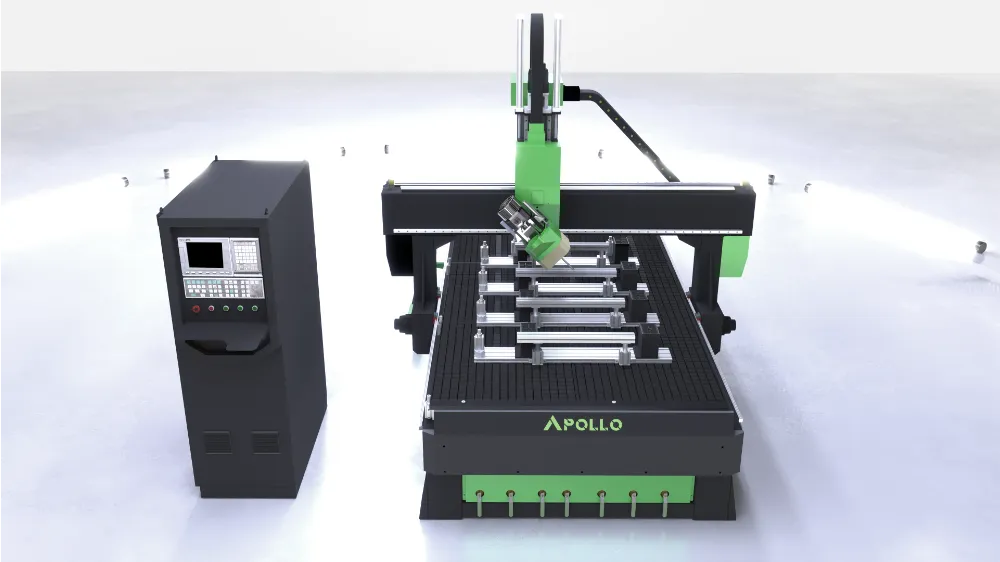

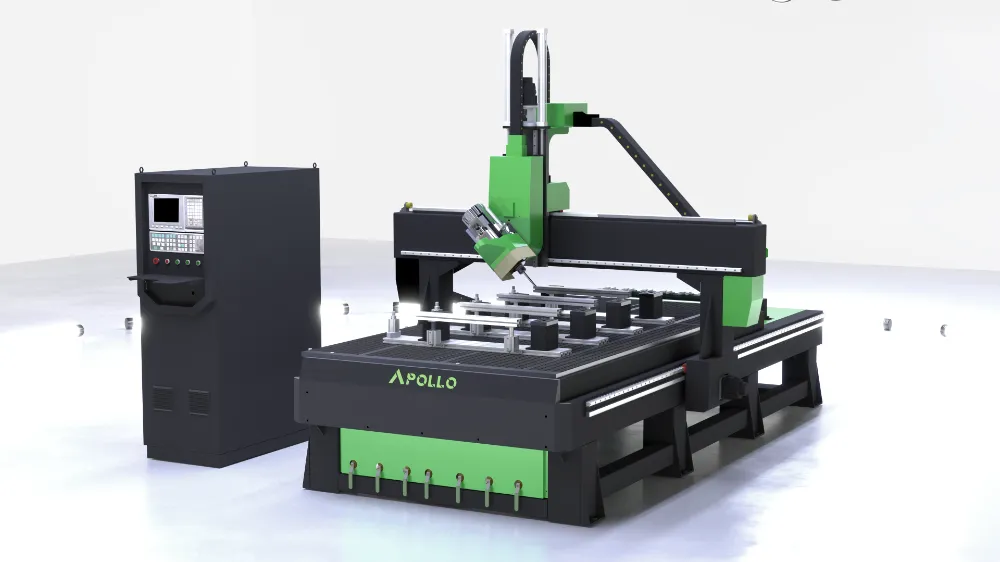

Apollo 4‑Axis ATC CNC Router. Multi-Angled Machining

Advanced Tool Change System

Heavy-Duty Industrial Design

Advanced 4-Axis Capability

Full UK Warranty

Delivery Included

Installation Included

0-180 Degrees of Control

Exceptional Service

Trusted UK Support, Warranty & Training

Explore Our Professional Apollo 4 Axis Tool Change (ATC) CNC Router Machines with Syntec CNC Motion Control

Versatile and Powerful: Impressive 4 Axis CNC Routers with Syntec Control

The Apollo 4 Axis CNC Router is a versatile manufacturing powerhouse, featuring world-renowned Syntec controls and high-quality components. With advanced 4-axis operational capabilities, it’s the perfect solution for industries aiming to achieve exceptional output at a highly competitive price point.

