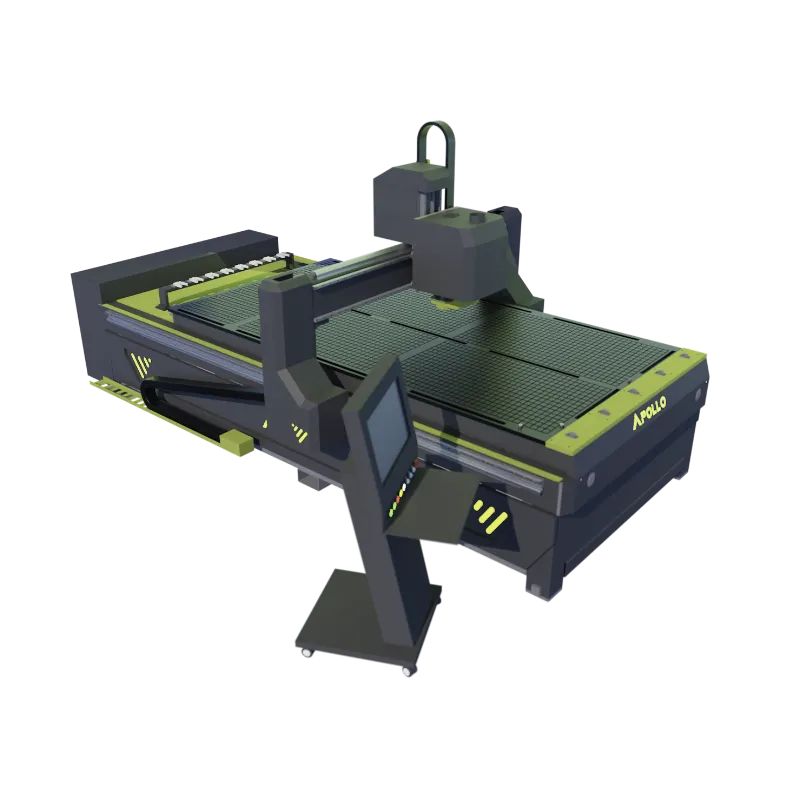

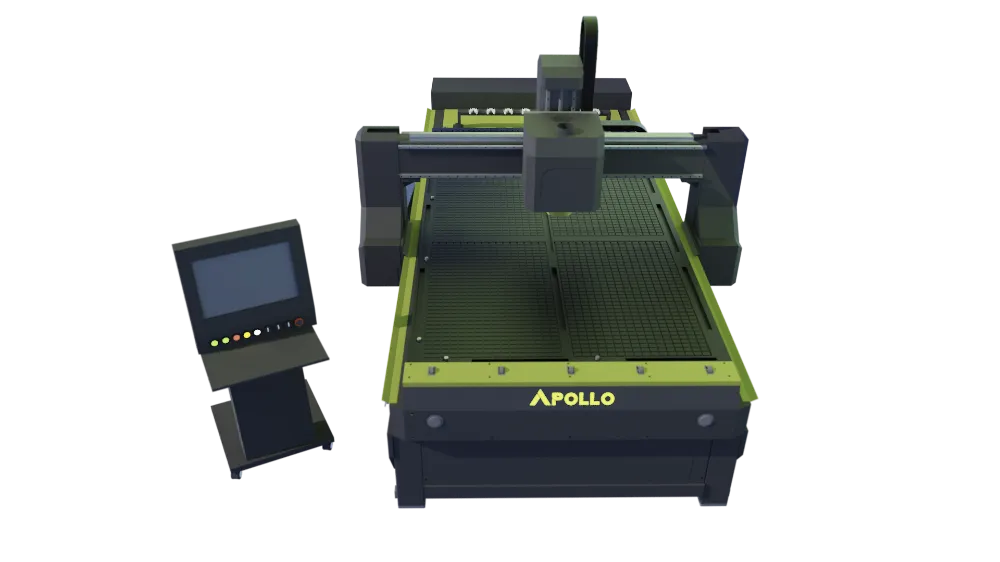

Apollo ATC CNC Routers Production-Grade Automatic Tool Change CNC Machines for Manufacturing

Full UK Warranty

Delivery & Installation

Auto Tool Change

Production Ready

UK Engineering Support

Reliable Automatic Tool Change for Production

Heavy-Duty Industrial Build Quality

Engineered, Installed & Supported in the UK

Why Apollo ATC CNC Routers Are Specified for Production Manufacturing

Which Apollo ATC CNC Router Is Right for Your Production Requirements?

The Apollo ATC CNC router range is specified for manufacturers running demanding production workflows where rigidity, duty cycle and long-term accuracy are critical.

