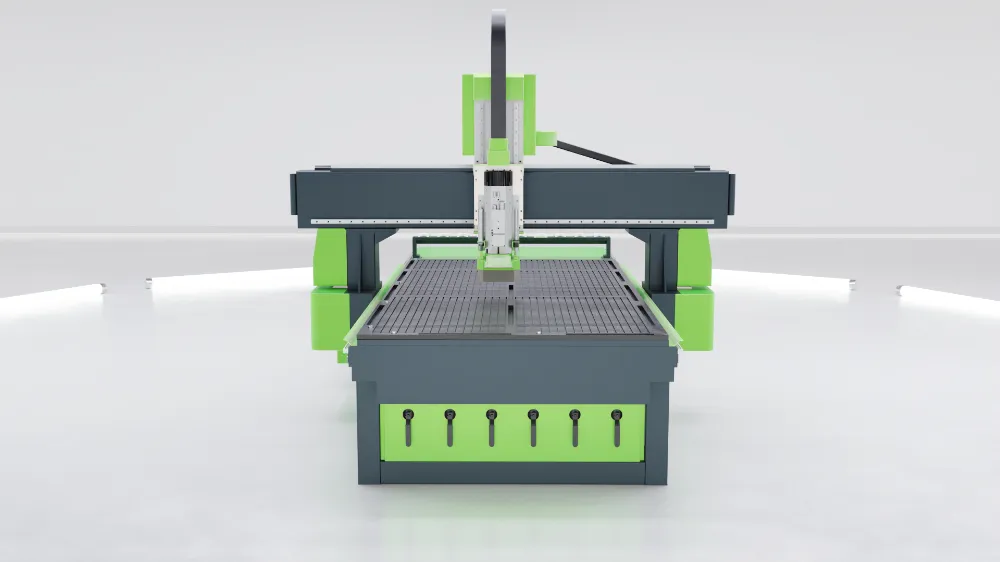

Falcon ATC CNC Routers – UK Automatic Tool Change CNC Machines

Full UK Warranty

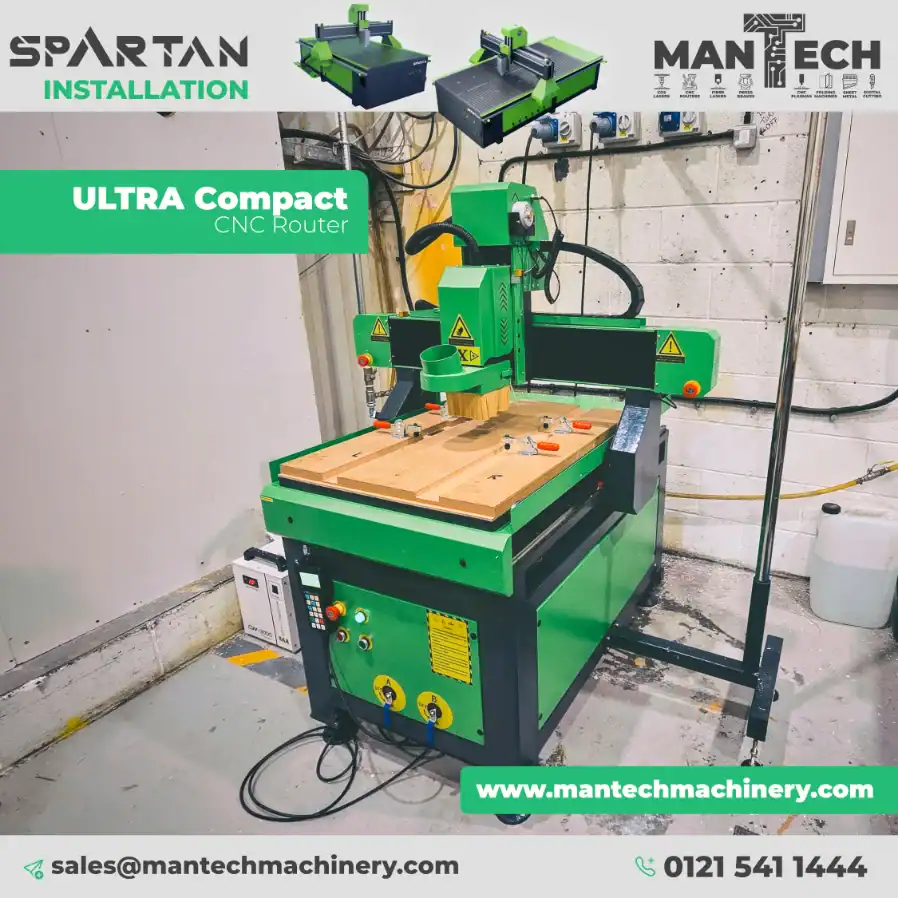

Delivery & Installation Inc

Auto Tool Change (ATC)