Side view

Front View

Side View

Overview and Features

| Apollo 4 Axis CNC Datasheet | description |

|---|---|

| Table Sizes | Table sizes available: 1300 x 2500 mm / 1600 x 3100 mm / 2050 x 3050 mm / 2050 x 4000 mm |

| Spindle System | 9.0KW (12hp) ER32 air cooled spindle system 24,000rpm with automatic tool change function. 8 x ISO 30 tool holders/positions. |

| Max Z Height Travel | Max Z travel 465mm (without tooling/ material/ spoil board) |

| Mechanical Drive | Helical rack and pinion, reciprocating ball screw drives on Z. |

| Drive System | Yaskawa servo drive system – exceptional performance with lower power consumption |

| Control System | Syntec 4 axis/auto tool change control |

| Linear Guide Rails | HIWIN oil inject centralised linear rail lubrication. |

| Material Positioning Stops | Pneumatic pop-up end stops for material location |

| Vacuum Table Type | Yes - Multi-zone vacuum sytem allows for controlled vacuum areas across the bed, POD and Rail systems for side processing. |

| Tool Cooling System | Integrated pneumatic cutter cooling/lubrication system. |

| Extraction System | Yes included |

| Safety Features | Modular Safety fences with optical IR guarding. |

| Software Package Included | Vectric V-Carve (Fusion 360 Supported) |

| Installation & Training | Our installation team carries out installation and safety training, giving you the confidence to use the machine before they leave. |

| Aftersales | After-sales service is UK based and available to all of our customers if needed. Lifetime technical support via email and telephone. |

| Warranty | All Apollo CNC Routers come with our leading 2 years parts & labour warranty (does not include consumables). |

Why Choose The Apollo 4 Axis CNC Router Range?

Apollo 4 Axis CNC Routers: Versatile Precision for Every Industry

Our Apollo 4 Axis CNC Router range is powered by the world-renowned Syntec control system, which manages all operational functions, including the state-of-the-art 4-axis 9.0kW Auto Tool Change Spindle System. Operators can achieve precise control through the control podium and MPG pendant, while network connectivity allows seamless file transfers for an efficient workflow.

Advanced 4-Axis Functionality

The Apollo 4 Axis CNC Router is engineered to handle both side control and standard 3-axis operations, making it ideal for applications such as:

- Doors

- Frames

- Furniture

Equipped with YASKAWA closed-loop servo motors, it delivers high-speed performance and versatile productivity options, making it the ultimate manufacturing companion.

Built for Industry Demands

The Apollo 4 Axis CNC Router is widely utilised across various sectors, including:

- Furniture Production

- Aerospace

- Marine Engineering

- Automotive

- Prototyping

- Pharmaceutical & Chemical

- Construction

- Educational Institutions

- Custom Product Fabrication

Robust Construction for Long-Term Use

The Apollo features a rigid welded steel box-section frame, heat-treated to eliminate stress before final machining. This ensures years of precise, continuous production with consistent accuracy.

Powerful ATC Spindle System

At the core of the Apollo ATC range is a high-performance air-cooled spindle with a pneumatic clamping system and high spindle speeds, making automatic tool changes and toolpath processing effortless.

Seamless Tool Changing

The Apollo ATC offers a tooling capacity of up to eight tools as standard, with an upgrade option to ten. Tools are stored in a linear rack at the rear of the machine, enabling automatic changes without manual intervention. Set your tool paths and pick-ups in the software, and the Apollo handles the rest, boosting efficiency and reducing downtime.

Why Choose Apollo 4 Axis CNC Routers?

Training and Delivery

All Apollo CNC Routers include delivery and full training. Our expert team ensures you’re confident in using both the machine and its software to produce professional projects with ease.

After-Sales Care

At Mantech, we are committed to delivering affordable machinery coupled with first-class service. Our investment in a highly trained team, efficient processes, and customer support ensures a superior after-sales experience.

- Comprehensive Parts Stock: Our headquarters in Halesowen holds an extensive inventory of parts and spares for rapid turnaround.

- Customer Support: From sales to ongoing care, our team is dedicated to meeting your needs and ensuring the success of your investment.

Key Features at a Glance

- Syntec CNC Motion Control: World-class precision and ease of operation.

- YASKAWA Servo Motors: High-speed performance and repeatability.

