Yes, we offer extended warranties on all of our Fibre Laser Cutters for up to 5 years, providing additional peace of mind and long-term protection for your investment.

Fibre Laser Cutters (Fiber Laser Cutters) for Metal Fabrication (UK)

Flatbed, tube and combo fibre laser systems for sheet, plate and tube — supplied, installed and supported by Mantech’s UK engineering team.

Mantech supplies a comprehensive range of industrial fibre (fiber) laser cutting machines for manufacturers demanding speed, accuracy and reliability. From entry-level systems to high-power flatbed, tube and combination fibre lasers, we help UK businesses increase throughput, consistency and cutting efficiency.

Our fibre laser cutter range includes the Vector FL60, FL90, FL130 and high-power FL250 / FL300 systems, alongside specialist flatbed and tube laser solutions

Get a Fibre Laser Cutter Quote

Compare Fibre Laser CuttersInstalled, supported and serviced by ManTech Machinery engineers across the UK

Reliable Delivery Across the UK & Ireland

We provide dependable delivery and optional off-loading services for all fibre laser cutter systems. Whether compact or oversized, your machine is handled safely and positioned exactly where you need it.

Installed by Certified Laser Engineers

Our in-house engineers handle every installation, ensuring your CNC laser cutter is calibrated, tested and production-ready before we hand it over. No subcontractors, no guesswork, just expert setup.

Simple Software, Powerful Cutting Results

Every system includes easy-to-use laser cutting software such as CypCut or V-CAM/CUT, making file preparation, nesting and production smooth, even for first-time laser operators.

Learn about V-Cam and V-CUTHands-On Operator Training Included

We provide full operator training covering setup, safety, workflow and best-practice cutting techniques. Additional training sessions can be arranged as your team grows.

Extraction & Filtration Options for Compliance

We supply fume extraction units, filtration systems and pipework to keep your workspace safe and compliant with local regulations.

Backed by Real Support

Enjoy a 2-year warranty on most fibre lasers plus lifetime UK-based technical support. Speak directly with an engineer, never a call centre.

Why Choose ManTech For Fibre Laser Cutters?

At Mantech, we supply industry-proven fibre laser cutters that deliver performance, reliability, and value. Our machines are trusted by UK manufacturers and fabricators for their precision, ease of use, and expert backup. With in-house support and over 25 years of experience, we’re here to help you make the most of your metal cutting machines — from purchase to production.

Competitive Prices on Fibre Laser Cutters

We offer a wide range of fibre laser cutting machines at highly competitive prices. Whether you're a small business or scaling production, our solutions provide an affordable route into high-precision metal cutting. Finance options are also available.

Delivery Included – Offloading Support Available

Every fibre laser cutter includes standard UK delivery. Need help with offloading and siting? We can assist with that too. Our team offers optional support and guidance to make sure your machine installation runs smoothly.

Operator Training Included – Additional Support Available

Each system comes with comprehensive operator training as standard. If you need more training in the future — for new team members or advanced techniques — we’re just a call away.

Reliable Aftercare from Experienced Engineers

Our in-house service desk and field engineers provide fast, effective support across the UK. Whether you need maintenance, technical advice or spare parts, we’re here to keep your machine performing at its best.

Advanced Cutting Software Built In

All machines include powerful cutting software with features like nesting, fly-cutting, and edge-seek detection. These tools help you cut more efficiently and reduce waste, whether you’re handling mild steel, stainless, or aluminium.

Professional Installation for a Quick Start

All Mantech fibre lasers come with professional installation by our in-house engineers. We'll ensure everything is connected and calibrated correctly so you can start cutting with confidence — fast.

UK Engineering and Support Teams

Our support and engineering teams are based at our West Midlands HQ. You’ll benefit from fast response times and direct contact with experts who know your fibre laser machine inside and out.

Over 25 Years in British Manufacturing

With more than two decades of experience in supplying industrial cutting equipment, we’ve built a solid reputation for dependable machines and honest, practical support.

Your Trusted Partner for Fibre Laser Cutting Solutions

-

Proven Experience – decades supplying and supporting industrial machinery across the UK & Ireland

-

Reliable Performance – machines selected for durability, accuracy, and long-term operation

-

Long-Term Support – installation, training, service, and spares support throughout the machine lifecycle

Our Recommended Fibre Laser Cutters

Mantech Machinery UK offers a curated selection of high-quality fibre laser cutting machines to suit diverse business needs and budgets. Browse our range belowExplore our range below and discover how Mantech Machinery can provide the perfect fibre laser cutting solution to meet your specific needs.

