Metal & Non-Metal CO₂ Laser Cutting and Engraving Systems

Multi-Purpose Material Capability

Designed for Mixed-Material Workflows

UK Installation, Training & Support

Full UK Warranty

Delivery Included

Installation Included

Cuts Acrylic and Metal

Exceptional Service

M-CUT Laser Cutting and Engraving Machines

About Lasertech M-CUT CO2 Laser Cutters

Compare Our CO₂ Laser Cutting Machine Range

Desktop CO₂ | Pro Series CO₂ | Large Format CO₂ | Multi-Material CO₂ | |

Tytpical Use | Entry-level routing | Production routing | Industrial production | Multi-angle machining |

Primary Materials | Non-metals (acrylic, wood, plastics) | Non-metals, thicker materials | Non-metals, oversized sheets | Non-metals + selected thin metals |

Bed Size Range | Compact work areas | Medium to large work areas | Oversized / open-bed formats | Medium to large formats |

Power Options | Lower to mid power CO₂ tubes | Mid to high power CO₂ tubes | High power CO₂ tubes | CO₂ tube with auxiliary gas |

Production Suitability | Low-volume / prototyping | Medium-volume production | High-volume / large parts | Mixed-use production |

Installation and Support | UK & Ireland installation, training and ongoing support | |||

Ideal Use Case | Entry-level and space-limited environments | Most popular all-round solution | Large-scale cutting & engraving | Added versatility without fibre laser investment |

Product Link | ||||

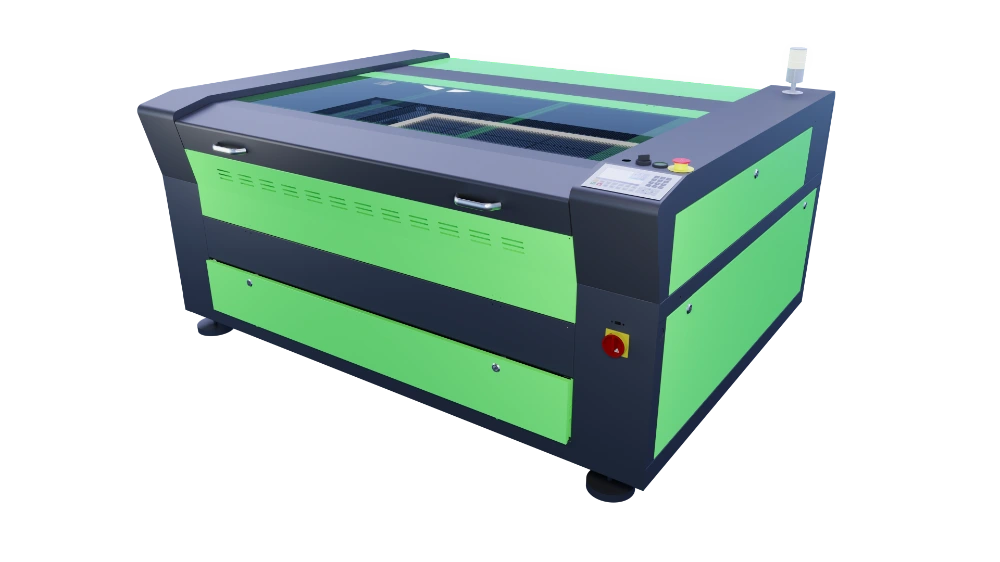

Powerful and Adpatable Laser Cutters!