Production Ready CNC

UK Based Support & Training

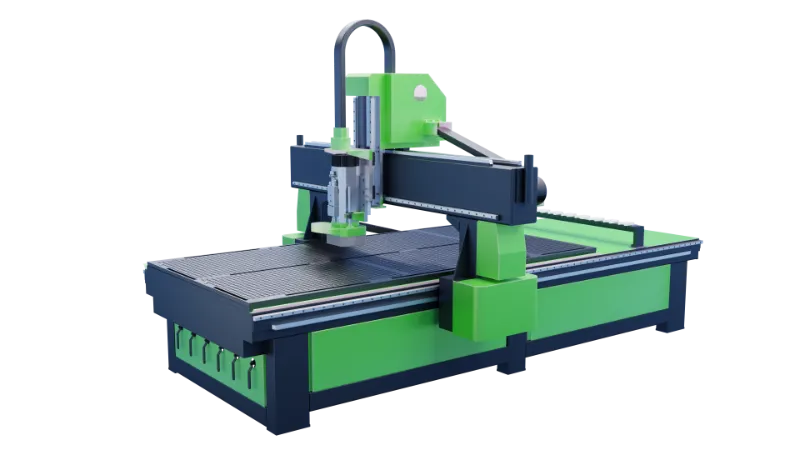

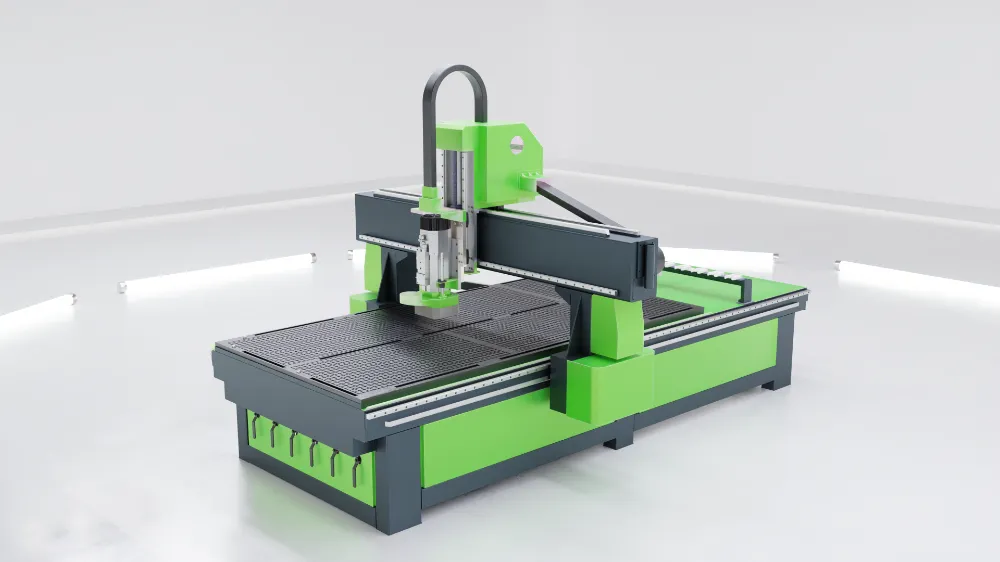

Industrial ATC CNC Design

Built for Demanding Production Environments

A Proven CNC Router Platform

Why Falcon ATC CNC Routers Deliver Productivity & Reliability

Which Falcon ATC CNC Router Is Right for Your Business?

The Falcon ATC CNC Router range is designed for workshops and manufacturers that require automated tool changing, consistent accuracy and improved production efficiency. Available in multiple table sizes, Falcon ATC machines support everything from compact workshops to high-throughput manufacturing environments. Each model is built on the same proven platform, allowing you to choose the right working area and configuration without compromising reliability or performance. Custom table sizes and configurations may be available. Please speak to our team for guidance.