Key considerations:

-

Compact working area with industrial build quality

-

Automatic tool change as standard

-

Ideal where space is limited but production accuracy is critical

Key considerations:

-

Optimised for standard sheet sizes

-

Reliable ATC performance for multi-tool jobs

-

Balanced footprint for production workshops

Key considerations:

-

Larger working area for increased capacity

-

Suitable for higher production volumes

-

Designed for consistent performance over long runs

Key considerations:

-

Large-format cutting capability

-

Designed for demanding production schedules

-

Automatic tool changing for complex workflows

Key considerations:

-

Extra-large working area

-

Built for continuous operation

-

Suitable for high-throughput production

Key considerations:

-

Custom table sizes available on request

-

Configured to suit material formats and production workflow

-

Built on the same heavy-duty Apollo ATC platform

Supplied with installation and training, with UK-based after-sales support.

Not sure which configuration is right for your application? Speak to our team for guidance on Apollo ATC options.

Apollo ATC CNC Router – Key Specifications & Technical Overview

-

1300 × 1300 mm

-

1300 × 2500 mm

-

1500 × 3000 mm

-

2000 × 3000 mm

-

2000 × 4000 mm

Apollo specifications are engineered around reliable long-term production performance, designed to reduce downtime and improve throughput across demanding manufacturing workloads.

Apollo ATC CNC Router – Technical Specifications & Model Comparison

The Apollo ATC CNC Router range is built on a heavy-duty industrial platform, with specifications optimised for continuous production and multi-tool machining. The table below outlines the standard configuration across the Apollo ATC range.

| Specification | Apollo ATC 1313 | Apollo ATC 1325 | Apollo ATC 1530 | Apollo ATC 2030 | Apollo ATC 2040 | Custom Apollo ATC |

|---|---|---|---|---|---|---|

| Power Configuration | 3-phase | 3-phase | 3-phase | 3-phase | 3-phase | 3-phase |

| Control System | M-TECH CNC Motion Control (PC-based, touchscreen & MPG) | M-TECH CNC Motion Control (PC-based, touchscreen & MPG) | M-TECH CNC Motion Control (PC-based, touchscreen & MPG) | M-TECH CNC Motion Control (PC-based, touchscreen & MPG) | M-TECH CNC Motion Control (PC-based, touchscreen & MPG) | M-TECH CNC Motion Control (PC-based, touchscreen & MPG) |

| Drive Motors | Delta servo drives | Delta servo drives | Delta servo drives | Delta servo drives | Delta servo drives | Delta servo drives |

| X-Axis Travel | 1300 mm | 1300 mm | 1300 mm | 2000 mm | 2000 mm | As range |

| Y-Axis Travel | 1300 mm | 2500 mm | 3000 mm | 3000 mm | 4000 mm | As range |

| Z-Axis Travel | 300 mm (standard) | 300 mm (standard) | 300 mm (standard) | 300 mm (standard) | 300 mm (standard) | 300 mm (standard) |

| Spindle Power | 9.0 kW ATC | 9.0 kW ATC | 9.0 kW ATC | 9.0 kW ATC | 9.0 kW ATC | 9.0 kW ATC + Option |

| Spindle Type | Air-cooled ISO30 ATC | Air-cooled ISO30 ATC | Air-cooled ISO30 ATC | Air-cooled ISO30 ATC | Air-cooled ISO30 ATC | Air-cooled ISO30 ATC |

| Tool Holder | ISO 30 | ISO 30 | ISO 30 | ISO 30 | ISO 30 | ISO 30 |

| Tool Changer | Automatic tool changer | Automatic tool changer | Automatic tool changer | Automatic tool changer speed | Variable Automatic tool changer | Automatic tool changer +Option |

| Tool Positions | 8 tools | 8 tools | 8 tools | 8 tools | 8 tools | 8 tools |

| X / Y Axis Drive | Helical rack and pinion | Helical rack and pinion | Helical rack and pinion | Helical rack and pinion | Helical rack and pinion | Helical rack and pinion |

| Z Axis Drive | TBI ballscrew | TBI ballscrew | TBI ballscrew | TBI ballscrew | TBI ballscrew | TBI ballscrew |

| Machine Frame | Heavy-duty welded steel construction | Heavy-duty welded steel construction | Heavy-duty welded steel construction | Heavy-duty welded steel construction | Heavy-duty welded steel construction | Heavy-duty welded steel construction |

| Vacuum Table Type | Multi-zone vacuum table | Multi-zone vacuum table | Multi-zone vacuum table | Multi-zone vacuum table | Multi-zone vacuum table | Multi-zone vacuum table |

| Vacuum Zones | Touchscreen selectable | Touchscreen selectable | Touchscreen selectable | Touchscreen selectable | Touchscreen selectable | Touchscreen selectable |

| Material Clamping | Vacuum + T-slot clamps | Vacuum + T-slot clamps | Vacuum + T-slot clamps | Vacuum + T-slot clamps | Vacuum + T-slot clamps | Vacuum + T-slot clamps |

| Location Stops | Pneumatic pop-up | Pneumatic pop-up | Pneumatic pop-up | Pneumatic pop-up | Pneumatic pop-up | Pneumatic pop-up |

| Extraction System | Integrated extraction capability | Integrated extraction capability | Integrated extraction capability | Integrated extraction capability | Integrated extraction capability | Integrated extraction capability |

| Dust Collection | Suitable for external extraction | Suitable for external extraction | Suitable for external extraction | Suitable for external extraction | Suitable for external extraction | Suitable for external extraction |

| Typical Application | Compact production | Sheet processing | Higher throughput | Large-format production | High-capacity production | Non-standard production |

| Installation & Training | Included | Included | Included | Included | Included | Included |

| Warranty (*ex consumables) | 2-year parts & labour* | 2-year parts & labour* | 2-year parts & labour* | 2-year parts & labour* | 2-year parts & labour* | 2-year parts & labour* |

