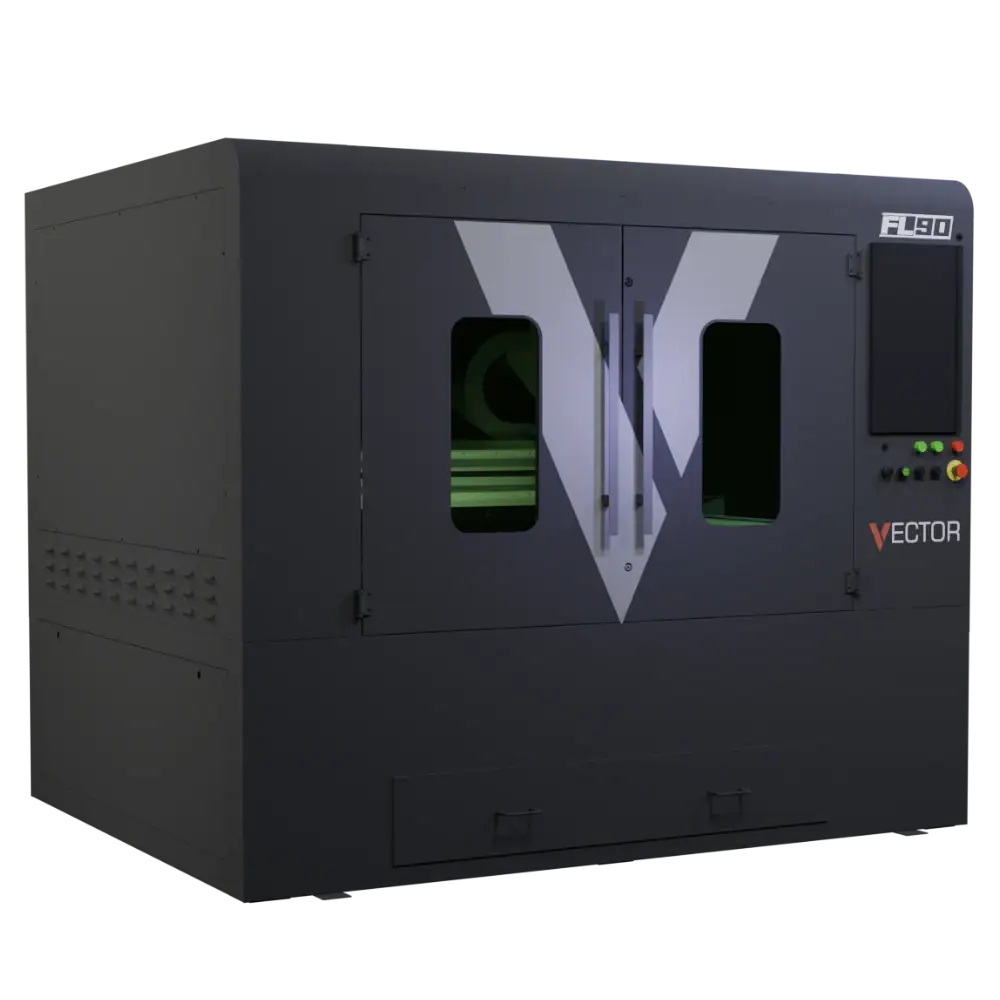

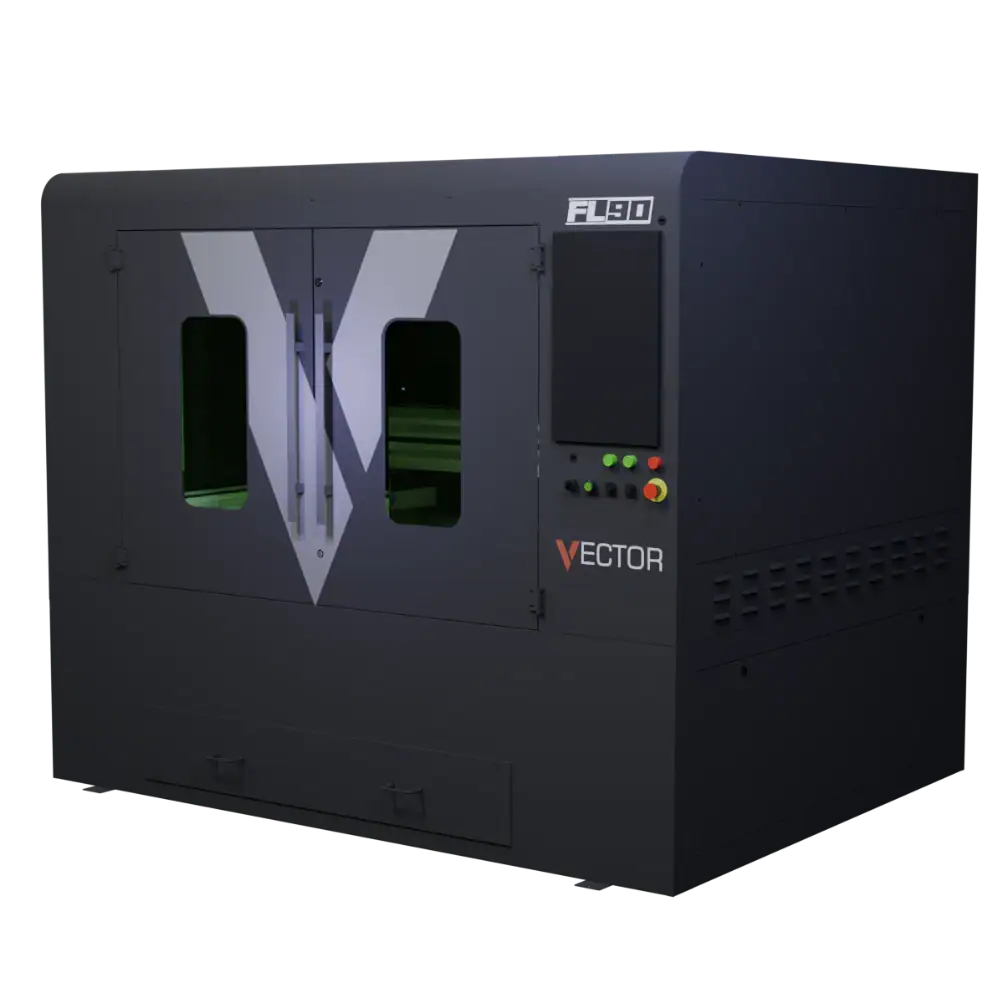

Vector FL90 Fibre Laser Cutter – Compact Industrial Metal Cutting System

Full UK Warranty

Delivery Included

Installation Included

Industrial Compact Design

Exceptional Service

Compact Industrial Fibre Laser with Optimised Cutting Area

UK-Assembled Fibre Laser with V-CUT Control System

Professional Fibre Laser Cutting with V-CAM Software

Compact & High-Performance Vector FL90 Fibre Lasers

Is the Vector FL90 Fibre Laser Right for Your Production?

The Vector FL90 is designed for fabrication businesses that require compact, enclosed fibre laser cutting capability without moving to full-size sheet processing platforms. With a 1300 × 900 mm cutting area and flexible power configurations, the FL90 offers a balanced solution for precision component cutting and medium-gauge sheet fabrication within a controlled footprint.

Key considerations:

-

1300 × 900 mm cutting bed

-

Available in 1.5kW–3kW power configurations

-

Fully enclosed for operator safety

-

UK-developed V-CUT control system

-

Ideal for thin and medium-gauge metal fabrication

Production-Focused Features of the Vector FL90 Fibre Laser

Choose the Right Vector Fibre Laser for Your Workshop

Every Vector fibre laser is UK-assembled and supported by Mantech’s in-house engineering team. Use the guide below to find the model that best matches your space, material size, and production requirements.

Vector FL60

Best for: Entry-level metal cutting & compact workshops

Key Points:

-

Ultra-compact footprint

-

Ideal for education, prototyping & light production

-

Lowest entry cost into fibre laser cutting

Vector FL90

Best for: Small workshops needing more table space

Key Points:

-

1300 × 900mm cutting area

-

More workspace without increasing footprint dramatically

-

Popular upgrade from FL60

Vector FL130

Best for: Growing fabrication businesses

Key Points:

-

Larger 1300 × 1300mm cutting area

-

Better sheet handling

-

Same compact, enclosed design

Vector FL250/300

Best for: Production environments & high throughput

Key Points:

-

Full-size industrial cutting tables

-

Power options up to 12kW

-

Designed for continuous production