Key considerations:

-

Compact working area

-

Automatic tool changing as standard

-

Ideal where space is limited

Key considerations:

-

Ideal for standard sheet materials

-

Automatic tool changer for multi-tool jobs

-

Improved workflow efficiency

Key considerations:

-

Larger working area than standard sheet sizes

-

Supports higher production volumes

-

Suitable for growing manufacturing operations

Key considerations:

-

Large-format cutting capability

-

Designed for demanding production workflows

-

Automatic tool changing for complex jobs

Key considerations:

-

Extra-large working area

-

Ideal for high-throughput production

-

Built for continuous operation

Optional productivity attachments:*:

-

APK9 Oscillating Knife

-

APD9 Drill Bank

Key considerations:

-

Custom table sizes available

-

Modular attachments to extend machine capability

-

Configured to suit specific production workflows

-

Supported by ManTech’s UK engineering team

*Optional Falcon ATC Attachments

-

Falcon APK9 Oscillating Knife Attachment: Designed for cutting foam, rubber, composites, packaging materials and soft substrates.

-

Falcon APD9 Drill Bank Attachment: Enables fast, accurate multi-hole drilling for cabinetmaking, furniture production and panel processing.

Not sure which configuration is right for your application? Speak to our team for guidance on Falcon ATC options and attachments.

For manufacturers seeking a more integrated control environment and long-term production stability, explore the Apollo ATC CNC router range.

Falcon ATC CNC Router – Key Specifications & Technical Overview

Compare Our most popular Ranges

A side-by-side overview to help you choose the right CNC router for your application and production needs.

Spartan | Falcon ATC | Apollo | Apollo 4 Axis | |

Tytpical Use | Entry-level routing | Production routing | Industrial production | Multi-angle machining |

Tool Change | Manual | Automatic (ATC) | Manual or ATC | Automatic (ATC) |

Axes | 3 Axis | 3 Axis | 3 Axis | 4 Axis (0–180°) |

Typical Materials | All CNC router models are suitable for wood, MDF, plastics and aluminium, with specialist configurations available for advanced or abrasive materials. | |||

Production Level | Light | Medium | High | Advanced |

Bed Sizes | Multiple options | Multiple options | Multiple options | Multiple options |

Product Link | ||||

Falcon ATC CNC Router – Technical Specifications & Model Compariso

The table below provides a side-by-side comparison of the core technical specifications across the Falcon ATC CNC Router range. Specifications may vary depending on configuration and optional attachments. Please contact our team for application-specific guidance.

Tip: Scroll horizontally to compare specifications across models.

| Specification | Falcon ATC 1313 | Falcon ATC 1325 | Falcon ATC 1530 | Falcon ATC 2030 | Falcon ATC 2040 | Custom Falcon ATC |

|---|---|---|---|---|---|---|

| Power Configuration | 3-phase | 3-phase | 3-phase | 3-phase | 3-phase | 3-phase |

| Control System | NK105 DSP controller with USB pendant | NK105 DSP controller with USB pendant | NK105 DSP controller with USB pendant | NK105 DSP controller with USB pendant | NK105 DSP controller with USB pendant | Syntech Control System (Tower) |

| Drive Motors | Delta servo drives | Delta servo drives | Delta servo drives | Delta servo drives | Delta servo drives | Delta servo drives |

| X-Axis Travel | 1300 mm | 1300 mm | 1300 m5 | 2000 mm | 2000 mm | As range |

| Y-Axis Travel | 1300 mm | 2500 mm | 3000 mm | 3000 mm | 4000 mm | As range |

| Z-Axis Travel | 300 mm (standard) | 300 mm (standard) | 300 mm (standard) | 300 mm (standard) | 300 mm (standard) | 300 mm (standard) |

| Spindle Power | 9.0 kW ATC | 9.0 kW ATC | 9.0 kW ATC | 9.0 kW ATC | 9.0 kW ATC | 9.0 kW ATC + Option |

| Spindle Type | Air-cooled ER32 ATC | Air-cooled ER32 ATC | Air-cooled ER32 ATC | Air-cooled ER32 ATC | Air-cooled ER32 ATC | Air-cooled ER32 ATC +Option |

| Tool Changer | Automatic tool changer | Automatic tool changer | Automatic tool changer | Automatic tool changer speed | Variable Automatic tool changer | Automatic tool changer +Option |

| Tool Positions | 10 tools (standard) | 10 tools (standard) | 10 tools (standard) | 10 tools (standard) | 10 tools (standard) | 10 tools (standard) |

