Industrial CNC Routers for Wood, Plastics & Aluminium

Our CNC router range includes the Spartan CNC router range, Falcon CNC routers, and the Apollo CNC router series, with advanced multi-axis CNC routing options available.

Trusted by manufacturers across the UK

What’s Included With Every Mantech CNC Router

Delivery Provided as Standard

Professional Installation Included

Vectric Software Included

Operator Training Included

Extraction & Vacuum Included

UK Warranty Included

Affordable, High-Performance, Industrial CNC Routers for the UK Market

Precision. Power. Proven Performance and Affordability.

Popular CNC Routers used by Customers in Woodworking, Sign Making, Fabrication and more.

Our CNC routers are used across furniture manufacturing, sign making and industrial sheet processing. Designed for reliability and consistent performance, our range supports a wide variety of production environments and material types.

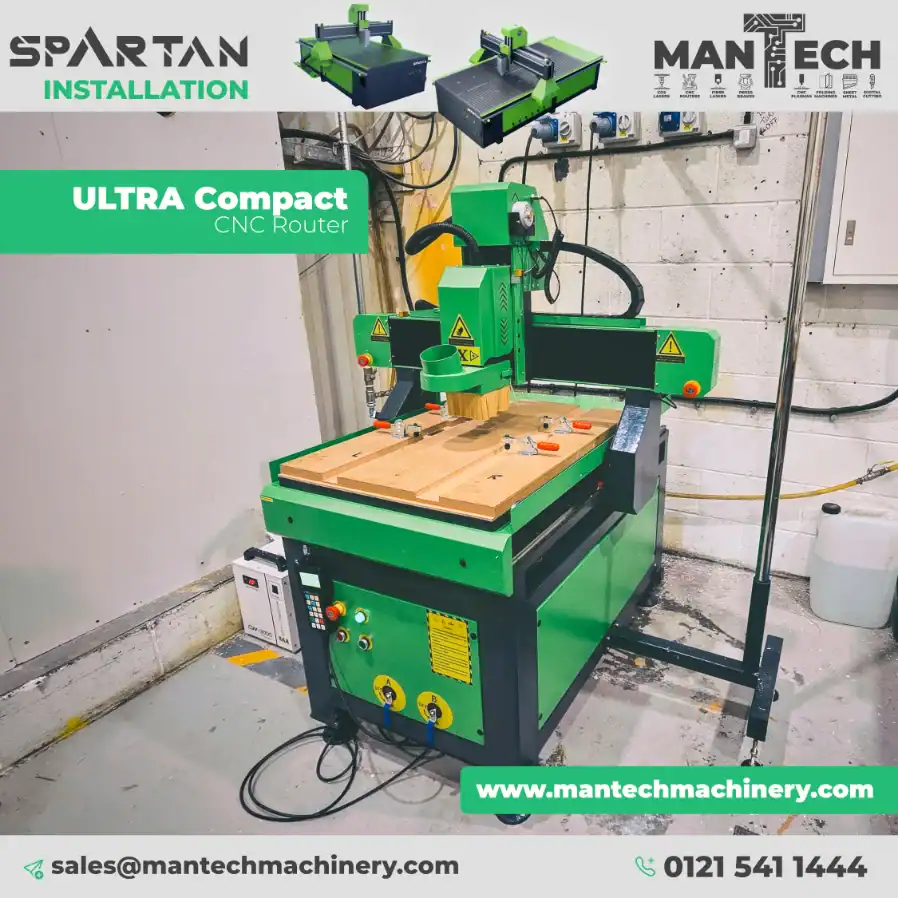

Spartan Series - Entry Level CNC Router

Materials: Wood, MDF, plastics, light aluminium

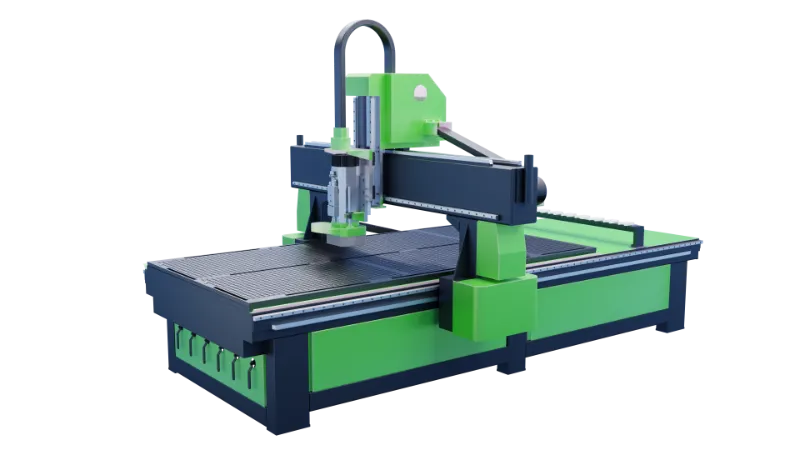

Falcon ATC – Affordable Auto Tool Change CNC Router

Materials: Wood, MDF, plastics, light aluminium

Apollo M – Manual Tool Change Powerhouse

Materials: Wood, MDF, ACM, plastics, foam

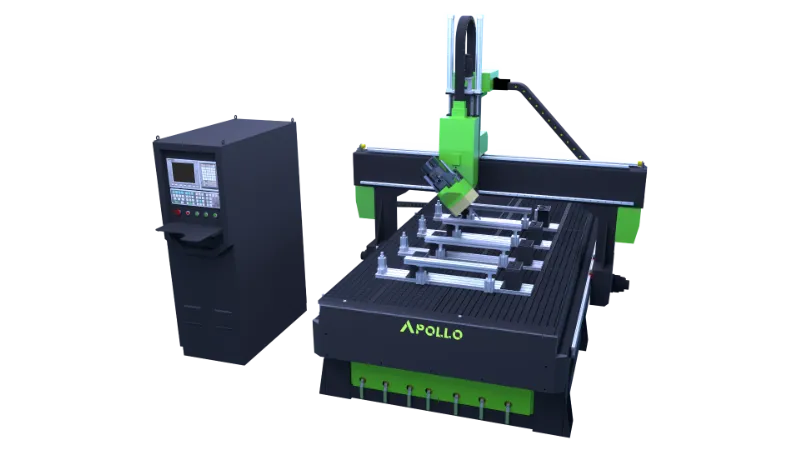

Apollo ATC – Professional Production CNC Router

