UK CNC Router Machines – Trusted by Woodworkers, Sign Makers and Industrial Firms Nationwide

Delivery Provided as Standard

Installation Included

Software Included

Training Included

Extraction & Vacuum Included

UK Warranty Included

Affordable, High-Performance, Industrial CNC Router Machines for the UK Market

Precision. Power. Proven Performance.

Popular CNC Router Machines used by Customers in Woodworking, Sign Making, Fabrication and more.

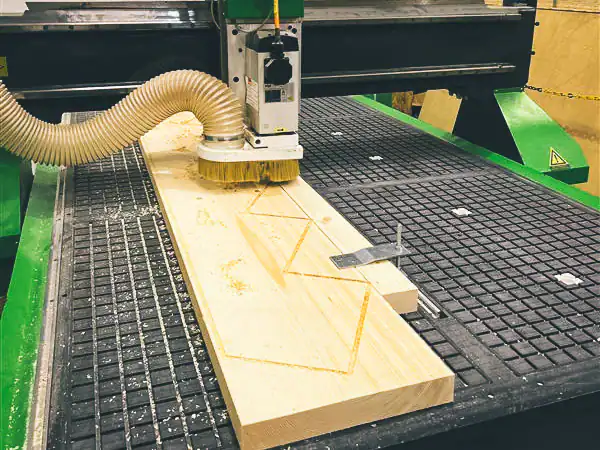

Mantech's range of CNC Routers are capable of being used in industries like woodworking, plastics fabrication, engineering, automotive applications, education, campervan and vehicle conversions, kitchen cabinets, worktops, and so much more.

Spartan Series - Entry Level CNC Router

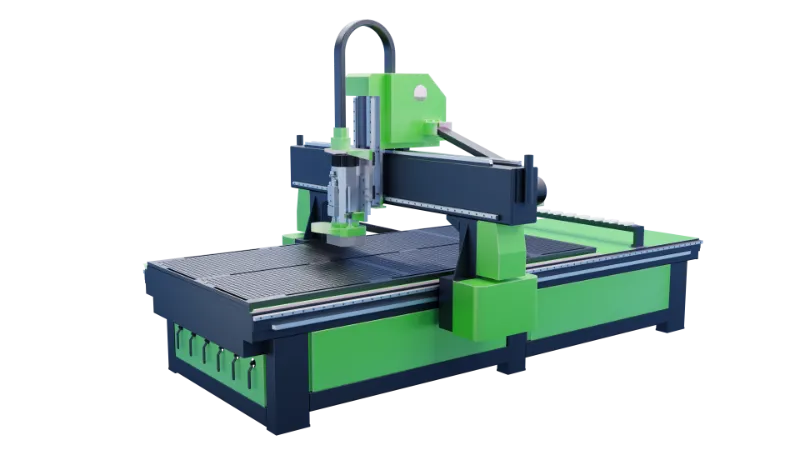

Falcon ATC – Compact with Big Capability

Apollo M – Manual Tool Change Powerhouse

Apollo ATC – Automatic Tool Change Efficiency

Apollo 4 Axis – Multi-Angle Machining

Apollo 5 Axis – Complex 3D Flexibility

Twin-Bed CNC Routers – Parallel Routing Efficiency

Designed for volume cutting, the Twin-Bed series allows you to load one side while the other is machining, keeping downtime to a minimum. Ideal for high-output panel shops, exhibition firms, and packaging cutters, this system saves time, boosts output, and fits seamlessly into fast-paced workflows.

Stone-Tech CNC – For Stone, Quartz & Marble

Stone-Tech takes the proven performance of our router platform and reinforces it for heavy, abrasive materials like granite, quartz, and marble. With water mist cooling, upgraded spindle bearings, and corrosion-resistant finishes, it’s a turnkey solution for stone masons, kitchen fabricators, and bespoke memorial work.

CNC Router Tooling & Accessories

Explore our extensive range of CNC Router tooling from our parts and consumables store. Suitable for materials like wood, MDF, plywood, acrylic, and composites, we stock tools such as compression bits (coated and uncoated), single and double flute, upcut, downcut, and 90-degree V-bits. Our pricing is competitive, and tooling can be delivered with your machine. We also supply CNC Router parts compatible with our machinery and other brands.

Included with Every CNC Router

Every Mantech CNC Router is supplied as a complete, ready-to-run package. We don’t believe in hidden extras and were upfront about any customer responsibilities – from delivery and installation to full training and after-sales support, everything you need to start cutting with confidence is included. Whether you’re a first-time buyer or upgrading to an industrial-grade system, your new CNC router arrives fully configured, tested, and supported by our UK-based engineering team.

