Quick Fibre Laser Welder Quote

Customer Quotation Form

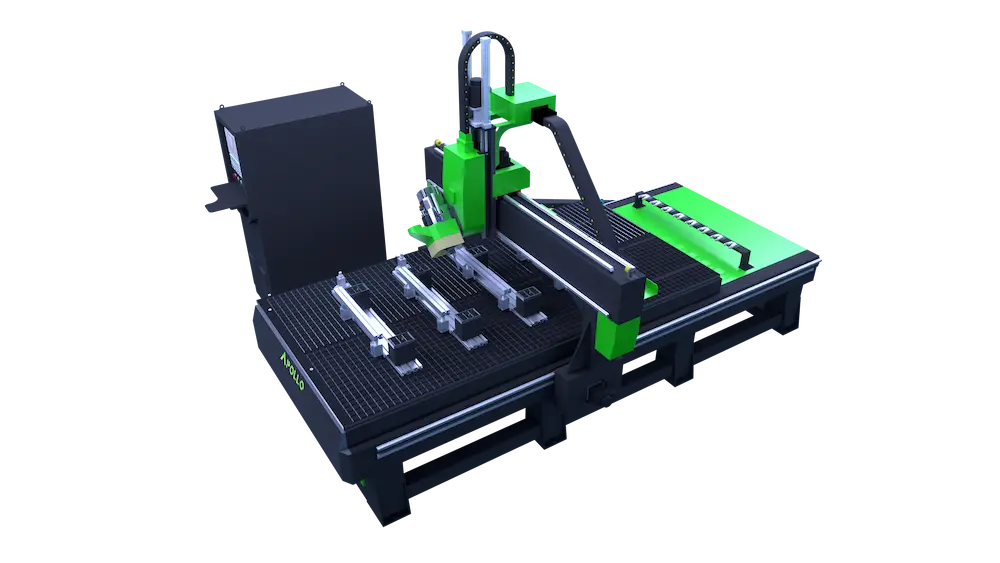

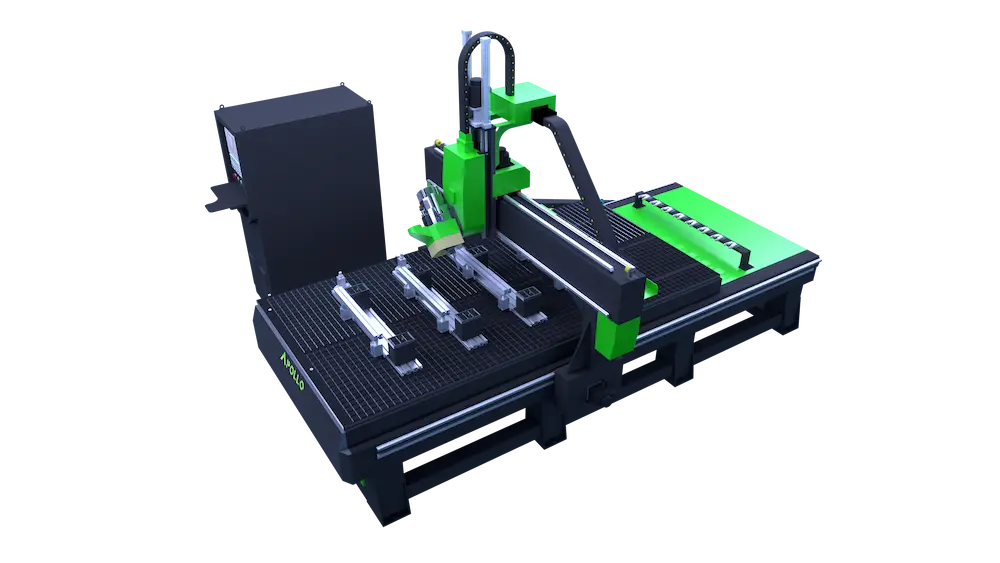

A fully featured CNC router that’s built like a tank and offers advanced functionality such as a 0-180 degree spindle adjustment for unrivalled output, perfect for any industry.

| Topic | Details |

|---|---|

| Introduction to Apollo 4 Axis CNC Router Range | Introduces a brand new range of 4 Axis CNC routers, equipped with the world-renowned Syntec control system and the all-new 4 Axis 9.0kW Auto Tool Change Spindle System. |

| Key Features | Control the unit via the control podium and the MPG pendant for precise control over your CNC router. It can also be connected to your network for easy file transfer to and from the CNC machine. |

| Service | Complete with our industry-leading 2-year parts and labour warranty. |

| 4 Axis Operation | This 4 Axis machine offers both side control and your standard 3 Axis CNC operation, which makes it perfect for processing doors, frames, and furniture. |

| Applications | Used in a variety of industries such as aerospace, woodworking, automotive, marine engineering, prototyping, fabrication, and more. |

| Drive Motors | With advanced closed-loop servo motors (YASKAWA), the Apollo 4 Axis offers high-speed operation with versatile productivity options. |

| Apollo 4 Axis Vs Other CNC Routers | The Apollo 4 Axis is equipped with a high-performance, air-cooled spindle with a Pneumatic clamping system and high spindle speeds. The router has a tooling capacity of up to 8 tools as standard (max of 10), held in a linear rack at the rear of the machine. |

| Materials Apollo 4 Axis CNC Router Can Handle | Corian and similar acrylic-based composites, acrylics, plastics, HDPE, Dibond – aluminium composites, soft metals like aluminium, brass, lead, foam and foam board, TRESPA, polystyrene, wood composites, rubber, Tufnol, vermiculite sheet, fibre board and so much more. |

