The UK's Leading Affordable Press Brake Experts.

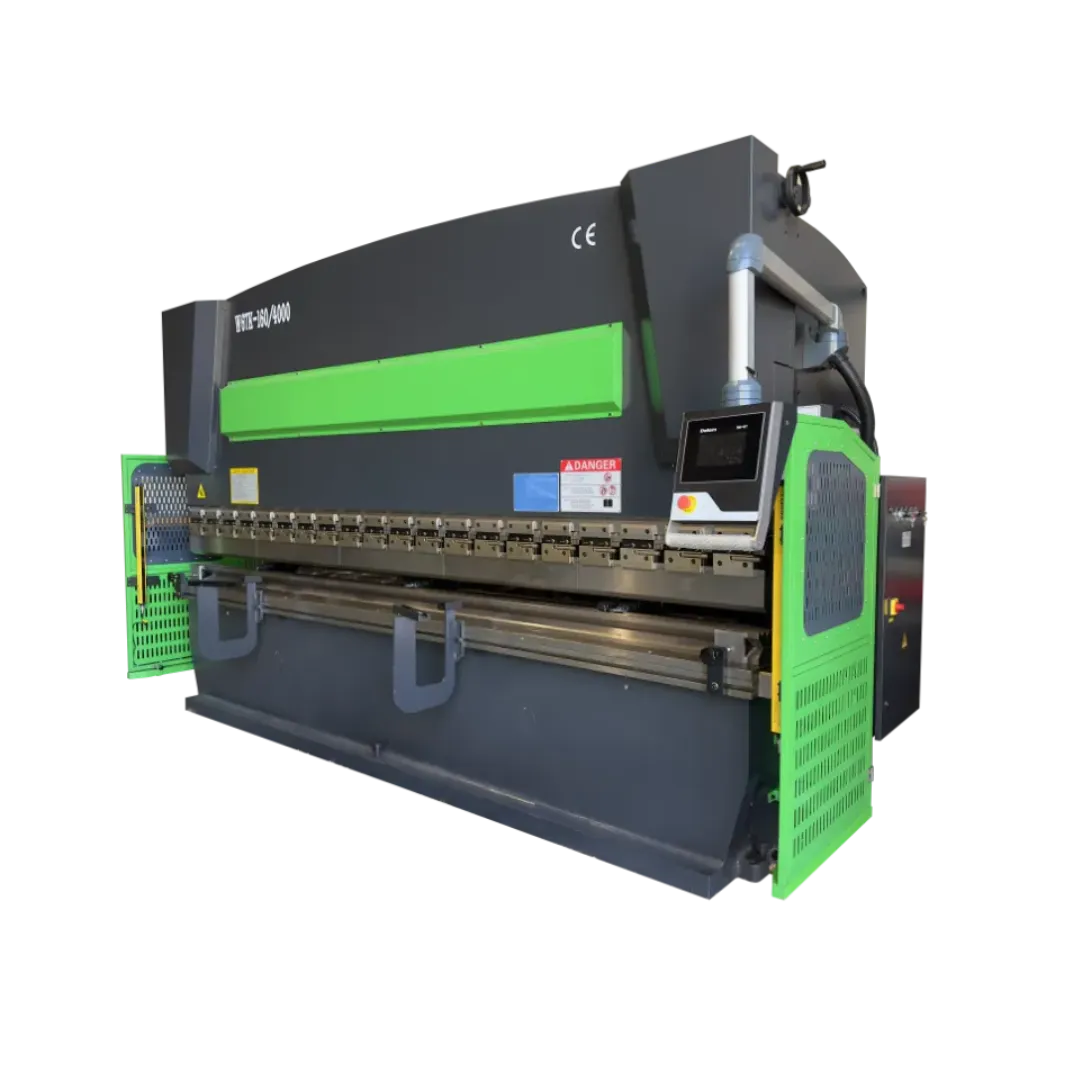

Discover high-performance, cost-effective Press Brake Folding Systems engineered for precision, reliability, and ease of use. Our range of torsion bar press brakes delivers accurate bending and consistent results, making them an excellent choice for fabrication workshops and industrial manufacturing. For synchronised press brake systems, please follow this link.