Delivery & Installation

Included

Your CNC router will be delivered directly to your premises by our logistics team and installed by qualified Mantech engineers. Each machine is set up, levelled, and tested on-site to ensure optimal accuracy and performance. We handle commissioning, calibration, and safety checks so you can begin production immediately. Our team will also connect the machine to your chosen extraction system and confirm spindle direction, tool offsets, and software communication — giving you a seamless start from day one.

Software & Training Included

Every Mantech CNC router comes with fully licensed CAD/CAM software, intuitive yet powerful tools for designing and generating cutting paths. During installation, we provide hands-on operator training tailored to your experience level. You’ll learn how to create toolpaths, set zero points, adjust spindle speeds, and safely run production files. Our goal is to ensure every operator leaves confident and capable of achieving precision results, no matter the material or complexity of the job.

Vacuum, Extraction & Warranty Included

Every Mantech CNC router comes with fully licensed CAD/CAM software, intuitive yet powerful tools for designing and generating cutting paths. During installation, we provide hands-on operator training tailored to your experience level. You’ll learn how to create toolpaths, set zero points, adjust spindle speeds, and safely run production files. Our goal is to ensure every operator leaves confident and capable of achieving precision results, no matter the material or complexity of the job.

Compare Our most popular Ranges

Most Affordable

Spartan CNCExtras: Specialist tooling, MDF/fine dust extraction filters.

Auto Tool Change

Falcon CNCExtras: Specialist tooling, MDF/fine dust extraction filters. Drill bank, oscillating knife system (factory order and runs on Syntec not DSP),

Professional CNC

Apollo CNCExtras: Specialist tooling, MDF/fine dust extraction filters. ATC upgrade.

0-180 degs of Flexibilty

Apollo 4 AxisExtras: Specialist tooling, MDF/fine dust extraction filters.

How to Choose the Ideal Industrial CNC Router

Selecting the perfect CNC Router involves considering your material requirements, production needs, and the size of your workspace.

Selecting the correct CNC router bed size is critical to ensuring your router meets your production needs. Start by assessing the materials and designs you plan to work on and determine the largest size you will need to accommodate. For smaller tasks, a 600 x 900 mm bed like those in our Spartan range may be sufficient.

If you require larger working areas for advanced applications, our Falcon and Apollo ranges offer sizes up to 2000 x 4000 mm, providing ample space for bigger projects. Additionally, custom bed sizes can be designed to meet specific requirements, offering maximum flexibility for your operations.

ATC systems allow programmed tool paths to be executed seamlessly, enabling the machine to automatically select, retrieve, and swap tools without manual intervention.

For operations requiring these capabilities, consider the Falcon ATC or Apollo ATC ranges, which are equipped with advanced tool-changing functions to significantly reduce production cycle times.

For businesses requiring advanced functionality, consider machines equipped with M-TECH CNC motion control or Syntec systems, perfect for dual bed, oscillating knife, drill bank, or 4-axis operations.

The Apollo range, including Apollo M and ATC versions, delivers exceptional performance. For side drilling and cutting, the Apollo 4 Axis ATC is a standout choice, featuring a 9kW air-cooled spindle capable of rotation for side processing. This model also includes pod and rail systems to elevate workpieces for added versatility.

The Apollo 5 Axis offers an extra axis, enabling advanced three-dimensional machining with complex geometries.

If maximum productivity is a priority, dual-bed CNC routers allow simultaneous loading and operation for seamless efficiency.

For stone cutting and engraving, the Stonetech CNC router, with its powerful spindle and constant flow cooling, is the ideal solution.

Visual Learning Tips and CNC Buying Guide CNC Router

Why not follow our visual learning tips or our CNC router buying guide to help make purchase decisions.

Materials you can cut, engrave CNC Router Machine

Additional Materials a CNC Router Can Process

CNC Router Software Solutions

It enables 2D design creation with profile, pocket, drill, and inlay toolpaths, along with v-carving textures. Import and machine unlimited Vectric 3D clipart or individual model files effortlessly. The Pro version also offers unlimited job sizes, true shape nesting, and detailed job setup sheets, making it ideal for production settings. Training on VCarve Pro is included with every CNC router purchase to ensure seamless integration into your operations.