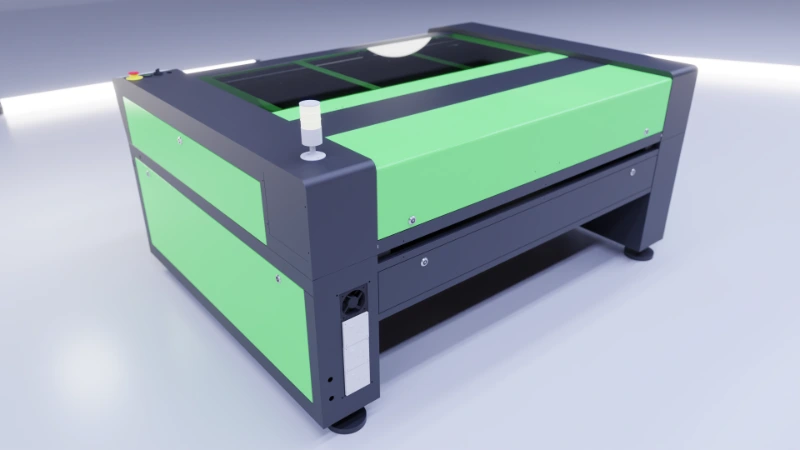

Rear view

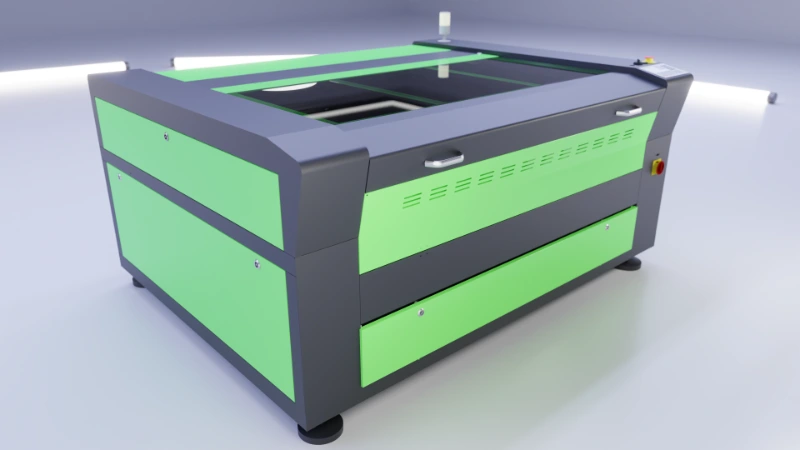

Side View

Top View

Overview and Features

| Lasertech MCUT Datasheet | description |

|---|---|

| Easy Control | Control your MCUT Laser Cutter with ease using the supplied software, Import files via USB Stick and edit on the fly. |

| Software Included | With all M-CUT lasers we supply Lightburn CAD/CAM software, easy to use and with an excellent array of valuable features. To use the metal cutting aspect you must still use RDworks for this to function (included). |

| RECI Laser Tubes | 150W Standard on all M-CUT lasers are the renowned RECI laser tubes. Perfect for cutting thicker materials (and when cutting thin metals with the oxygen assistive gas function). |

| Motorised Z Adjustment | This allows you to process thicker items in your laser cutter. |

| Low Contact Cutting Table | Used to create a low contact support base for your materials. Easily removed for cleaning procedures. |

| Cutting Size | 1300 x 900 mm (closest to A0). Suiting most user needs and applications. |

| Chiller System | All of our laser cutters come supplied with a suitable S&A chiller with upgrades available. |

| Air Assist | The pro laser cutting and engraving system comes with integrated air assist enhancing the output by removing debris from the cutting and engraving area. |

| Standard Extraction | Our Lasertech CO2 Laser Cutters come with vent-to-atmosphere extraction systems, however, we also supply both Purex and BOFA air filtration units should you prefer to upgrade. |

| Safety Eyeware | We supply a set of safety glasses with all of our machines. |

| Installation & Training | Our installation team carries out installation and safety training, giving you the confidence to use the machine before they leave. |

| Aftersales | After-sales service is UK based and available to all of our customers if needed. Lifetime technical support via email and telephone. |

| Warranty | All Lasertech laser cutters come with our excellent 12-month parts & labour warranty (does not include consumables). |

Why Choose The Lasertech MCUT Range?

Its generous 1300 x 900 mm cutting area supports projects of all sizes, making it ideal for industries like sign-making, education, fabrication, and custom manufacturing. Intuitive software streamlines the design and cutting process, boosting efficiency and accuracy.

The M-CUT also offers features such as motorised Z-height adjustment for thicker materials, integrated air assist to clear debris, and a low-contact blade bed for seamless material handling. A genuine S&A chiller is included to maintain optimal temperatures during operation.

Supported by expert installation, safety training, and lifetime technical assistance from Mantech Ireland, the M-CUT is a dependable and budget-friendly choice for a wide range of cutting and engraving applications.

Do You Supply Software?

Yes, all Pro range laser cutters are equipped with advanced software called LightBurn. You can try it for free by downloading the trial version from their website. LightBurn offers a superior experience compared to RDWorks, which is commonly used with RUIDA-based control systems.

Is Training and Delivery Included?

All of our laser cutters include our standard UK mainland delivery and include full training on your new machine and how to operate the software to send jobs to be cut or engraved.

What About Fume Extraction & Filtration Upgrades?

Yes, our Pro Lasers come equipped with standard vent-to-atmosphere extraction, which is suitable for most customers. However, fume extraction is a critical aspect of laser cutter operation, and requirements can vary. For enhanced performance, we offer optional upgrades like Purex and BOFA filtration systems, ideal for use in homes, offices, or educational settings. Contact us for more information.

Can I Buy Acrylic Sheets From You?

You can purchase your materials from a wide range of suppliers, in fact, we also supply a selection of acrylic materials that are suitable for laser cutting over at our parts and consumables site www.mantechparts.co.uk

| Material | Engrave | Cut |

|---|---|---|

| Natural wood | Yes | Yes |

| Acrylic | Yes | Yes |

| Glass | Yes | No |

| Engraving laminate | Yes | Yes |

| Bamboo | Yes | Yes |

| MDF | Yes | Yes |

| Leather | Yes | Yes |

| Cloth | Yes | Yes |

| Marble | Yes | No |

| Matte boards | Yes | Yes |

| Stone | Yes | No |

| Paper | Yes | Yes |

| Mylar | Yes | Yes |

| Press Board | Yes | Yes |

| Rubber | Yes | Yes |

| Laser Ply | Yes | Yes |

| Anodised or painted metal | Yes | No |

| Other plastics | Yes | Yes |

| Ceramics | Yes | No |

| Mild Steel | Yes | Yes 2 mm (max) |

| Stainless Steel | Yes | Yes 1 mm (max) |

Our Laser Cutters are Great For

Request a Quick Quotation

Keep up with the Latest

View All CO2 Laser Installations