Intuitive CNC Control Systems for Precision Bending

Our press brakes feature advanced CNC control systems, including the Delem DA-41T touchscreen controller, enabling precise angle and back gauge adjustments. This user-friendly interface streamlines operations, improving setup efficiency and production accuracy.

Heavy-Duty Mono-Block Construction for Maximum Stability

Built with a rigid all-steel welded mono-block frame, our press brakes ensure minimal deflection under load, delivering consistent bending accuracy. Designed for durability and longevity, they perform reliably even in high-demand industrial environments.

Versatile Tooling for a Wide Range of Applications

Each press brake comes fully equipped with a complete set of Euro-style top tooling and an additional 800mm segmented section, allowing for efficient handling of diverse bending tasks. This versatility ensures precise results across multiple material types.

Motorised Back Gauge with Tiltable Finger Stops

Enhance bending precision and repeatability with our motorised back gauge system, featuring tiltable finger stops. This setup improves accuracy and speed, reducing setup times and optimising workflow efficiency.

Customisable Sizes & Bending Capacities

We offer press brakes from 1.5 meters to 5 meters in length, with bending capacities from 40 to 400 tons. This extensive range ensures a tailored solution for your specific sheet metal bending requirements.

High-Precision Bending with Consistent Results

Equipped with advanced hydraulic systems and precise back gauge positioning, our press brakes deliver exceptional accuracy for intricate shapes and complex bends, ensuring reliable, high-quality results in every application.

12 Months UK Warranty

Commissioning

Range of Options

Touchscreen

Easy to Operate

High Performance, Affordable Press Brake Machines

Our affordable press brake range delivers exceptional sheet metal bending capabilities with powerful features and precise performance. Designed for industrial reliability, these machines offer cost-effective solutions without compromising on accuracy, durability, or efficiency.

Intuitive Touchscreen Controls for Seamless Operation

Our press brakes are equipped with the DA-41T touch controller, offering a user-friendly interface for precise bending control. The 7-inch widescreen TFT display delivers clear visuals, while intuitive touch navigation simplifies programming, tool selection, and material setup. With memory storage for up to 100 programs, each with 25 steps, the DA-41T controller enhances efficiency, accuracy, and repeatability in metal forming tasks.

Versatile Press Brake Sizes & Capacities

Our press brakes are available in operating lengths from 1.5m to 5m and tonnages ranging from 40 to 400 tons, ensuring a solution for every metal fabrication requirement. Whether you need a compact press brake for small-scale production or a heavy-duty machine for large industrial applications, our range provides the perfect fit for precise and reliable bending operations.

Torsion Bar System for Enhanced Operator Control

The integrated torsion bar system ensures balanced ram movement, allowing for consistent, high-accuracy bends. This system makes operation easier to learn, reducing training time for new operators while maintaining superior bending precision.

Delem DA-41T touch screen control system

Easy to use touch screen interface for setting parameters and options

A wide range of capacities available

Heavy duty monoblock construction

Reliable, easy-to-use torsion bar system

Energy-Efficient Hydraulic System

Designed for cost-effective operation, our press brakes feature an energy-efficient hydraulic system that reduces power consumption while maintaining consistent pressure for smooth, high-precision bending results. This ensures long-term reliability with lower running costs.

Durable Precision-Machined Steel Frame

Our press brakes are built with a precision-machined steel frame, ensuring unmatched structural integrity and durability. The reinforced design minimises deflection under heavy loads, delivering consistent and accurate bending performance for years to come.

Exceptional Service & Support

Our expert UK-based service team provides comprehensive support, with access to online guides, telephone assistance, and professional engineering teams for seamless operation.

Comprehensive Overview of our Affordable Press Brake Range

The Mantech Press Brake lineup delivers precision, efficiency, and durability across a wide range of sizes and capacities. With options ranging from 1.5m to 5m in length and 40T to 400T in tonnage, our press brakes cater to diverse metal fabrication needs, ensuring high-accuracy bending for various industries. For customised press brake solutions tailored to your specific production requirements, contact our expert Sales Technicians at 0121 541 1444.

Heavy-Duty Construction for Long-Lasting Performance

Engineered with a welded all-steel mono-block frame, our press brakes provide exceptional strength and rigidity. This ensures minimal deflection under load, guaranteeing precise and reliable bending performance for demanding industrial applications.