Still unsure? Speak to a Vector specialist - we’ll help you choose the right model based on your materials, power requirements and available space.

Talk to a Fibre Laser Specialist

Vector FL90 Fibre Laser – Technical Specifications & Overview

| Specification | Vector FL90 |

|---|---|

| Cutting Area | 1300 × 900 mm low-contact cutting table |

| Laser Power Options | 1.5 kW / 2 kW (single phase) and 1.5–3 kW (three phase) |

| Laser Source | Fibre laser source (configuration dependent) |

| Laser Cutting Head | RayTools autofocus cutting head |

| Control System | UK-developed V-CUT laser cutting control system |

| Software Included Length | V-CUT and V-CAM CAD/CAM suite |

| Servo Drives | High-accuracy servo-driven system |

| Drive System | Double Y-axis ball screw transmission |

| Guide Rails | HIWIN linear guide rails |

| Ball Screw | TBI precision ball screw |

| Safety Enclosure | Fully enclosed laser safety cabin |

| Cooling System | Dual-channel S&A industrial water chiller (power dependent) |

| Consumables Supplied | Protective lens, focus lens, nozzle pack (additional available) |

| Power Requirements | Single phase AC 240 V (1.5–2 kW) or Three phase AC 380 V (3 kW) |

| Installation & Training | Included (UK mainland) |

| Delivery | Included (offloading/positioning available on request) |

| Machine Dimensions (Approx.) | L 2700 mm × D 2000 mm × H 2050 mm |

| Machine Weight (Approx.) | ~1900 kg |

| Chiller Dimensions & Weight | L 550 mm × D 770 mm × H 1030 mm (~95 kg) |

Notes: Laser power configurations up to 3 kW provide capability for mild steel, stainless steel and non-ferrous materials at typical workshop cutting duties. Specifications may vary by configuration and optional equipment – consult our team for application-specific recommendations.

Precision Metal Cutting in a Compact Industrial Format

Important guidance:

Vector Laser Model Selector

Select material, enter thickness and sheet size to get a machine recommendation.

Fibre Laser Installations

Vector FL250 Fibre Laser Cutter Installation – West Yorkshire

New Vector FL250 Fibre Laser Installation – Wokingham (3kW Configuration)

SF3015 3kW Fibre Laser Installation – Wednesbury, West Midlands

Not sure which Fibre Laser model is right for you? Our team can help.