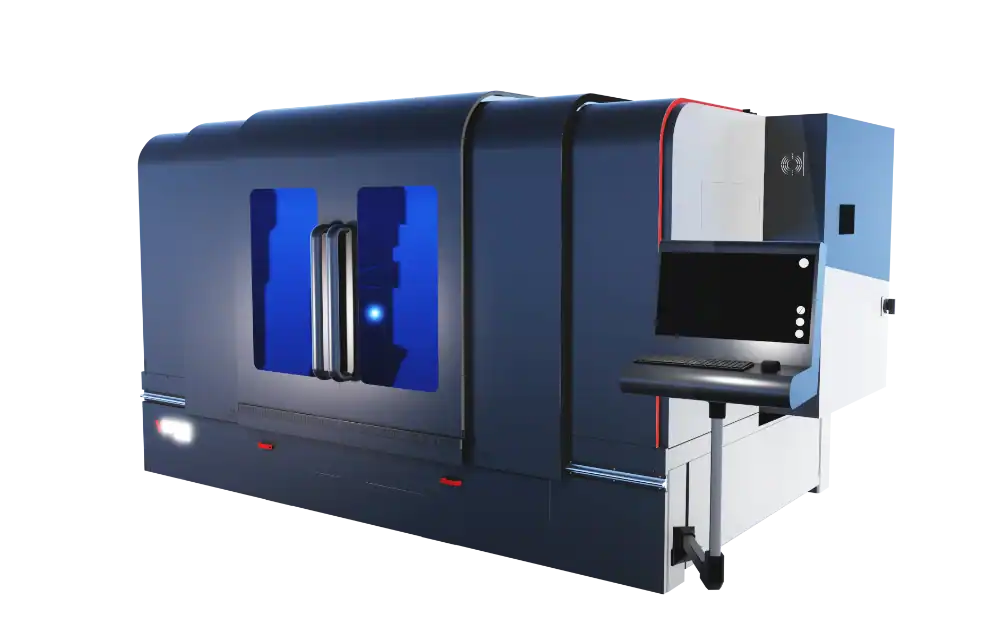

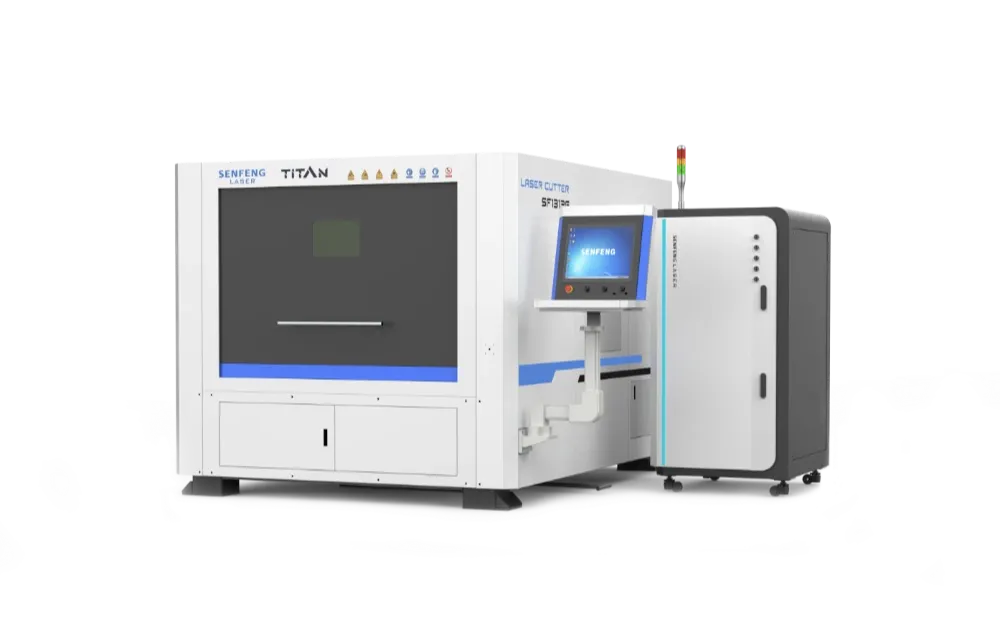

Vector FL60 Fibre Laser

The FL60 is a compact fibre laser designed for precision metal cutting in tight workspaces. With a 600 × 600 mm bed size and enclosed design, it’s ideal for smaller workshops, schools, and businesses needing accurate, clean cuts on mild steel, stainless, and other thin metals.

Built for ease of use and low running costs, the FL60 offers professional performance without the industrial footprint — a smart choice for anyone starting out or scaling down.

Perfect for: Light metal fabrication, signage, R&D, education

Key advantage: Compact size without compromising cut quality

Vector FL90 Fibre Laser

The FL90 is a space-saving fibre laser with a larger 1300 × 900 mm cutting area — ideal for workshops needing more flexibility without stepping up to full-size systems. With available power options up to 3 kW, it’s built to handle mild steel, stainless and non-ferrous sheet work with consistent accuracy. Its compact frame, front access, and simple controls make it a strong choice for growing manufacturers looking to boost productivity in a smaller footprint.

Perfect for: Sheet metal, fabrication, signage, light manufacturing

Key advantage: Larger bed size with compact machine format

Vector FL130 Fibre Laser

With a larger 1300 × 1300 mm cutting area, the FL130 offers more flexibility while keeping the compact, enclosed format that suits tighter workshop spaces. It's ideal for cutting mild steel, stainless and other metals at higher throughput, with power options to match your workflow. This model builds on the strengths of the FL90, giving you extra table capacity without stepping up to a full industrial footprint — a solid upgrade for growing shops.

Perfect for: Multi-sheet workflows, fabrication, batch cutting

Perfect for: Multi-sheet workflows, fabrication, batch cutting

Key advantage: Larger table, same compact format

Vector FL250/300 Range

For jobs that need a larger working area and more laser power, the FL250 and FL300 deliver industrial-grade performance without overcomplicating your setup. With bed sizes of 1260 × 2510 mm (FL250) and 1500 × 3000 mm (FL300 Plus), these models are built to handle bigger sheet formats and heavier workloads. Ideal for fabrication shops running daily production, this range balances cutting speed, precision and reliability in a proven, ready-to-run format.