Advanced Safety Systems for Operator Protection

Equipped with light curtain safety barriers, side and rear mechanical safety guards, and interlock switches, our press brakes prioritise operator safety, meeting strict industry safety standards to ensure secure and efficient operation.

Precision Adjustment for Seamless Bending

Our adjustable mechanical cams allow precise control over the upper position and work speed change points, enabling smooth transitions and optimal bending performance across different applications.

Intelligent CNC Control System

Featuring the Delem DA-41T CNC control, mounted on an ergonomic pendant system, our press brakes provide an intuitive touchscreen interface for accurate angle adjustments, tool selection, and efficient bending operations.

Accurate Ram Stroke for Consistent Bends

A motorised ram stroke control with precision mechanical depth stops ensures repeatable, high-accuracy bending with adjustable settings for customised performance on every job.

Versatile Tooling Configuration

Supplied with a standard top tool and a multi-V bottom tool, our press brakes offer versatile bending capabilities, allowing users to tackle a wide range of sheet metal applications with precision.

Motorised Back Gauge for Increased Accuracy

The high-precision motorised back gauge, equipped with tiltable finger stops, provides precise material positioning, improving repeatability and overall bending accuracy.

Adjustable Tonnage for Material Versatility

Our tonnage gauge and pressure switch allow operators to finely adjust bending force, ensuring optimal tonnage settings for different materials and thicknesses, maximising precision and efficiency.

Depth Stops for Precise Bending Control

Integrated depth stops provide accurate control over bending depth, ensuring consistent and repeatable results across all bending operations.

Customisable Dwell Time for Precision Forming

The adjustable dwell time feature ensures even pressure distribution, reducing spring-back effects and allowing for higher accuracy when working with thick or complex materials.

Front Support Arms for Sheet Stability

Adjustable front support arms provide enhanced stability and ease of use when handling large or heavy sheets, ensuring accurate positioning and operator efficiency during bending.

Flexible Single & Auto Cycle Modes

Easily switch between single-cycle and auto-cycle beam operation using a selector switch, offering flexibility for different bending tasks and optimised production efficiency.

Built-In Overload Protection for Machine Safety

Equipped with hydraulic and electrical overload protection, our press brakes safeguard both machine and operator, preventing damage and ensuring reliable, long-term performance.

Hands-Free Foot Pedal Control

The ergonomic foot pedal system provides hands-free operation, giving operators greater control while enhancing workflow efficiency and safety during bending processes.

Precision Tool Clamping System

Our Euro/System intermediate clamping ensures secure and accurate tool positioning, allowing for quick tool changes and efficient, precise bending operations.

High-Accuracy Back Gauge Assembly

A ball screw-driven back gauge guarantees smooth and precise positioning, improving accuracy and repeatability for consistent bending results on every job.

Multi-Step Program Storage for Efficiency

Store up to 100 programs, each containing 25 bend configurations. Manage beam stop, back gauge, angle input, and tool programming seamlessly, ensuring fast setup and increased productivity.

UK-Based Engineering & Technical Support

Our highly skilled UK-based engineers provide comprehensive installation, servicing, and training, ensuring seamless operation and ongoing support for your press brake system.

Reliable UK Warranty for Peace of Mind

All Press Brakes include a premium 12-month parts & labour warranty (excluding consumables), offering confidence in reliability and long-term performance.

Dedicated After-Sales Support

Our UK-based after-sales team provides lifetime assistance via email and telephone, ensuring you receive expert guidance and technical support whenever you need it.

Press Brake Tooling Options for Maximum Versatility

See below for the types of tooling our affordable torsion bar press brakes use. For specialised tooling configurations or custom solutions, please contact our team to discuss your specific requirements.

V-Dies – Versatile and Precise Bending Tools

V-Dies are the most common bottom dies used in press brakes, offering multiple opening sizes to accommodate various material thicknesses and bending applications.

Rotary Bending Dies – Efficient and Smooth Bending

Featuring a cylindrical design with an 88-degree V-notch, rotary bending dies provide reduced friction, ensuring smooth, precise bends while minimising material marking.