| Summary of Apollo 4 Axis CNC Router Range | The Apollo 4 Axis is a versatile manufacturing companion that offers world-renowned controls and components, as well as 4 Axis operational capability. It is an excellent choice for any industry looking to produce high-quality output at a highly competitive purchase price. |

| Apollo 4 Axis Standard Features | Information |

|---|---|

| Control System | Syntec 4 axis/auto tool change control |

| High Performance Spindle System | 9.0KW (12hp) ER32 air cooled spindle system 24,000rpm with automatic tool change function. 8 x ISO 30 tool holders/positions. |

| Vacuum material holding system | The multi-zone vacuum allows for controlled vacuum areas across the bed, POD and Rail systems for side processing. |

| Mechanical drive | Helical rack and pinion X & Y axis, with reciprocating ball screw on the Z axis. |

| Drive system | Rapid Servo drives YASKAWA. |

| Linear guide rails/carriers | HIWIN oil inject centralised linear rail lubrication. |

| Material Positioning Stops/Guides | Pneumatic pop-up end stops for material location. |

| Vacuum system | Yes – Multi-zone matrix bed including pump system and filter. |

| Extraction system | Enhanced, ‘Focused’ dust extraction system included. |

| Tool cooling | Integrated pneumatic cutter cooling/lubrication system. |

| Safety features | Modular Safety fences with optical IR guarding. |

| Software package | AlphaCam Standard Is required (or similar – ask for options). |

| Delivery | UK Mainland included. (offloading and siting option available if required). |

| Installation | Our professional installation team will fully commission your new machine – It is the customer’s responsibility to ensure they have the correct electrical and air outputs (we will advise you on what is required). |

| Warranty | 24 months standard warranty with extended warranty periods available. |

| Available in the following bed sizes: |

|---|

| 1300 x 2500 |

| 1500 x 3000 |

| 2000 x 3000 |

| 2000 x 4000 |

| Custom bed sizes are also available. |

| Standard bed sizes (mm) |

| 600 x 900, 1300 x 1300, 1300 x 2500, 1500 x 3000, 2000 x 3000 (Ask for custom bed sizes) |

| Spindles |

| 2.2 – 6kW |

| Drive Motors |

| High performance stepper motors |

| Mechanical Drive |

| Ball screw XYZ (6090 model), ball screw on Z, helical rack and pinion on XY (1313 model up) |

| Control System |

| DSP |

| Tool Control |

| Manual tool change |

| Software |

| Vectric V Carve Pro |

| Warranty |

| 12 months parts and labour |

| Extra Information |

| A versatile CNC router that’s our most affordable system to yet! |

| Standard bed sizes (mm) |

| 1300 x 1300, 1300 x 2500, 1500 x 3000, 2000 x 3000, 2000 x 4000 (Ask for custom bed sizes) |

| Spindles |

| 9.0kW ATC air-cooled |

| Drive Motors |

| Delta Servo Drives |

| Mechanical Drive |

| Reciprocating ball screw on Z with a helical rack and pinion on XY |

| Control System |

| DSP |

| Tool Control |

| Auto tool change |

| Software |

| Vectric V Carve Pro |

| Warranty |

| 12 months parts and labour |

| Extra Information |

| Perfect for customers wanting a high performance machine without the cost. Pop-up location stops |

| Standard bed sizes (mm) |

| 1300 x 1300, 1300 x 2500, 1500 x 3000, 2000 x 3000, 2000 x 4000 (Ask for custom bed sizes) |

| Spindles |

| 7.5kW Air-cooled |

| Drive Motors |

| Delta Servo Drives |

| Mechanical Drive |

| Reciprocating ball screw on Z with a helical rack and pinion on XY |

| Control System |

| M-TECH Motion Control (PC Podium) |

| Tool Control |

| Manual change (can be upgraded) |

| Software |

| Vectric V Carve Pro |

| Warranty |

| 2-years parts and labour |

| Extra Information |

| High-performance CNC router that’s been built like a tank. Upgradable to ATC. Pop-up location stops. |

| Standard bed sizes (mm) |

| 1300 x 1300, 1300 x 2500, 1500 x 3000, 2000 x 3000, 2000 x 4000 (Ask for custom bed sizes) |

| Spindles |

| 9.0kW ATC Air-cooled |

| Drive Motors |

| Delta Servo Drives |

| Mechanical Drive |

| Reciprocating ball screw on Z with a helical rack and pinion on XY |

| Control System |

| M-TECH Motion Control (PC Podium) |

| Tool Control |

| Full auto tool change |

| Software |

| Vectric V Carve Pro |

| Warranty |

| 2-years parts and labour |

| Extra Information |

| High-performance CNC router that’s been built like a tank with full automatic tool change. Pop-up location stops |

| Standard bed sizes (mm) |

| 1300 x 2500, 1500 x 3000, 2000 x 3000, 2000 x 4000 (Ask for custom bed sizes) |

| Spindles |

| 9.0kW ATC Air-cooled 0-180 degree 4-axis |

| Drive Motors |

| Yaskawa or Maxsine Servo Drives |

| Mechanical Drive |

| Reciprocating ball screw on Z with a helical rack and pinion on XY |

| Control System |

| Syntec Control |

| Tool Control |

| Full auto tool change |

| Software |

| Alphacam |

| Warranty |

| 2-years parts and labour |

| Extra Information |

| High-performance 4-axis ATC CNC Router with 0-180 degrees of machining power. Pop-up location stops |