---|---|---|---|

| 2000 x 4 mm or 6 mm | 2500 x 6, 8, 10 or 12 mm | 2550 x 3.2 mm | 2550 x 3.2 mm | 3200 x 6 mm | ||||

| Standard Features | ||||||||

| Front Finger Guard | Tiltable | |||||||

| Blade Clearance Adjustment | Rapid and precise blade clearance adjustment by single handle on the side frame | |||||||

| Safety | ||||||||

| Control System | E21S Control: Programmable multiple steps can save up to 40 Programs 25 steps per program | One Key backup/restore facility | Holding, decompression time settings | Stock Counter | One side positioning Retract facility | |||||||

| Cutting Angle | Fixed | |||||||

| Footswitch | Electric footswitch operation | |||||||

| Safety | Side fences, top fences and optoelectrical guards | |||||||

| Overload Protection | Hydraulic and Electrical overload protection | |||||||

| Electrical Supply | 400V/3PH/50hz | |||||||