90-Degree Dies – Ideal for Bottom Bending Operations

90-degree dies are primarily used for bottom bending, delivering consistent and accurate bends. The die opening size is adjusted based on material thickness for optimal results.

Acute Angle Dies – Flexible Air Bending Solutions

Designed for air bending, these dies allow the creation of acute, 90-degree, and obtuse angles by adjusting the depth of the punch stroke, offering maximum flexibility in forming operations.

Gooseneck Dies – Perfect for Return Flanging

Gooseneck dies are engineered to provide clearance for pre-formed flanges, allowing complex bends without interference, making them essential for return flanging applications.

Offset Dies – One-Stroke Z-Bending Efficiency

Offset dies combine a punch and die set that creates two precise bends in one stroke, forming Z-shaped profiles efficiently and accurately for a variety of sheet metal applications.

Hemming Dies – Two-Stage Bending for Secure Edges

Hemming dies integrate an acute angle die with a flattening tool, producing secure, closed bends for reinforced sheet metal edges, commonly used in automotive and aerospace applications.

Seaming Dies – Precision Sheet Metal Edge Folding

Seaming dies are specialised tools designed to fold sheet metal edges with precision, creating strong, reliable seams for joining, strengthening, and reinforcement.

Our Most Popular Press Brake Models

Discover our best-selling Press Brake models, engineered for precision and versatility across various metal fabrication applications.

| Model Specifics | W67Y-40/1600 | W67Y-80/2500 | W67Y-80/3200 | W67Y-160/3200 |

|---|---|---|---|---|

| Working Length (mm) | 1600 | 2500 | 3200 | 3200 |

| Capacity (Tonnage) | 40 | 100 | 100 | 160 |

| Throat Gap (mm) | 200 | 250 | 400 | 400 |

| Standard MOT back gauge | 600 | 600 | 600 | 600 |

| Motor Power (kW) | 5 | 5.5 | 7.5 | 11 |

| Weight (tonnes) | 2.5 | 5 | 8.1 | 10.9 |

| Dimensions L/W/H (mm) | 2200 x 1400 x 2100 | 3000 x 1500 x 2300 | 3750 x 1800 x 2650 | 3750 x 1800 x 2650 |

All Press Brake Technical Data

Explore our complete range of Press Brake models, tailored to meet diverse bending requirements with precision and efficiency.

| Technical data Model | Nominal force (kN) | lengthof working table (mm) | distance between vertical columns (mm) | Throatdepth (mm) | Stroke (mm) | Max.Open height (mm) | Adjustment ofstroke (mm) | Motor power (kW) | Net weight (kg) | Dimensions (L*W*H) (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| W67Y-30/1320 | 300 | 1140 | 200 | 80 | 320 | 60 | 3 | 2000 | 1950*1420*2100 | |