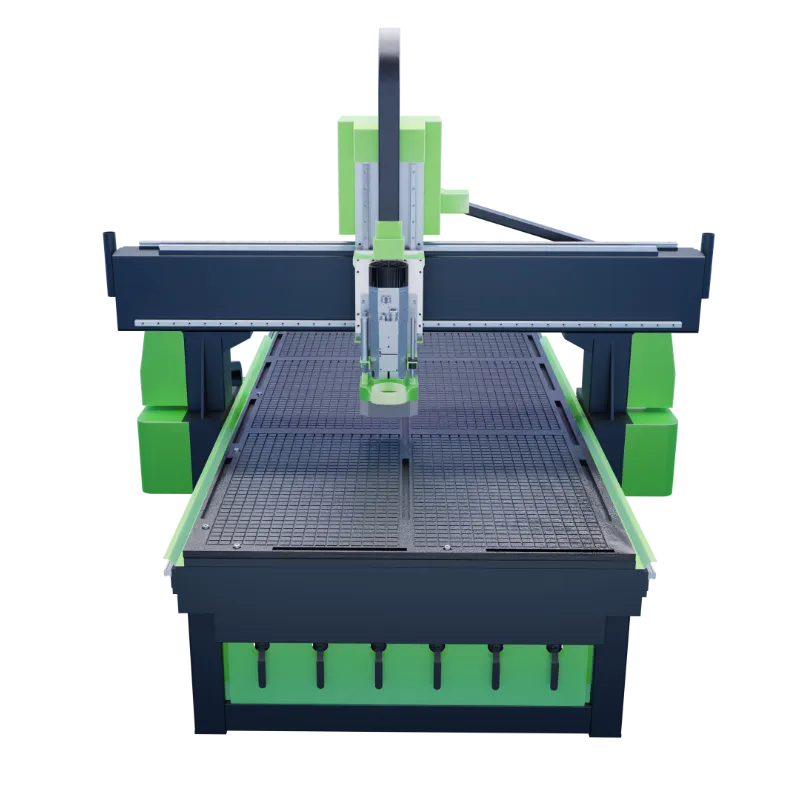

| X / Y Axis Drive | Helical rack and pinion | Helical rack and pinion | Helical rack and pinion | Helical rack and pinion | Helical rack and pinion | Helical rack and pinion |

| Z Axis Drive | TBI ballscrew | TBI ballscrew | TBI ballscrew | TBI ballscrew | TBI ballscrew | TBI ballscrew |

| Machine Frame | Heavy-duty welded steel construction | Heavy-duty welded steel construction | Heavy-duty welded steel construction | Heavy-duty welded steel construction | Heavy-duty welded steel construction | Heavy-duty welded steel construction |

| Vacuum Table Type | Matrix vacuum table | Matrix vacuum table | Matrix vacuum table | Matrix vacuum table | Matrix vacuum table | Matrix vacuum table |

| Vacuum Pump | Included | Included | Included (capacity dependent) | Included (capacity dependent) | Included (capacity dependent) | Included (capacity dependent) |

| Material Clamping | Integrated | Vacuum + T-slot clamps | Vacuum + T-slot clamps | Vacuum + T-slot clamps | Vacuum + T-slot clamps | Vacuum + T-slot clamps |

| Extraction System | Integrated extraction capability | Integrated extraction capability | Integrated extraction capability | Integrated extraction capability | Integrated extraction capability | Integrated extraction capability |

| Dust Collection | Suitable for external extraction | Suitable for external extraction | Suitable for external extraction | Suitable for external extraction | Suitable for external extraction | Suitable for external extraction |

| Electrical Supply | Configured to suit workshop power | Configured to suit workshop power | Configured to suit workshop power | Configured to suit workshop power | Configured to suit workshop power | Configured to suit workshop power |

| Installation Environment | Indoor workshop use | Indoor workshop use | Indoor workshop use | Indoor workshop use | Indoor workshop use | Indoor workshop use |

Optional Falcon ATC Attachments

Falcon ATC CNC Routers Are Used Across These Industries

Furniture & Cabinet Production

Joinery & Woodworking

Signmaking & Display Manufacturing

Prototyping & Product Development

Plastics, Composites & Sheet Materials

Light Industrial & Batch Production

Falcon ATC CNC Routers are designed for businesses that require automated tool changing, repeatable accuracy and efficient production across a wide range of materials and applications.

CNC Router Installations - Latest

Not sure which Falcon model is right for you? Our team can help.