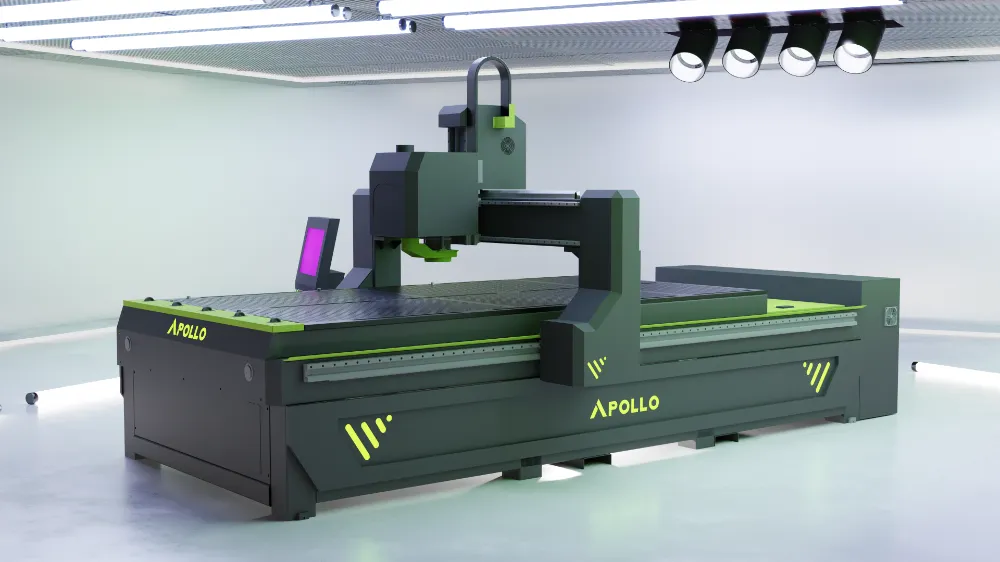

Apollo M Professional CNC Router – UK-Engineered Industrial Manual Tool Change Machine

Full UK Warranty

Delivery Included

Installation Included

M-TECH Control

Exceptional Service

Precision CNC Performance

Heavy-Duty Industrial Build Quality

UK-Engineered Reliability & Support

Apollo M Professional CNC Routers For All Industries

Explore the Advanced Apollo M CNC Routers with MTECH Motion Control

Compare Our most popular Ranges

A side-by-side overview to help you choose the right CNC router for your application and production needs.