- 9.0kW Air-Cooled Spindle: Exceptional toolpath processing and automatic tool change functionality.

- Robust Construction: Heavy-duty frame for longevity and consistent accuracy.

- Customisable Tooling: Standard eight-tool capacity, expandable to ten.

Why Industries Trust the Apollo 4 Axis CNC Router

The Apollo combines advanced technology, robust construction, and unparalleled precision, making it the ideal choice for demanding manufacturing environments. Whether you’re in aerospace, automotive, or furniture production, the Apollo delivers exceptional results every time.

| Wood | Plastics | Composites and other |

|---|---|---|

| Oak | Acrylic | ACM (like Alcubond, Dibond) |

| Birch wood | Polycarbonate | Foamex |

| MFC | Tufnol | Composite Fibreboard |

| Plywood | PVC | Solid Surface (Corian etc) |

| Walnut | Peek | Carbon Fibre |

| Pine | ABS | Graphite |

| Leather | HPDE | Tool Box Foam |

| Redwood | HPL | Laminated Woods |

| OSB board | Yes | Vermiculite Board |

| Cedar | Plexiglass | Trespa |

| Cherry | Nylon | Aluminium |

| Elm | Delrin | Brass |

Compare Our most popular Ranges

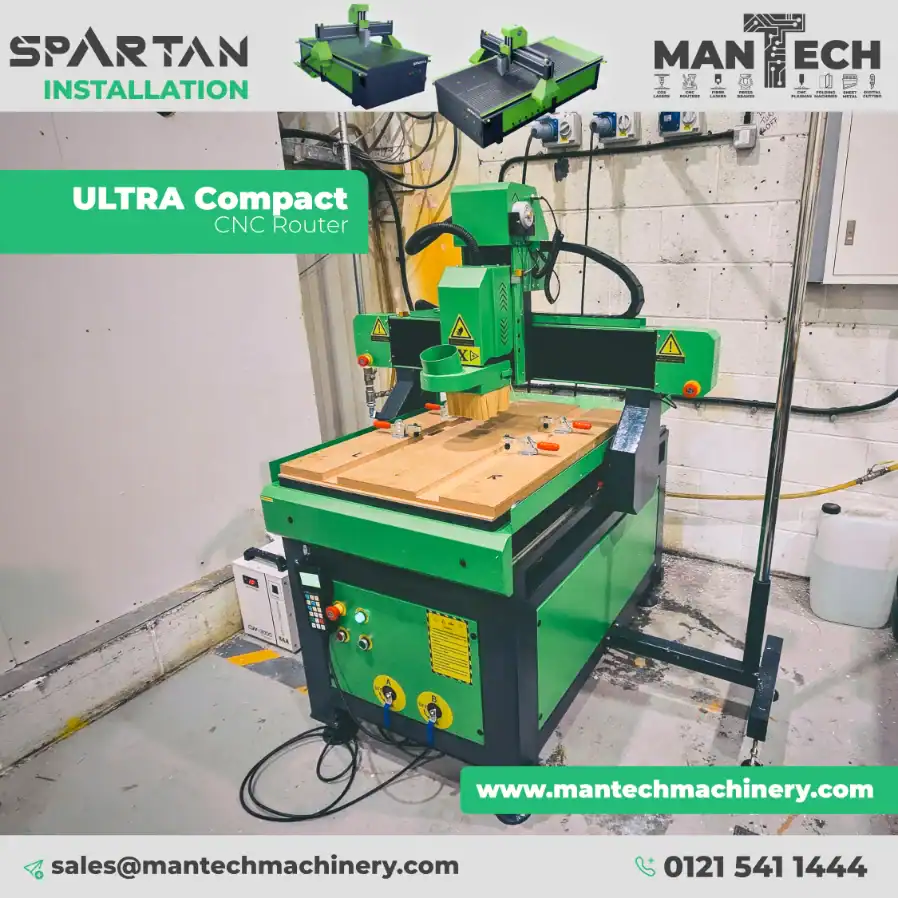

Most Affordable

Spartan CNCExtras: Specialist tooling, MDF/fine dust extraction filters.

Auto Tool Change

Falcon CNCExtras: Specialist tooling, MDF/fine dust extraction filters. Drill bank, oscillating knife system (factory order and runs on Syntec not DSP),

Professional CNC

Apollo CNCExtras: Specialist tooling, MDF/fine dust extraction filters. ATC upgrade.

0-180 degs of Flexibilty

Apollo 4 AxisExtras: Specialist tooling, MDF/fine dust extraction filters.