Perfect for: High-volume sheet cutting, fabrication, subcontract work

Perfect for: High-volume sheet cutting, fabrication, subcontract work

Key advantage: Bigger beds + more power for serious production

Specialist Fibre Laser Cutting Machines for Advanced Applications

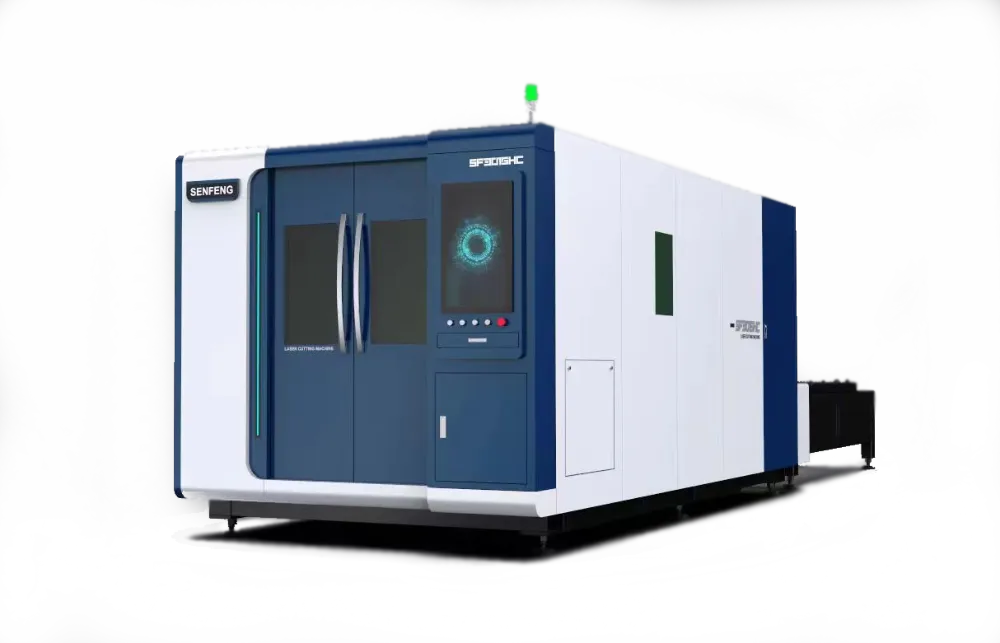

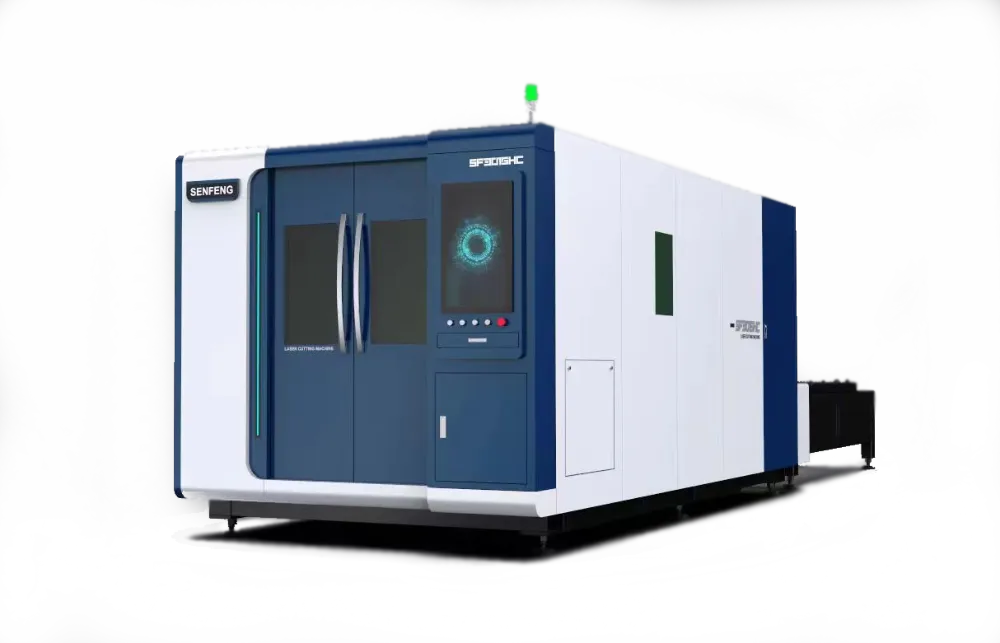

SF Medium Powered Fibre Laser Cutters

This mid-range fibre laser offers excellent value for manufacturers who need more power and flexibility than entry-level models. With available bed sizes to suit standard sheet formats and laser powers ideal for mild steel, stainless, and aluminium, it’s a strong fit for general fabrication. Enclosed for safety and built for daily use, the SF Medium Powered series delivers dependable performance in a well-balanced package.

Perfect for: Fabricators, general engineering, workshop upgrades

Perfect for: Fabricators, general engineering, workshop upgrades

Key advantage: Solid performance at a mid-range price point

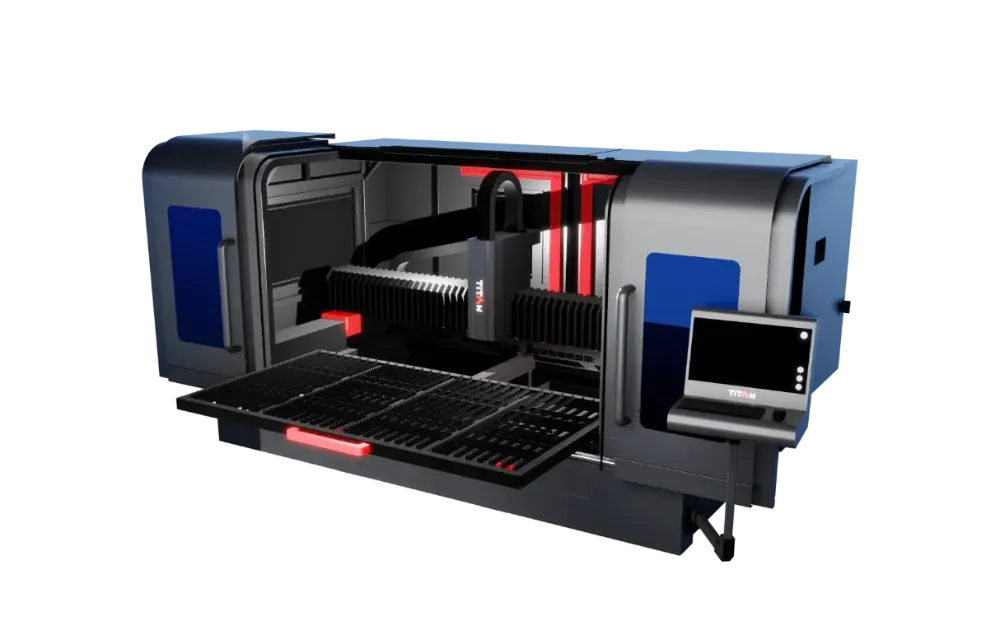

SF High Powered Fibre Laser Cutters

Built for demanding production, the SF High Power series offers cutting performance from 6 kW up to 30 kW — ideal for thick materials and high-speed workflows. Each system includes dual shuttle tables for rapid material changeover, plus industrial enclosures for safety and noise reduction. Whether you’re cutting large batches of mild steel or processing thicker stainless, this series delivers speed, accuracy and uptime for serious output.

Perfect for: Steel centres, OEMs, heavy fabrication

Perfect for: Steel centres, OEMs, heavy fabrication

Key advantage: Power + throughput for industrial-scale cutting

SF Ultra High Powered Fibre Laser Cutters

Designed for top-tier production, this 5th Gen fibre laser system offers extreme performance with power options up to 60 kW and bed lengths reaching 12.1 m. Whether you’re cutting thick mild steel, stainless, or handling oversized formats, this machine delivers serious throughput without compromise. It features shuttle table automation for nonstop workflow — ideal for high-volume, multi-shift environments where time, accuracy and consistency matter.

