How to Check & Maintain Vacuum Pump Filters for CNC Routers

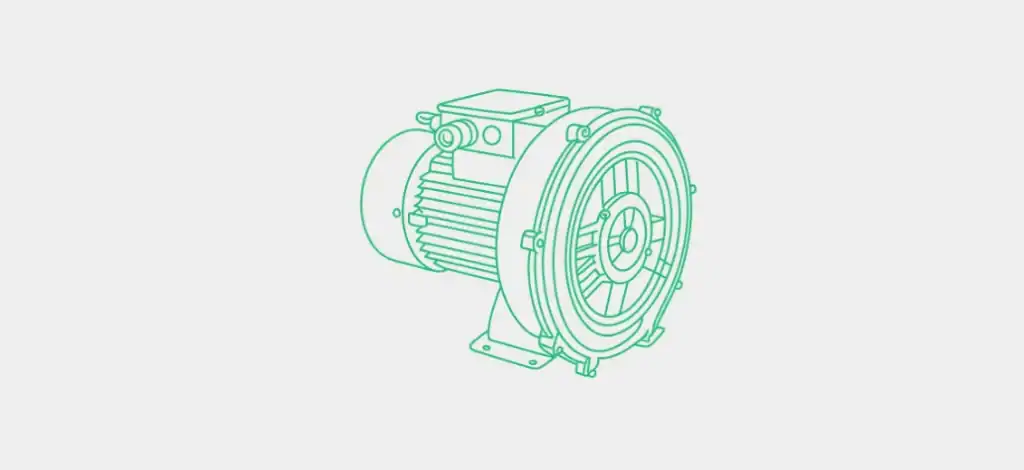

Step 1: Access the Filter

Remove the cap, setting it aside safely—remember, it often houses rubber seals, so keep these protected.

Extract the filter gently, avoiding contact with delicate surfaces.

Step 2: Inspect and Clean

Look for visible damage such as rips, tears, or excessive wear. If the filter appears compromised, replace it promptly to maintain suction integrity.

Cleaning Methods

Using Compressed Air (Recommended):

Blow from the centre outwards to dislodge debris effectively.

Without Compressed Air:

Place the filter in a bin and gently tap the sides to shake loose dust and debris.

Step 3: Reassemble the Filter Unit

Refit the filter cap—ensure it’s snug and seals are correctly seated.

Reclip the hood, locking it securely back in place.

Why This Matters

- A clean filter ensures optimal vacuum performance, reducing material movement during cuts and improving accuracy.

- Regular maintenance extends filter life and protects the vacuum pump from damage caused by dust ingress.

Mantech Advantage

Visit our CNC Router Range or head straight to Book a Demo Today—we’re here to help.

Contact Details

UK Sales & Support: 0121 541 1444

Ireland: +353 83 804 8820