Materials: Wood, MDF, ACM, plastics, foam

Apollo 4 Axis – Multi-Angle Machining CNC Router

Materials: Wood, MDF, ACM, plastics, foam

Apollo 5 Axis – Advanced 3D CNC Router

Materials: Wood, MDF, tooling board, plastics, foam

The Apollo 5 Axis CNC router delivers full simultaneous 5-axis movement for advanced shaping and complex geometries. Designed for demanding applications such as mould making, prototyping and curved surface machining, it offers maximum flexibility and precision in a single production-ready system.

Twin-Bed CNC Routers – Parallel Routing Efficiency

Materials: Wood, MDF, plastics, composites

Twin-Bed CNC routers are designed for continuous production environments where efficiency is critical. With dual working zones, operators can load one bed while the other is machining, making them ideal for panel shops, exhibition builders and packaging manufacturers looking to maximise output and minimise idle time.

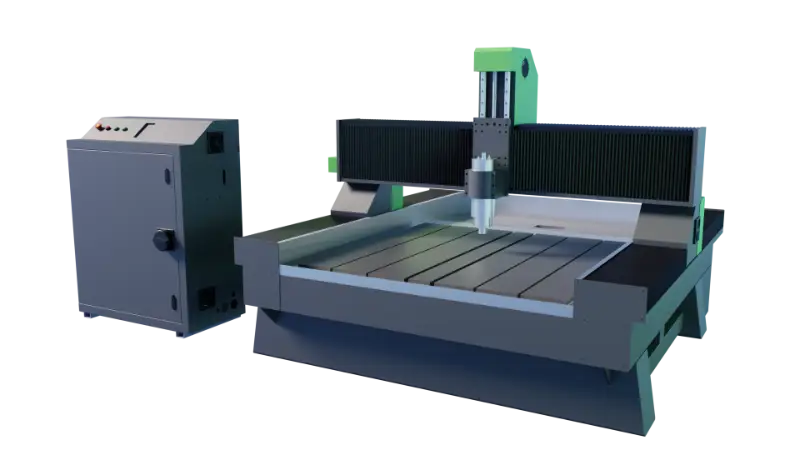

Stone-Tech CNC – Stone, Quartz & Marble Machining

Materials: Granite, quartz, marble, engineered stone

The Stone-Tech CNC router is engineered for cutting heavy and abrasive materials such as stone and quartz. Featuring reinforced components, water mist cooling and corrosion-resistant finishes, it provides a reliable, production-ready solution for stone masons, kitchen fabricators and specialist stone applications.

