Fibre Laser Cutting Power Guide: 3kW vs 6kW vs 12kW vs 20kW — Which Do You Really Need?

Introduction

2025–2026 UK & Ireland Edition

This updated 2025–2026 guide explains the real-world differences between 3kW, 6kW, 12kW and 20kW+ fibre laser cutters, using practical cutting capability and application data.

What Does Laser Power Actually Change?

1. Maximum Material Thickness

Higher power enables efficient cutting of thicker mild steel, stainless and aluminium.

2. Cutting Speed & Piercing Time

Higher power dramatically reduces cycle times, especially in 6–20mm steel.

3. Gas Pressure & Flow Requirements

Note: Laser power is only part of the equation. Nozzle selection, focus position, gas pressure, beam quality, machine rigidity and software also have a major impact.

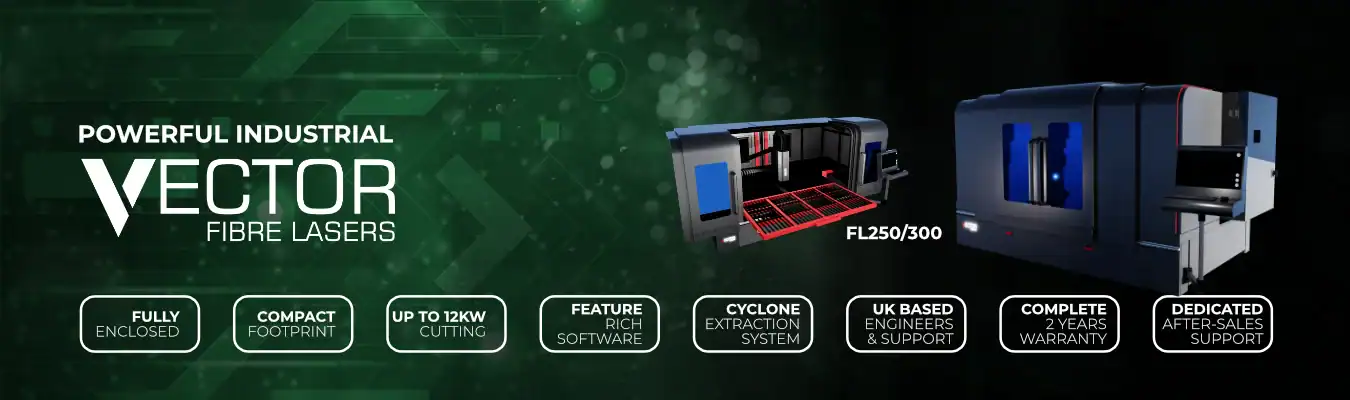

VECTOR Fibre Lasers (3–12kW)

Best For:

Smaller fabrication shops

Light engineering & thin sheet

Replacing plasma for cleaner edges

Lower running cost operations

Typical Cutting Scenario:

Mild Steel: Up to ~12mm N₂, 20mm O₂

Stainless Steel: ~8mm N₂

Aluminium: ~6mm N₂

Copper/Brass: 3–4mm

Ideal Customer:

Businesses whose workload is mostly 1–5mm sheet metal and want a clean, accurate, efficient and affordable fibre laser.

6kW Fibre Laser – The Most Popular Vector Configuration

General fabrication

Subcontractors

Mixed material cutting

Frequent 10–18mm work

Up to 20mm at capacity (lower quality cutting)

Typical Cutting Scenario:

Mild Steel: ~20mm N₂, 25mm O₂

Stainless Steel: ~12–15mm N₂

Aluminium: ~12mm N₂

Copper/Brass: ~6mm

Ideal Customer:

A versatile option for job shops and manufacturers needing the balance of speed, thickness capability and cost.

12kW Fibre Laser – The High-Speed Vector Production Machine

Medium-to-high volume production

Multi-shift operations

6–20mm mild steel at higher speed

High-speed stainless/aluminium cutting

Typical Cutting Scenario:

Mild Steel: 25mm+ N₂

Stainless Steel: ~20mm N₂

Aluminium: ~20mm N₂

Copper/Brass: 8–10mm

Ideal Customer:

Companies wanting an upgrade from 6kW, with high throughput on mid-to-thick materials.

SENFENG Fibre Lasers (20kW+)

Heavy plate cutting

24/7 automated production

Large manufacturers

High-speed cutting of thick stainless & aluminium

Clients needing the next level beyond 12kW

Typical Cutting Scenario:

Mild Steel: 30–50mm+ N₂ (machine dependent)

Stainless Steel: ~30mm N₂

Aluminium: ~30mm N₂

Copper/Brass: 10–12mm

Ideal Customer:

Fabricators requiring extreme speed on 8–20mm materials, or those cutting thick plate daily. Perfect when paired with Senfeng automation systems, such as load/unload towers and intelligent storage.

Which Power Should You Choose? (2025–2026 Quick Guide)

| Your Ideal Cutting Profile/Scenario | Recommended Power | Best Matched Machine |

|---|

| 1–5mm thin sheet, light fabrication | 3kW | Vector 3kW (Compact Models) |

| Mixed materials up to 18mm | 6kW | Vector FL250/300 6kW |

| High-volume production on 6–20mm | 12kW | Vector FL250/300 12kW |

| Thick plate or high-speed automation | 20kW+ | Senfeng 20kW–40kW |

Note: these values are based on maximum capacity (not production quality)

| Power level | Best use case | Max mild steel | Max stainless steel |

|---|---|---|---|

| 3kw (Vector | Thin sheet, light fabrication, low running cost | 18mm | 8mm |

| 6kW (Vector | Mixed fabrication, general job shop work | 20mm | 12mm |

| 12kW (Vector) | High-speed production, 6–20mm workloads | 25mm+ | 22mm |

| 20kW (Senfeng) | Heavy plate, high-volume, automation | 30-50mm | 30mm |

Air Cutting with Industrial Compressors (Cost-Effective Cutting in 2025–2026)

Air cutting is ideal for thin and medium-thickness mild steel, aluminium and galvanised sheet, making it a strong choice for general fabrication, signage, HVAC, agricultural equipment and high-volume part production. In many cases, air can even deliver faster cutting speeds than nitrogen on thin material while maintaining acceptable edge quality.

The key to successful air cutting is the quality of the compressor system. Fibre lasers require clean, dry, high-pressure air with stable flow rates. For this reason, Mantech supplies matched compressor packages built specifically for our Vector Fibre Lasers (3–12kW) and Senfeng high-power systems (20kW+), ensuring reliable performance and correct air delivery.

Air cutting is not recommended in scenarios where oxide-free edges, mirror finishes or high-end stainless components are required. However, for general production, it offers up to 90% lower operating cost, excellent cutting performance and a strong return on investment.

Looking at the Vector Fibre Laser range? use our cut parameter tool to work out your best option depending upon material and cut thickness