Perfect for: Steel service centres, large-scale processing, OEMs

Perfect for: Steel service centres, large-scale processing, OEMs

Key advantage: Ultra power + extended bed for heavy-duty output

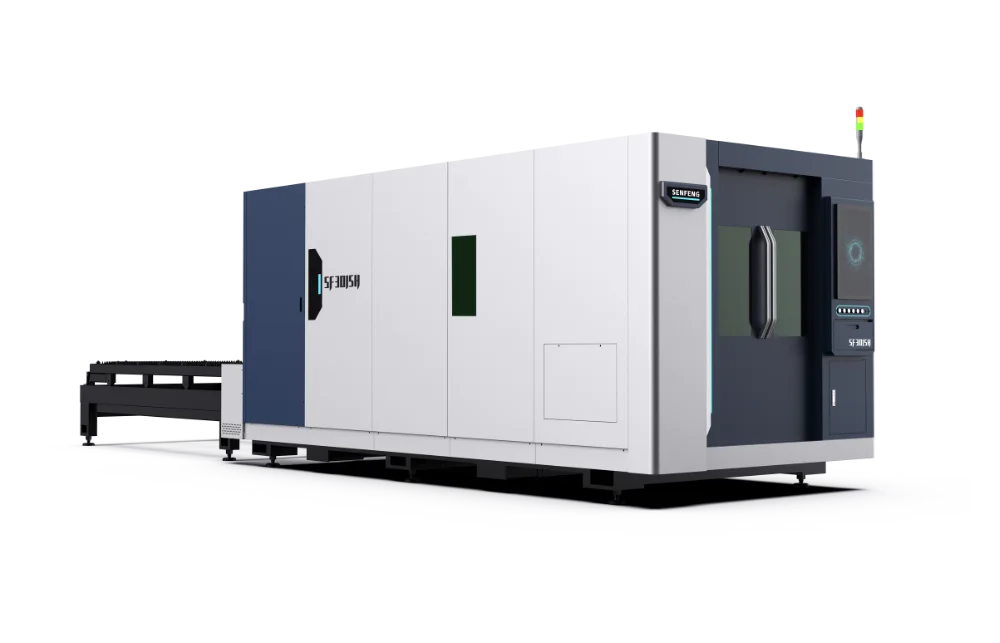

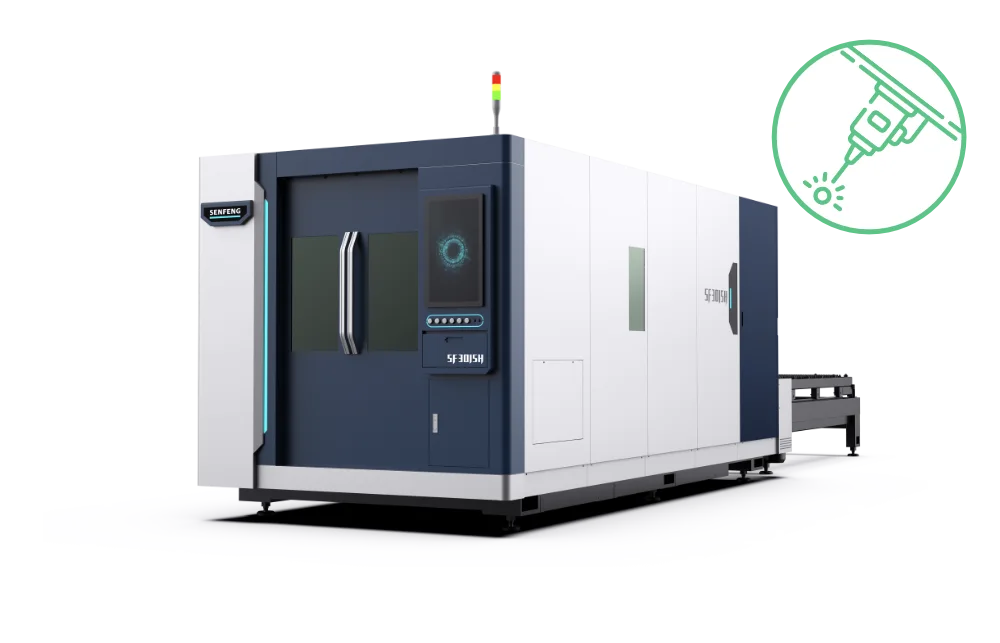

SF Bevel Cut Fibre Laser Cutters

The SF3015H brings precision bevel cutting to fibre laser workflows, offering 0–45° angled cuts for chamfered edges, weld prep, and advanced profiling. With a fully enclosed build for operator safety and a shuttle table for fast material changeover, this system is built for busy fabrication environments. It's the ideal tool for shops that want bevel capability without separate processing steps or secondary operations.

Perfect for: Fabricators, steelwork, prep-for-weld applications

Perfect for: Fabricators, steelwork, prep-for-weld applications

Key advantage: Built-in bevel cutting with enclosed safety & speed

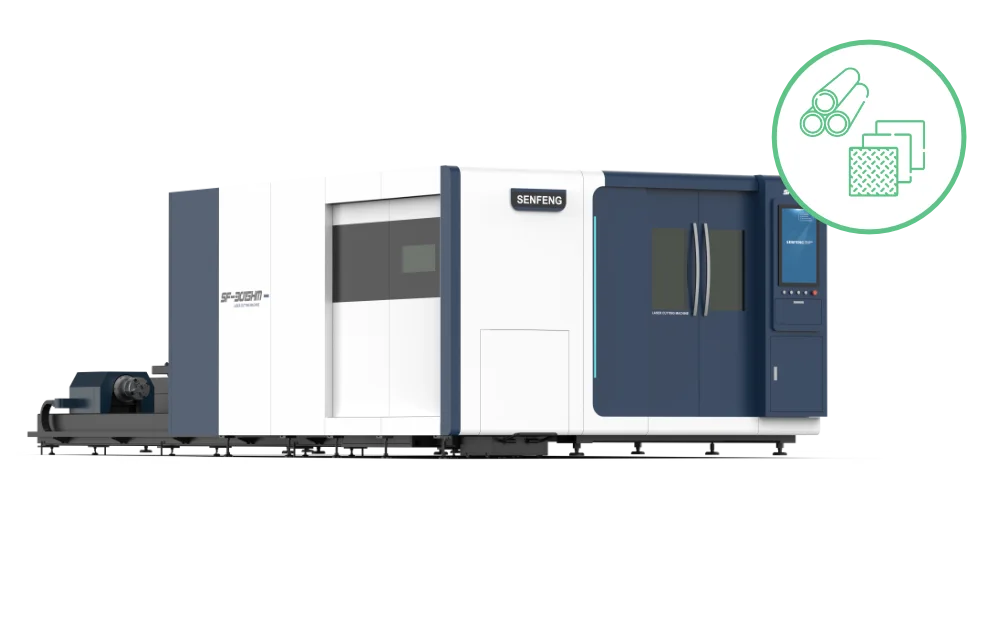

SF Combination Fibre Laser Cutters

The SF3015HM offers true dual-function capability — flat sheet cutting and integrated tube processing in one compact footprint. It’s ideal for manufacturers who need versatility without adding multiple machines. This system allows seamless switching between profiles and plate work, saving time, floor space, and cost. Fully enclosed and built for production, it brings flexibility to shops handling mixed metal fabrication.