Optional Falcon ATC Attachments

Compare Our most popular Ranges

A side-by-side overview to help you choose the right CNC router for your application and production needs.

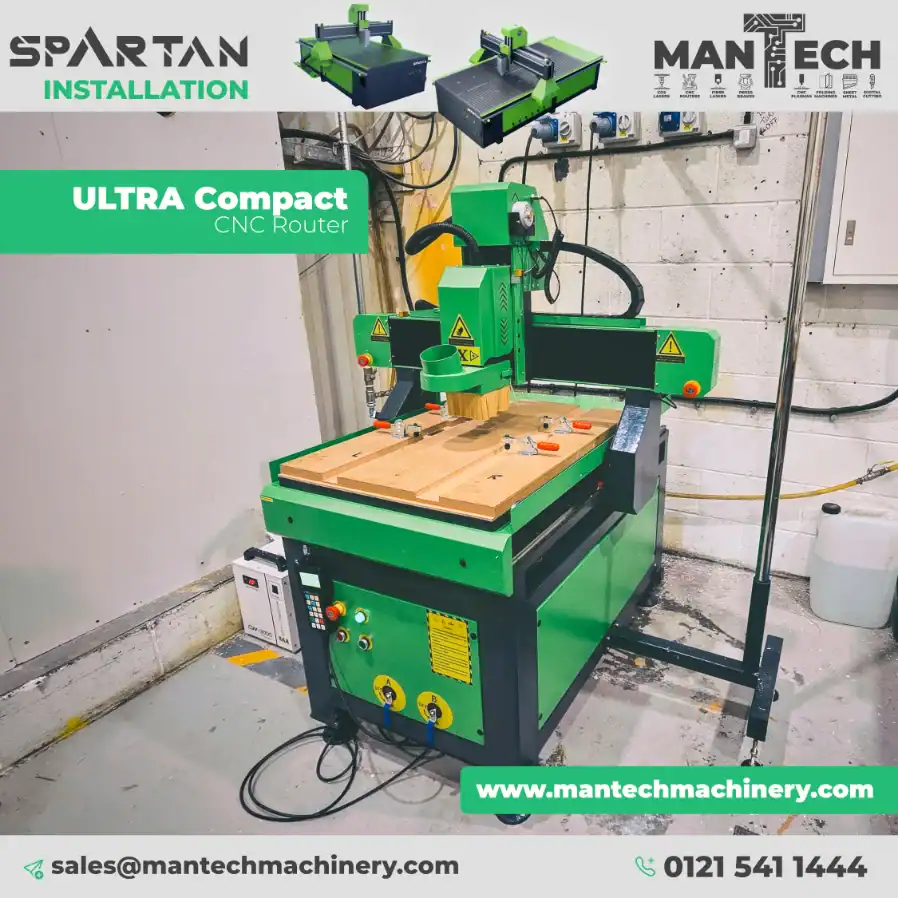

Spartan | Falcon ATC | Apollo | Apollo 4 Axis | |

Tytpical Use | Entry-level routing | Production routing | Industrial production | Multi-angle machining |

Tool Change | Manual | Automatic (ATC) | Manual or ATC | Automatic (ATC) |

Axes | 3 Axis | 3 Axis | 3 Axis | 4 Axis (0–180°) |

Typical Materials | All CNC router models are suitable for wood, MDF, plastics and aluminium, with specialist configurations available for advanced or abrasive materials. | |||

Production Level | Light | Medium | High | Advanced |

Bed Sizes | Multiple options | Multiple options | Multiple options | Multiple options |

Product Link | ||||

Apollo ATC CNC Routers Are Specified for Production in These Industries

Furniture & Cabinet Manufacturing

Joinery & Architectural Woodwork

Signmaking & Display Production

Plastics, Composites & Sheet Materials

Nested-Based Manufacturing

Light Industrial & Repeat Production

Typical applications include nested cabinet production, furniture components, architectural joinery, signage and panel processing, as well as plastics and composite sheet machining where consistent output and reduced operator intervention are required.

Customer Case Study

T&E Displays

Business Type:

The Challenge:

The Solution:

Customer Case Study

Broom Joinery Ltd

Business Type:

The Challenge:

The Solution:

CNC Router Installations - Latest

Not sure which Apollo ATC model is right for you? Our team can help.