Compare Our most popular Ranges

A side-by-side overview to help you choose the right CNC router for your application and production needs.

Spartan | Falcon ATC | Apollo | Apollo 4 Axis | |

Tytpical Use | Entry-level routing | Production routing | Industrial production | Multi-angle machining |

Tool Change | Manual | Automatic (ATC) | Manual or ATC | Automatic (ATC) |

Axes | 3 Axis | 3 Axis | 3 Axis | 4 Axis (0–180°) |

Typical Materials | All CNC router models are suitable for wood, MDF, plastics and aluminium, with specialist configurations available for advanced or abrasive materials. | |||

Production Level | Light | Medium | High | Advanced |

Bed Sizes | Multiple options | Multiple options | Multiple options | Multiple options |

Product Link | ||||

How to Choose the Ideal Industrial CNC Router

Selecting the perfect CNC Router involves considering your material requirements, production needs, and the size of your workspace.

Not sure which CNC router is right for your application?

Speak to a CNC routing specialist →

Materials You Can Machine with CNC Routers

Industrial CNC routers are widely used to machine a range of sheet and solid materials across manufacturing, signage and joinery applications.

CNC Router Software Solutions

It enables 2D design creation with profile, pocket, drill, and inlay toolpaths, along with v-carving textures. Import and machine unlimited Vectric 3D clipart or individual model files effortlessly. The Pro version also offers unlimited job sizes, true shape nesting, and detailed job setup sheets, making it ideal for production settings. Training on VCarve Pro is included with every CNC router purchase to ensure seamless integration into your operations.

Your FAQs Answered

What is a CNC Router used for?

A CNC router is used to cut, engrave, and shape materials like wood, plastic, aluminium, foam, and composites. It’s commonly used in industries such as sign-making, cabinetry, set design, marine, aerospace, and furniture production.

What's the difference between 3-axis and 4-axis CNC routers?

A 3-axis CNC router moves along the X, Y, and Z axes, ideal for flat work. A 4-axis router adds spindle rotation (usually 0–180 degrees), allowing angled cuts, side drilling, and more complex geometry. It’s perfect for parts like chair legs, mouldings, or curved panels.

Who should use a CNC router with automatic tool change (ATC)?

ATC routers are ideal for businesses running multiple tooling operations per job—like drilling, profiling, and pocketing—without stopping production. They save time, reduce manual errors, and increase throughput in busy workshops.

Is the Falcon ATC router suitable for production work?

Yes, the Falcon ATC is designed for compact workshops that still demand high output. It includes a 9.0 kW spindle and Delta servos, making it a reliable and space-efficient option for manufacturers who need fast tool changes and consistent performance.

What can I do with a 4-axis CNC router like the Apollo?

The Apollo 4 Axis can machine parts at multiple angles using its rotating spindle. It’s excellent for stair components, complex mouldings, and projects that need more than just top-down routing. It also handles standard 3-axis tasks with ease.

Do your CNC routers come with training and support?

Yes, all our routers come with installation, onsite training, and lifetime technical support. We also offer remote guidance, servicing, and software setup to ensure you’re fully equipped from day one.

Can your CNC routers run on single-phase power?

Many of our entry-level and mid-range models can be configured for single-phase power. This is ideal for smaller workshops without access to 3-phase supply. Just ask during the quoting stage.

Do you offer finance options for CNC routers?

Yes, we offer flexible financing, including lease and purchase options. Our team can help you structure a plan that fits your business and cash flow, often with tax benefits. Finance is offered through a third-party partner; customers are more than welcome to use their own service.

CNC Router Installations - Latest

FREE CNC Router Job Costing Tool for CNC Router Users

Whether you’re a business looking to quote for a new CNC job or an individual working on a personal project, our CNC project cost estimator provides a free, fast and reliable way to understand the financial implications of your machining requirements in the UK.

Calculate now