Perfect for: Mixed production, metalwork contractors, space-limited workshops

Perfect for: Mixed production, metalwork contractors, space-limited workshops

Key advantage: One machine for both flatbed and tube cutting

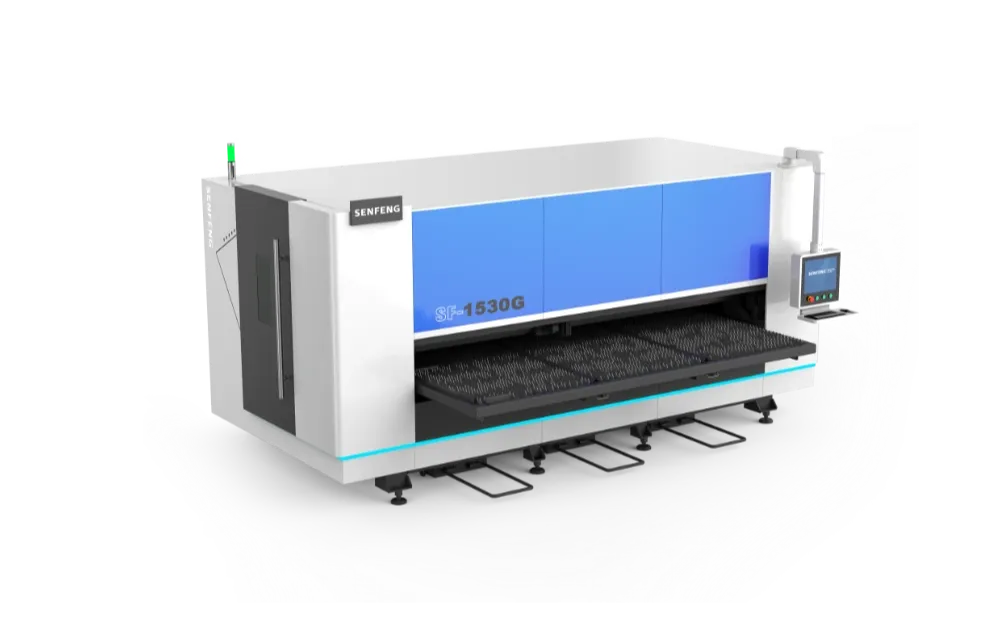

SF Single Table Fibre Laser Cutters

The SF1530G Fibre Laser is designed for workshops that don’t need an exchange shuttle system, offering a clean, efficient solution with a smaller footprint. With a full-sized 1530 x 3050 mm cutting bed and power options from 1kW to 3kW, it delivers precision, consistency, and reliability across a range of light to medium-duty metal cutting jobs. Ideal for businesses looking to maximise space while retaining productivity.

Perfect for: Small-to-medium workshops, budget-conscious upgrades

Key advantage: Full-sized cutting on a single table setup

SF Compact Fibre Laser Cutters

The SF1313G Fibre Laser is the ideal space-saving solution for smaller workshops that still demand serious cutting performance. With a 1300 x 1300 mm bed and power options ranging from 1.5kW to 3kW, this model delivers efficient, accurate results while taking up minimal floor space. It’s a smart choice for businesses needing flexibility, reliability, and compact precision cutting.

Perfect for: Small businesses, tight workshops, entry-level metal cutting

Key advantage: Full-featured power in a minimal footprint

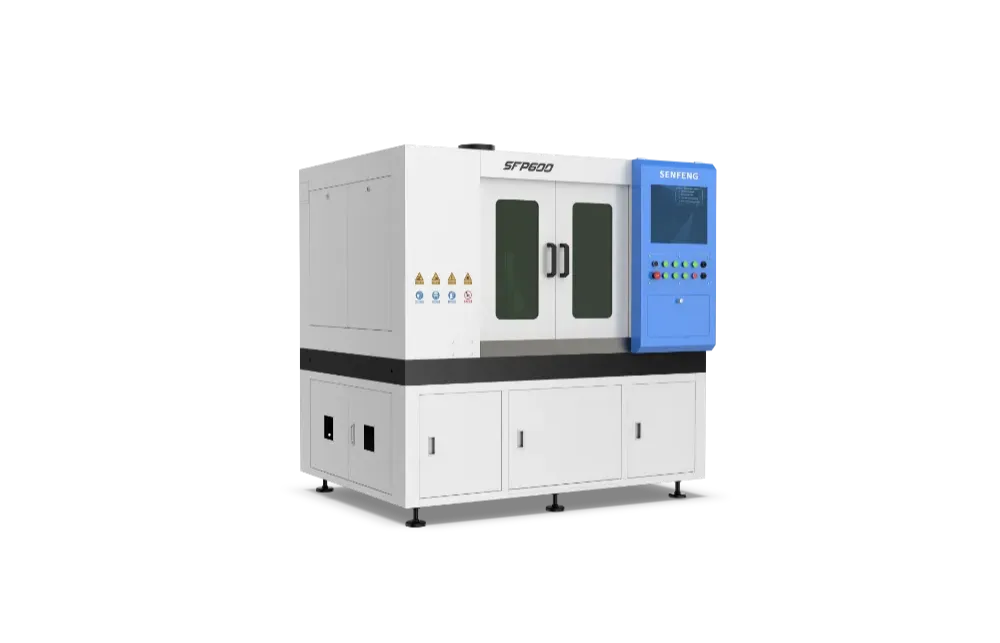

SF Ultra Compact Fibre Laser Cutters

The SF6060 Fibre Laser is our most compact metal cutting system, built for high-precision work on thin sheets from 0.2mm to 5mm. With a 600 x 600 mm bed and power options between 1.5kW and 3kW, it’s a reliable choice for smaller operations needing efficient and accurate results. Ideal for prototyping, light production, or compact workshops where every millimetre counts.