| W67Y-30/1600 | 300 | 1420 | 200 | 80 | 320 | 60 | 3 | 2300 | 2280*1500*2100 | |

| W67Y-40/1320 | 400 | 1120 | 200 | 100 | 340 | 80 | 4 | 2200 | 1950*1420*2100 | |

| W67Y-40/1600 | 400 | 1400 | 200 | 100 | 340 | 80 | 4 | 3100 | 2150*1500*2100 | |

| W67Y-40/2000 | 400 | 1800 | 200 | 100 | 340 | 80 | 4 | 3300 | 2550*1500*2200 | |

| W67Y-40/2500 | 400 | 2300 | 200 | 100 | 340 | 80 | 4 | 3600 | 3100*1500*2200 | |

| W67Y-63/2500 | 630 | 2260 | 250 | 100 | 355 | 80 | 5.5 | 4800 | 3100*1600*2280 | |

| W67Y-63/3200 | 630 | 2960 | 250 | 100 | 355 | 80 | 5.5 | 5600 | 3800*1650*2280 | |

| W67Y-80/2500 | 800 | 2240 | 250 | 100 | 355 | 80 | 7.5 | 5900 | 3100*1650*2300 | |

| W67Y-80/3200 | 800 | 2940 | 250 | 100 | 355 | 80 | 7.5 | 6600 | 3900*1700*2300 | |

| W67Y-80/4000 | 800 | 3740 | 250 | 100 | 355 | 80 | 7.5 | 7800 | 4700*1600*2300 | |

| W67Y-100/2500 | 1000 | 2210 | 320 | 120 | 415 | 100 | 7.5 | 7300 | 3200*1700*2560 | |

| W67Y-100/3200 | 1000 | 2910 | 320 | 120 | 415 | 100 | 7.5 | 8100 | 3900*1800*2560 | |

| W67Y-100/4000 | 1000 | 3710 | 320 | 120 | 415 | 100 | 7.5 | 9200 | 4700*1900*2560 | |

| W67Y-125/2500 | 1250 | 2210 | 320 | 120 | 415 | 100 | 7.5 | 6500 | 3200*1700*2560 | |

| W67Y-125/3200 | 1250 | 2910 | 320 | 120 | 415 | 100 | 7.5 | 8150 | 3900*1800*2560 | |

| W67Y-125/4000 | 1250 | 3710 | 320 | 120 | 415 | 100 | 7.5 | 9800 | 4700*1900*2560 | |

| W67Y-160/3200 | 1600 | 2830 | 320 | 200 | 455 | 160 | 11 | 12000 | 6700*2180*2700 | |

| W67Y-160/4000 | 1600 | 3640 | 320 | 200 | 455 | 160 | 11 | 14000 | 4700*2200*2580 | |

| W67Y-160/6000 | 1600 | 5630 | 320 | 200 | 455 | 160 | 11 | 19500 | 6700*2200*2900 | |

| W67Y-200/3200 | 2000 | 2800 | 320 | 200 | 455 | 160 | 15 | 14500 | 3900*2200*2850 | |

| W67Y-200/4000 | 2000 | 3600 | 320 | 200 | 455 | 160 | 15 | 15400 | 4800*2180*3000 | |

| W67Y-200/6000 | 2000 | 5600 | 320 | 200 | 455 | 160 | 15 | 24600 | 6800*2200*3000 | |

| W67Y-250/3200 | 2500 | 2850 | 400 | 250 | 560 | 200 | 18.5 | 16000 | 3900*2280*2900 | |

| W67Y-250/4000 | 2500 | 3650 | 400 | 250 | 560 | 200 | 18.5 | 18800 | 4400*2280*3000 | |

| W67Y-250/6000 | 2500 | 5650 | 400 | 250 | 560 | 200 | 22 | 28800 | 6800*2200*3600 | |

| W67Y-300/3200 | 3000 | 2720 | 400 | 250 | 560 | 200 | 22 | 22800 | 3800*2200*3200 | |

| W67Y-300/4000 | 3000 | 3520 | 400 | 250 | 560 | 200 | 22 | 24900 | 4600*2200*3200 | |

| W67Y-300/6000 | 3000 | 5520 | 400 | 250 | 560 | 200 | 30 | 32000 | 6800*2200*3600 | |

| W67Y-400/3200 | 4000 | 2800 | 400 | 320 | 630 | 270 | 30 | 24000 | 3800*2500*3450 | |

| W67Y-400/4000 | 4000 | 3600 | 400 | 320 | 630 | 270 | 30 | 30000 | 4500*2500*3450 |

Customer Case Study

Kes Power & Lighting Ltd

Machine Purchased:

Press Brake model: Affordable Torsion 3.2m 100T Press Brake

Business Type:

Electrical Manufacturing

The Challenge:

Before working with Mantech, KES Power & Light Ltd were facing issues with an outdated press brake. The control system had become non-functional, creating unnecessary downtime and limiting production capabilities.

The Solution:

The Solution:

To address the problem, KES Power & Light Ltd invested in a new Press Brake from Mantech Machinery. The process was seamless from start to finish, with the team at Mantech providing a clear demonstration, handling the sale with professionalism, and ensuring a smooth delivery and commissioning process.

The Result:

With the new Press Brake in place, operations have become more efficient, reliable, and better suited to the demands of modern electrical manufacturing.

A great service from Mantech Machinery from first contact, demonstration, sale, delivery and commissioning

KES Power & Light Ltd

Southampton, Hampshire

Request a Quick Quotation

Ask us for a machinery quotation using our easy-to-fill form below.