Recent CNC Router Customer Case Studies

Customer case studies – CNC routers used by British manufacturers such as:

Sign Making

T&E Displays

Business Type:

The Challenge:

The Solution:

Solid Surface Materials

TFSE Products Ltd

Business Type:

The Challenge:

The Solution:

The Result:

Joinery Firm

Broom Joinery Ltd

Business Type:

The Challenge:

The Solution:

Wood-Burning Stoves

Stove Spares Ltd

Business Type:

The Challenge:

The Solution:

The Result:

Timber Framed Housing

CITU

Business Type:

The Challenge:

The Result:

Your FAQs Answered

What is a CNC Router used for?

A CNC router is used to cut, engrave, and shape materials like wood, plastic, aluminium, foam, and composites. It’s commonly used in industries such as sign-making, cabinetry, set design, marine, aerospace, and furniture production.

What's the difference between 3-axis and 4-axis CNC routers?

A 3-axis CNC router moves along the X, Y, and Z axes, ideal for flat work. A 4-axis router adds spindle rotation (usually 0–180 degrees), allowing angled cuts, side drilling, and more complex geometry. It’s perfect for parts like chair legs, mouldings, or curved panels.

Who should use a CNC router with automatic tool change (ATC)?

ATC routers are ideal for businesses running multiple tooling operations per job—like drilling, profiling, and pocketing—without stopping production. They save time, reduce manual errors, and increase throughput in busy workshops.

Is the Falcon ATC router suitable for production work?

Yes, the Falcon ATC is designed for compact workshops that still demand high output. It includes a 9.0 kW spindle and Delta servos, making it a reliable and space-efficient option for manufacturers who need fast tool changes and consistent performance.

What can I do with a 4-axis CNC router like the Apollo?

The Apollo 4 Axis can machine parts at multiple angles using its rotating spindle. It’s excellent for stair components, complex mouldings, and projects that need more than just top-down routing. It also handles standard 3-axis tasks with ease.

Do your CNC routers come with training and support?

Yes, all our routers come with installation, onsite training, and lifetime technical support. We also offer remote guidance, servicing, and software setup to ensure you’re fully equipped from day one.

Can your CNC routers run on single-phase power?

Many of our entry-level and mid-range models can be configured for single-phase power. This is ideal for smaller workshops without access to 3-phase supply. Just ask during the quoting stage.

Do you offer finance options for CNC routers?

Yes, we offer flexible financing, including lease and purchase options. Our team can help you structure a plan that fits your business and cash flow, often with tax benefits. Finance is offered through a third-party partner; customers are more than welcome to use their own service.

FREE CNC Router Job Costing Tool for CNC Router Users

Whether you’re a business looking to quote for a new CNC job or an individual working on a personal project, our CNC project cost estimator provides a free, fast and reliable way to understand the financial implications of your machining requirements in the UK.

Calculate now

Quick Guides - CNC Router

CNC Router Maintenance Tips for New Owners (Video)

We’ve created a practical video guide (watch above) that walks you through the key areas of preventative maintenance for your

Discover now

Best CNC Routers in the UK (2025 Buyer’s Guide)

CNC routers are among the most versatile machines for UK manufacturers, sign-makers, and woodworking businesses. Check out our new buyer's

Discover now

9 Essential Monthly Maintenance Checks for Your CNC Router

If you’re new to CNC or just invested in your first Mantech CNC Router, it’s important to understand that regular

Discover now

How to Set the Start PointOn Your CNC (Falcon/Spartan)