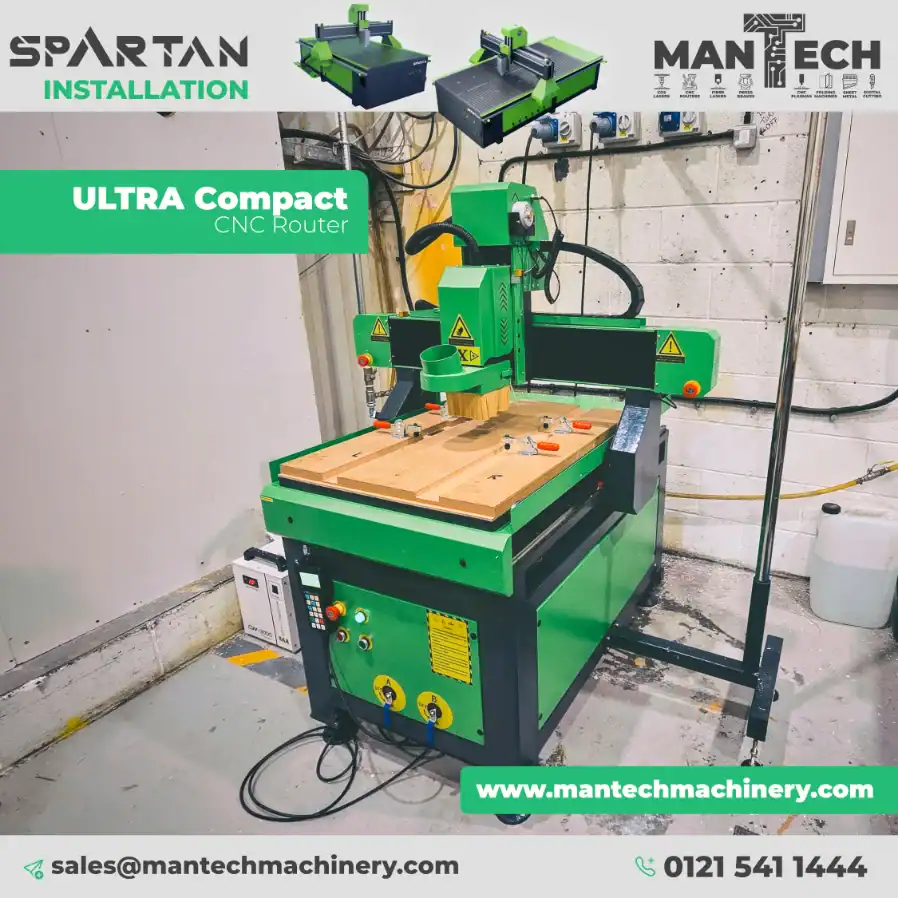

Spartan | Falcon ATC | Apollo | Apollo 4 Axis | |

Tytpical Use | Entry-level routing | Production routing | Industrial production | Multi-angle machining |

Tool Change | Manual | Automatic (ATC) | Manual or ATC | Automatic (ATC) |

Axes | 3 Axis | 3 Axis | 3 Axis | 4 Axis (0–180°) |

Typical Materials | All CNC router models are suitable for wood, MDF, plastics and aluminium, with specialist configurations available for advanced or abrasive materials. | |||

Production Level | Light | Medium | High | Advanced |

Bed Sizes | Multiple options | Multiple options | Multiple options | Multiple options |

Product Link | ||||

Unmatched Precision and Versatility with MTECH Powered CNC Routers

Side view

Rear View

Side View

Overview and Features

| Apollo M CNC Datasheet | description |

|---|---|

| Table Sizes | Table sizes available: 1300 x 1300 mm / 1300 x 2500 mm / 1600 x 3100 mm / 2050 x 3050 mm / 2050 x 4000 mm (custom sizes available) |

| Spindle system | 9.0KW (12hp) ER32 air cooled spindle system 24,000rpm with automatic tool change function. 8 x ISO 30 tool holders/positions. |

| Bridge Z Height | 300 mm standard bridge height |

| Mechanical Drive | Helical rack and pinion, reciprocating ball screw drives on Z. |

| Drive System | Delta servo drive system – exceptional performance with lower power consumption |

| Control System | In-house developed M-TECH motion control that includes a Touch based PC based system, wireless pendant and podium |

| Linear Guide Rails | HIWIN oil inject centralised linear rail lubrication. |

| Material Positioning Stops | Pneumatic pop-up end stops for material location |

| Vacuum Table Type | Yes – Multi-zone matrix bed with touch screen activation controls, including pump system and filter. |

| Tool Cooling System | Integrated pneumatic cutter cooling/lubrication system. |

| Extraction System | Yes included |

| Safety Features | Modular Safety fences with optical IR guarding. |

| Software Package Included | M-TECH Control & Vectric V Carve Pro (Optional AlphaCAM) |

| Installation & Training | Our installation team carries out installation and safety training, giving you the confidence to use the machine before they leave. |

| Aftersales | After-sales service is UK based and available to all of our customers if needed. Lifetime technical support via email and telephone. |

| Warranty | All Apollo CNC Routers come with our leading 2 years parts & labour warranty (does not include consumables). |

Discover the Advantages of the Apollo M CNC Router Range?

The Apollo M (Manual) CNC Router is a cutting-edge solution, fully designed in the UK, offering an impressive range of features rarely found in its price category.