Perfect for: Light metalwork, small-scale production, tight spaces

Key advantage: Space-saving design with professional-grade performance

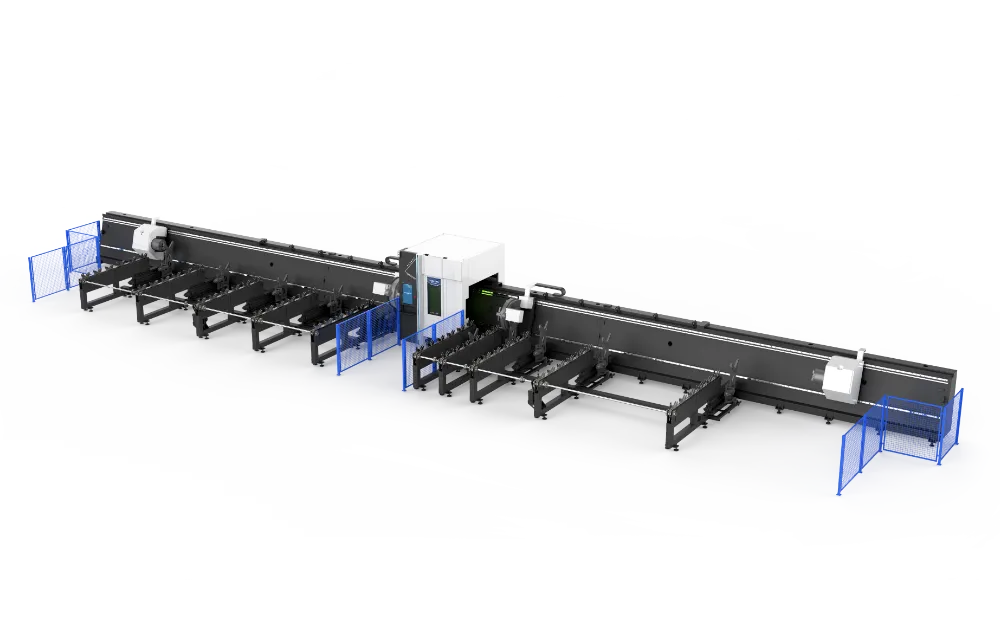

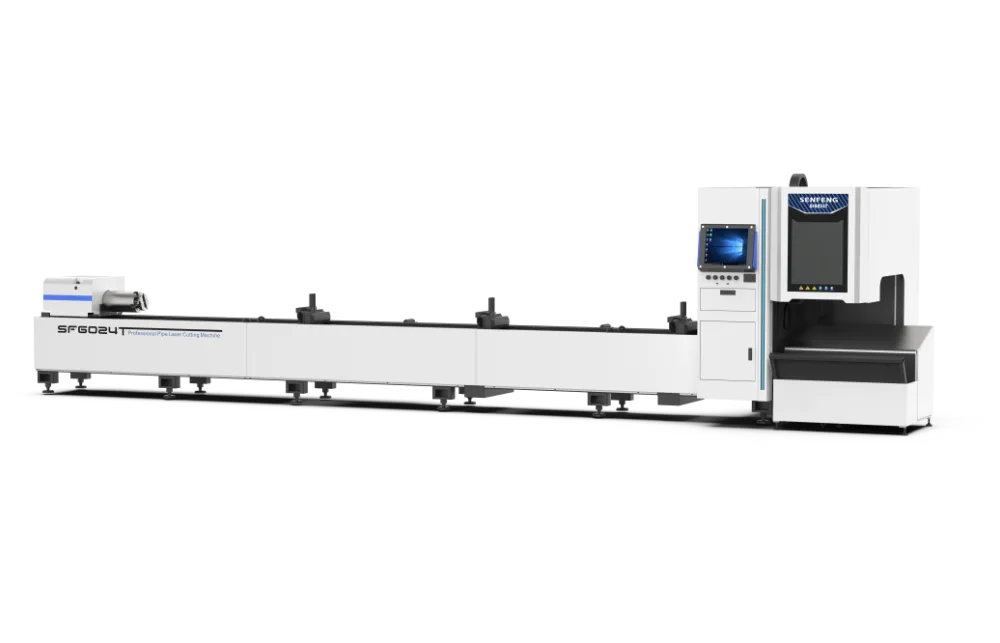

SF Ultra Heavy X4 Chuck Tube Fibre Laser Cutters

The SF12050HT is engineered for ultra-heavy tube and profile cutting, featuring a vertically mounted rail system for enhanced stability and precision. With laser power options from 4kW to 12kW, it can process round tubes from 50mm to 500mm in diameter, making it the ideal solution for large-scale industrial applications.

SF12050HT Ultra Heavy-Duty Tube Laser – Precision Cutting for Large Profiles

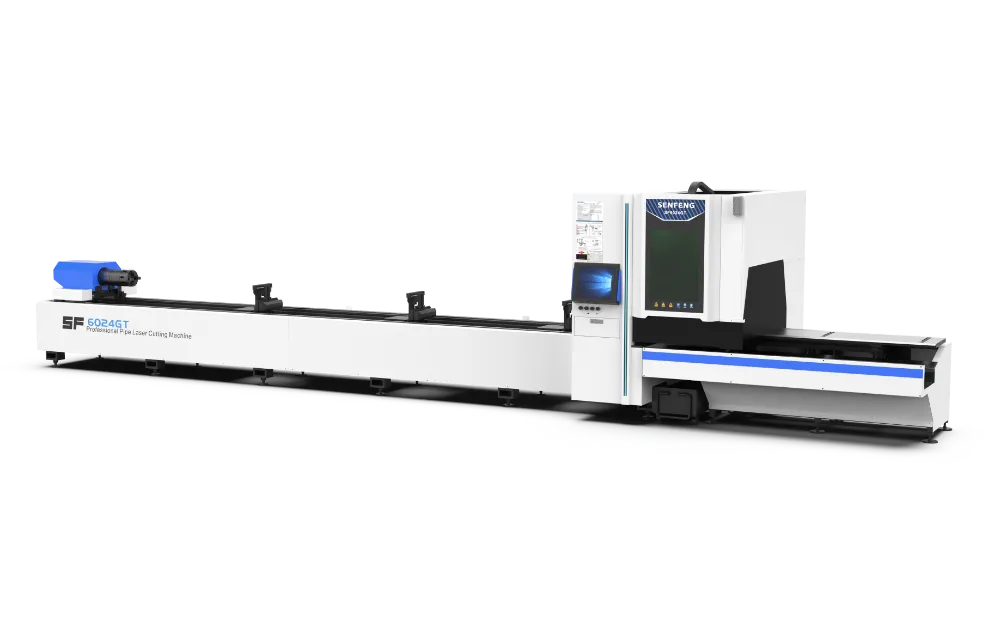

SF X3 Chuck Tube Fibre Laser Cutters

Designed for larger material lengths, this 3-chuck system is available in 6m and 12m models, supporting 240mm and 350mm diameters. Capable of cutting round, square, rectangular, L, U, and H-shaped profiles, it ensures maximum material utilisation with zero tailing, making it a high-efficiency solution for industrial tube processing.