Setting Homing Sequence for YourSpartan or Falcon CNC Router

How to Beginners Guide to Loadinga Program on a Falcon CNC

A Beginners Guide to CNC Router Best Practices

How to Check & Maintain YourVacuum Pump Filter - CNC Router

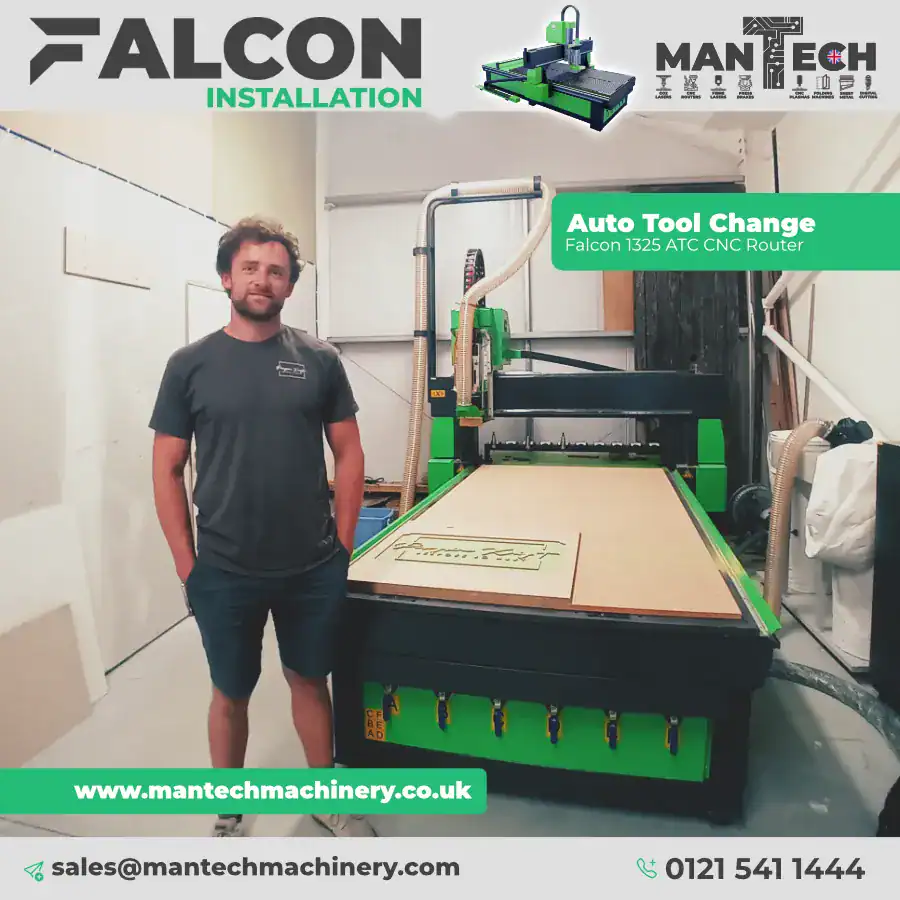

CNC Router Installations - Latest

Spartan 1530 CNC Router Installed in Wakefield

Falcon 1300 x 2500 ATC CNC Router Installed in Chippenham

Falcon 1530 ATC CNC Router Installed for New Sign Maker in Leicester

Apollo 1313 ATC CNC Router Installed in Telford

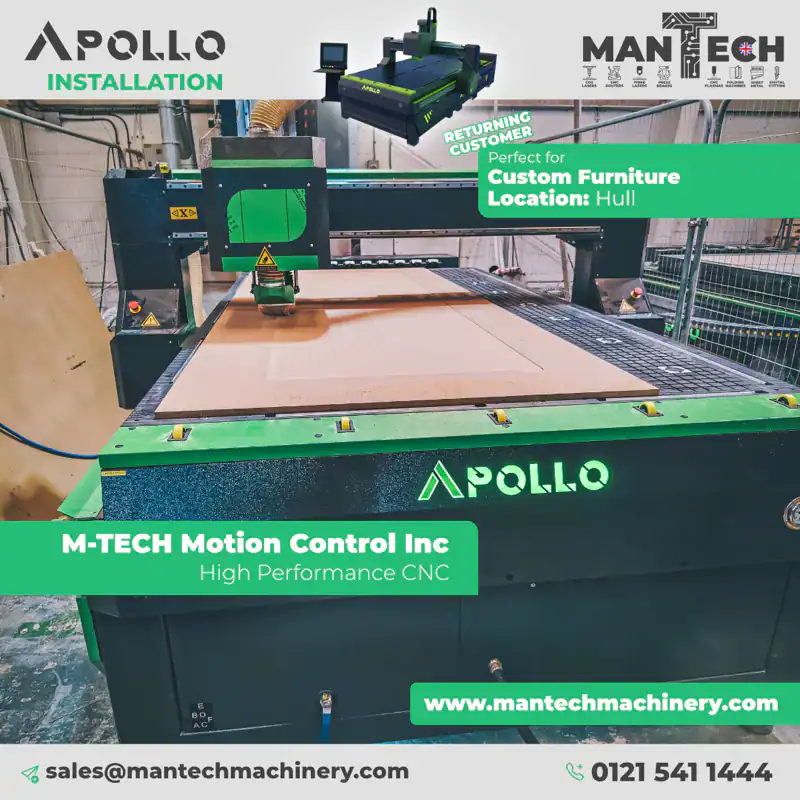

Third Apollo ATC CNC Router Installed for Returning Customer

Falcon ATC CNC Router – New Customer Installation

CNC Routers for Upholstery and Furniture

Falcon ATC 1530 CNC Router Installed for Returning Customer in Dublin

Falcon 1325 ATC CNC Router Installed in Suffolk

Spartan 1313 CNC Router Installed at Belfast School

Falcon 1530 ATC CNC Router Installed in Newcastle