Built for Performance and Reliability

With a rigid, stress-tested body and premium components, the Apollo M provides exceptional durability and precision. Combined with first-class service from Mantech Machinery Ltd, this CNC router is a top choice for workshops. Every Apollo CNC router includes professional installation and training by our skilled, friendly engineers.

MTECH Motion Control System

Each Apollo CNC Router is equipped with our in-house developed MTECH Motion Control System, delivering unmatched control and customisation. Its intuitive interface allows granular adjustments for optimal performance and efficiency.

Upgradeable to Auto Tool Change

The Apollo M offers a unique upgrade path to Auto Tool Change, enabling you to future-proof your investment without needing a new machine. Purchase the manual model and upgrade later, saving money while maintaining flexibility.

Applications Across Industries

The Apollo range is versatile and widely used across multiple sectors, including:

- Furniture Production

- Aerospace

- Ply Lining

- Marine Engineering

- Auto Engineering

- Educational Institutions

- Construction

- And many more.

A Class-Leading CNC Solution

Designed through extensive research and development, the Apollo M CNC Router excels in a variety of manufacturing tasks, such as:

- Sign making and custom furniture production.

- Corian work surfaces and toolbox foam inserts.

- Profile cutting, wood carving, and soft metal processing.

- Conveyor belt production, exhibition stands, and POS manufacturing.

Apollo M vs. Apollo ATC

While the Apollo M lacks the Auto Tool Change feature of the Apollo ATC, it remains a powerhouse CNC machine. For workshops not requiring auto tool change, the Apollo M is a dependable and cost-effective solution.

However, if your needs evolve, every Apollo M CNC Router can be upgraded to Auto Tool Change at any time, ensuring long-term value and adaptability.

Your Partner in Precision and Affordability

The Apollo M CNC Router delivers speed, reliability, and affordability, backed by Mantech’s commitment to providing feature-rich machinery tailored to your needs. This machine is the perfect addition to any workshop looking to maximise efficiency and versatility.

Powerful Spindles

Every Apollo High-Performance CNC Router is equipped with a robust 7.5kW air-cooled electro spindle mounted on the bridge, delivering outstanding performance at the core of its operation.

Do You Supply Software?

Yes, all of our CNC routers come with Vectric VCarve Pro as standard, with optional upgrades to Aspire or Alphacam for advanced requirements.

About VCarve Pro:

Vectric VCarve Pro is a powerful yet user-friendly software solution designed for CNC router applications. It provides:

- 2D Design Capabilities: Create complex profiles, pockets, drill paths, and inlays.

- V-Carving Textures: Add intricate textures to your designs for professional results.

- 3D Model Integration: Import and machine unlimited Vectric 3D clipart or single model files.

- Production Features: Unlimited job sizes, true shape nesting, and job setup sheets for streamlined workflows.

Training on VCarve Pro is included with every CNC router, ensuring you can maximise its capabilities and achieve your production goals.

Is Training and Delivery Included?

Absolutely! All Apollo CNC Routers include delivery and full training. Our team ensures you understand how to operate both the machine and the software, giving you the confidence to produce professional-grade projects right away.

| Wood | Plastics | Composites and other |

|---|---|---|

| Oak | Acrylic | ACM (like Alcubond, Dibond) |

| Birch wood | Polycarbonate | Foamex |

| MFC | Tufnol | Composite Fibreboard |

| Plywood | PVC | Solid Surface (Corian etc) |

| Walnut | Peek | Carbon Fibre |

| Pine | ABS | Graphite |

| Leather | HPDE | Tool Box Foam |

| Redwood | HPL | Laminated Woods |

| OSB board | Yes | Vermiculite Board |

| Cedar | Plexiglass | Trespa |

| Cherry | Nylon | Aluminium |

| Elm | Delrin | Brass |

Our CNC Routers are Great For

CNC Router Installations - Latest

Not sure which Apollo M model is right for you? Our team can help.