Advanced 3-Chuck Tube Laser – High-Capacity, Zero Tailing Cutting

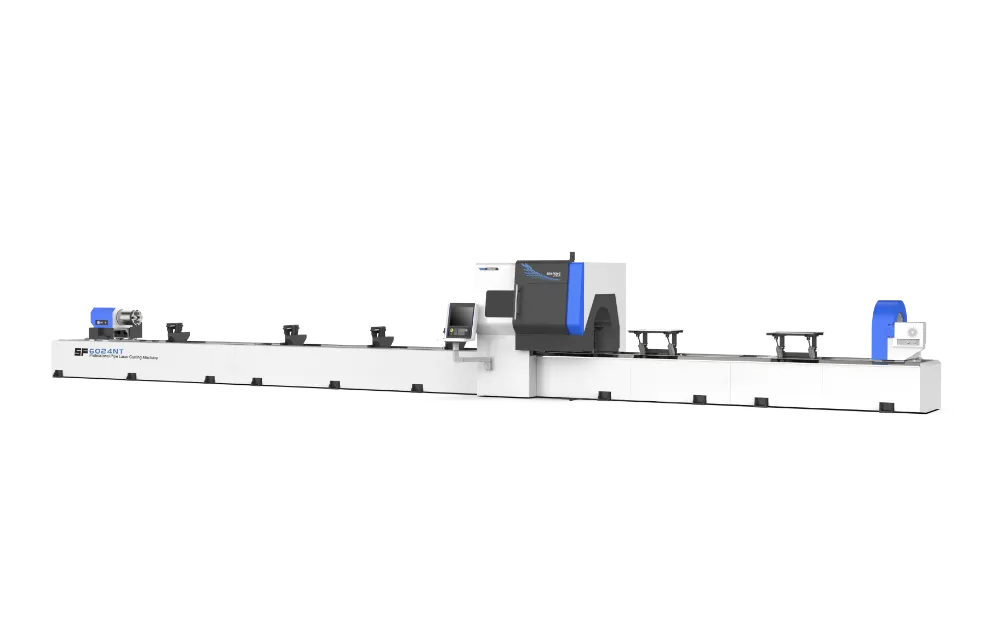

SF X2 Chuck 6m Tube Fibre Laser Cutters

With an outer diameter capacity of up to 220mm and a maximum processing length of 6m, the SF6000 range is ideal for various industrial applications. For enhanced automation, it can be configured with auto-load and unload options, offering increased efficiency and versatility in tube and profile cutting.

SF6000 Tube Laser – Versatile & High-Capacity Cutting Solution

SF Bevel Cut Tube Fibre Laser Cutters

Our tube lasers feature powerful 45° bevel cutting capabilities, expanding production versatility and precision. Available with laser power sources ranging from 3kW to 6kW, this system ensures high-quality cuts and improved processing efficiency for a wide range of tube and profile applications.

Advanced 45° Bevel Cutting – Enhanced Tube Laser Performance

What our fibre laser cutters are typically used to cut

Mild Steel

All of our fibre laser cutters are designed for cutting mild and carbon steel efficiently, with achievable thickness dependent on laser power, cutting head, and gas selection.

Stainless Steel

Fibre lasers excel at high-accuracy stainless steel cutting, producing clean edges and consistent results across a wide range of thicknesses.

Aluminium

Aluminium can be cut reliably on a fibre laser with the correct machine configuration and parameters. Our engineers can advise on the best setup for this highly reflective material.

Brass

Brass is a highly reflective metal and requires suitable cutting head protection and carefully controlled parameters to be processed safely and effectively on a fibre laser.

Copper

Copper is also highly reflective and, like brass, requires appropriate cutting head protection and precise parameter control for safe and consistent fibre laser cutting.

Titanium

Titanium can be cut efficiently on a fibre laser using appropriate assist gases and optimised cutting parameters, making it suitable for specialist and aerospace applications.

Cutting thickness and performance depend on laser power and machine specification - see our model comparison below.

Where Fibre Laser Cutters Are Used

Fibre laser cutters are widely used across manufacturing and fabrication environments where accuracy, speed, and repeatability are critical. Below are some of the most common applications we see across UK businesses.

General Fabrication & Sheet Metal

In manufacturing and engineering environments, fibre lasers are valued for their speed, consistency, and ability to integrate into streamlined production workflows, helping reduce cycle times and operating costs.

Manufacturing & Engineering

In manufacturing and engineering environments, fibre lasers are valued for their speed, consistency, and ability to integrate into streamlined production workflows, helping reduce cycle times and operating costs.

Automotive & Subcontract Cutting

Automotive suppliers and subcontract cutting businesses use fibre laser cutters to deliver high-quality parts at scale, meeting tight tolerances and fast turnaround requirements.

Aerospace & Precision Components

Fibre lasers are used in aerospace and precision engineering applications where fine detail, clean edges, and controlled cutting parameters are essential for specialist metal components.

Enclosures, Panels & Electrical Cabinets

Fibre laser cutters are well suited to producing enclosures, panels, and electrical cabinets, offering clean cut quality and repeatability for both bespoke and standardised designs.

Specialist & Custom Manufacturing

In specialist manufacturing environments, fibre laser cutters provide the flexibility to process a wide range of metal components efficiently, supporting custom, low-volume, or evolving production requirements.

Many of our fibre laser installations are in fabrication and manufacturing businesses across the UK, supporting day-to-day production cutting.

Choosing the Right Fibre Laser for Your Business

Selecting the right fibre laser cutter depends on your materials, production volume, available space, and future growth plans. Below is a simple guide to help you identify the most suitable fibre laser solution for your business.

Who it’s for: Ideal for small workshops, start-ups, and businesses bringing laser cutting in-house for the first time.

Typical requirements

-

Mild steel, stainless steel, aluminium

-

Lower to mid-range thicknesses

-

Flexible job types

-

Compact footprint

Recommended fibre laser: Vector FL60 / FL90 Fibre Laser Cutters

Why: These machines offer reliable cutting performance, manageable operating costs, and a compact design, making them well suited to workshops with limited space or evolving production needs.

View Vector FL60 & Vector FL90 Fibre Lasers →

Who it’s for: Designed for growing manufacturers and fabrication businesses with increasing throughput requirements.

Typical requirements

- Daily production cutting

- Mixed material thicknesses

- Improved cycle times

- Scalable solution

Recommended fibre laser: Vector FL130 Fibre Laser Cutter

Why:The Vector FL130 provides a strong balance between cutting power, speed, and versatility, making it suitable for businesses moving from job-based cutting to more structured production workflows.

Who it’s for: Best suited to high-volume production environments where speed, consistency, and uptime are critical.

Typical requirements

-

Thicker materials

-

Continuous operation

-

Automated workflows

-

High output expectations

Recommended fibre laser: Vector FL250 / 300 Fibre Laser Cutters

Why: These machines are engineered for demanding production environments, offering higher power options, larger cutting areas, and the performance required to support long production runs.

Who it’s for: Suitable for businesses with restricted floor space or specialist site constraints.

Typical requirements

- Compact machine layout

- Efficient workflow design

- Flexible installation options

Recommended fibre laser: Compact Vector Fibre Laser Configurations

Why: With carefully planned machine layouts and configuration options, fibre laser systems can be installed efficiently even in space-limited environments without compromising cutting performance.

Speak to an Engineer About Your Space →

Our team regularly supports customers through machine selection, site planning, installation, and long-term service, ensuring each fibre laser solution is matched to real-world production requirements.

Fibre Laser Cutter Model Comparison

Compare our fibre laser cutter range below to identify the most suitable machine based on cutting area, power options, and production requirements.

Model | Cutting Area | Power Options | Typical Materials | Ideal For | |

Vector FL60 Entry Level | Compact Formats | 1.5-3 kW | Mild steel. stainless steel, aluminium | Small workkshops, first time fibre laser users | |

Vector FL90 Compact production | Compact / medium formats | 1.5-3 kW | Mild steel. stainless steel, aluminium | Growing workshops with regular cutting demand | |

Vector FL130 Production balance | Large formats | 1.5-3 kW | Mild steel. stainless steel, aluminium | Fabrication & manufacturing environments | |

Vector FL250 / FL300 High throughput | Extra large formats | 1.5-12 kW | Mild steel. stainless steel, aluminium | Higher volume production & manufacturing |

Cutting performance and maximum thickness depend on laser power, material type, and machine configuration. Reflective metals such as brass and copper require suitable cutting head protection.

Other Fibre Laser Options

Model | Cutting Area | Power Options | Best Suited For | |

SF Medium Powered Fibre Laser Cutters | Standard formats | 1.5-6kW | General fabrication, workshop upgrades | |

SF High Powered Fibre Laser Cutters | Large sheet formats | 6-30 kW | Production environments, thicker materials | |

SF ULtra High Powered Fibre Lasers | Extra large formats | upto 60 kW | Heavy-duty, high-volume production |

These options are typically selected where higher power, larger formats, or specific budget requirements apply.

Your FAQs Answered

Get in touch If you can't find what you're looking for, contact us.

How much does a fibre laser cutter cost?

The cost of a fibre laser cutter varies significantly depending on factors like laser power, work area size, automation features, and manufacturer. Entry-level machines can start from around £20K, while high-power, fully automated industrial fibre laser cutters can reach 200K plus. For accurate pricing tailored to your specific requirements, we encourage you to:

What maintenance is required for a fibre laser cutter?

Fibre laser cutters generally require less maintenance than CO2 lasers, but regular upkeep is still important. Key maintenance tasks include: cleaning optics, inspecting and cleaning the cutting head, checking coolant levels, lubricating moving parts, and replacing consumables as needed. Mantech Machinery offers preventative maintenance programmes to help you keep your machine in optimal condition.

What materials can a fibre laser cutter cut?

Fibre laser cutters are highly versatile and can cut a wide range of metals, including mild steel, stainless steel, aluminium, copper, brass, titanium, and more. The maximum thickness achievable depends on the laser power and material type.

Contact us to discuss your specific material-cutting needs, and our experts can advise on the appropriate machine and power level.

Does the Fibre Laser Come with Software?

Yes, all of our Fibre Laser Cutters come with integrated software and a built-in PC system for full machine control.

- FL 60/90/130 models – Supplied with a UK-designed fibre laser control system.

- FL250/300 models – Will feature this system following successful beta testing.

- SF models – Equipped with CypCut, CypTube, or HypTube, depending on the model.

If you have specific software requirements or prior experience, our friendly fibre laser sales engineers are happy to assist in finding the best solution for your needs.

What Warranty Do You Offer with Your Fibre Laser Cutters?

All of our Fibre Laser Cutters come with a comprehensive 2-year warranty as standard.

Additionally, we provide lifetime technical support via telephone and email, ensuring you have ongoing access to expert assistance whenever you need it.

Do You Offer Extended Warranties?

Does Mantech Offer Service Agreements?

Yes, we provide customisable service-level agreements (SLAs) to support your Fibre Laser Cutter.

- Available at the time of purchase or anytime afterwards.

- Ensures ongoing maintenance, priority support, and optimal machine performance.

- Contact your Mantech representative or our service team for more details.

Do you have your own engineering team?

All of our engineers are employed by Mantech. We have a large network of road engineers that support our customers throughout the UK, Ireland and Europe.

Advanced Fibre Laser Software Features

All fibre laser cutters supplied by ManTech Machinery are equipped with advanced control software designed for efficient, accurate, and reliable production cutting. These systems support streamlined workflows, material optimisation, and consistent cut quality across a wide range of applications.

Comprehensive Software

Package

Seamless System

Integration

Advanced

Feature Set

User-Friendly Operation

Intuitive CNC control interfaces designed for efficient programming and daily operation.

Material Optimisation (Nesting)

Optimised nesting functions help reduce material waste and improve cutting efficiency.

Smart Parts Library

Easily manage and reuse standard components for faster setup and repeatable production.

Precision Cutting Compensation

Automatic compensation ensures consistent accuracy across varying material thicknesses.

Efficient Edge Cutting (Common)

Reduces cutting time on shared edges for improved productivity in batch production.

Automated Gas Control

Intelligent gas management supports clean cuts, stable performance, and efficient operation.

*Software features and capabilities may vary by model and specification - our team can advise on the most suitable configuration for your application.

Supporting Equipment for Fibre Laser Cutting

Fibre laser cutting systems rely on correctly specified supporting equipment to maintain safe operation, protect machine components, and ensure consistent cutting performance. This includes extraction systems, compressed air supply, and other integrated utilities essential to reliable production environments.

Key Supporting Systems for Fibre Laser Cutting

Fume & Dust Extraction Systems

-

Removes fumes and fine metal particulates generated during cutting

-

Supports operator safety and workplace compliance

-

Helps protect sensitive machine components and optics

Compressed Air for Fibre Laser Cutting

-

Provides stable assist air for mild steel cutting

-

Supports cutting head operation and optics protection

-

Systems specified to suit laser power and duty cycle

Specification & Integration Support

-

Guidance on selecting suitable extraction and air supply systems

-

Support with integration alongside fibre laser cutting machines

-

Solutions matched to real-world production environments

Fibre Laser Installations

Recent Fibre Laser Installations

Jan 2nd

2 months ago

Vector FL250 Fibre Laser Cutter Installation – West Yorkshire

Dec 10th, 2025

3 months ago

New Vector FL250 Fibre Laser Installation – Wokingham (3kW Configuration)

Nov 12th, 2025

4 months ago

SF3015 3kW Fibre Laser Installation – Wednesbury, West Midlands

Not sure which Fibre Laser model is right for you? Our team can help.