Vacuum Bed Best Practices for CNC Routers: A Beginner’s Guide

Are you new to CNC router setups and aiming to optimise your vacuum bed performance? Understanding the essentials of vacuum bed best practices can dramatically increase work-holding grip, accuracy, and efficiency. In this guide, we’ll walk you through the core principles—from material considerations and gasket installation to surface preparation—helping you master reliable vacuum holding and making a strong case for partnering with Mantech Machinery for your next CNC investment.

Understanding the Concept of a Vacuum Bed

A vacuum bed works by sucking your workpiece down against a sacrificial board, using lateral friction to hold it securely. The key insight? More surface contact area equals stronger grip.

- Large surface area: The greater the contact, the better the lateral holding force.

- Material type matters:

- Porous materials (e.g., certain woods, foam): They allow air to pass through but often have rough surfaces that enhance friction—helping compensate for weaker sealing.

- Non‑porous materials (e.g., acrylic): Provide strong sealing and pull-down force, thanks to minimal air leakage.

This understanding helps you choose the right combination of materials for optimal vacuum performance.

Neoprene Zone Gasket Sealing

Correct gasket installation is vital to a sealed, efficient vacuum system.

- Always use one continuous length of neoprene gasket per zone—minimising joins reduces potential leak points and preserves vacuum pressure.

- Avoid stretching the gasket to fit: stretching narrows the gasket, creating an uneven seal that compromises holding strength.

- Ensure grooves are clean and debris-free before seating the gasket.

- Carefully butt the gasket ends together to form a perfect seal.

- Once installed, place the sacrificial board over the gasket, apply vacuum, and check all pipework and joints for leaks to ensure consistent pull-down across the zone.

With proper sealing, air only flows through the area directly under the component via the board’s fibres—maximising lateral friction.

Sacrificial Surface Skimming

Achieving a flat, porous sacrificial surface is key for both grip and machining accuracy.

- Skimming removes the factory surface “skin” on both sides of the sacrificial MDF board—helping air penetrate the surface fibres more effectively and ensuring the surface is level.

- A level board supports consistent machining depth and improved part accuracy.

- Although you can skim manually, specialised skimming tools (available for around £50-100) can save significant time—especially for large bed surfaces.

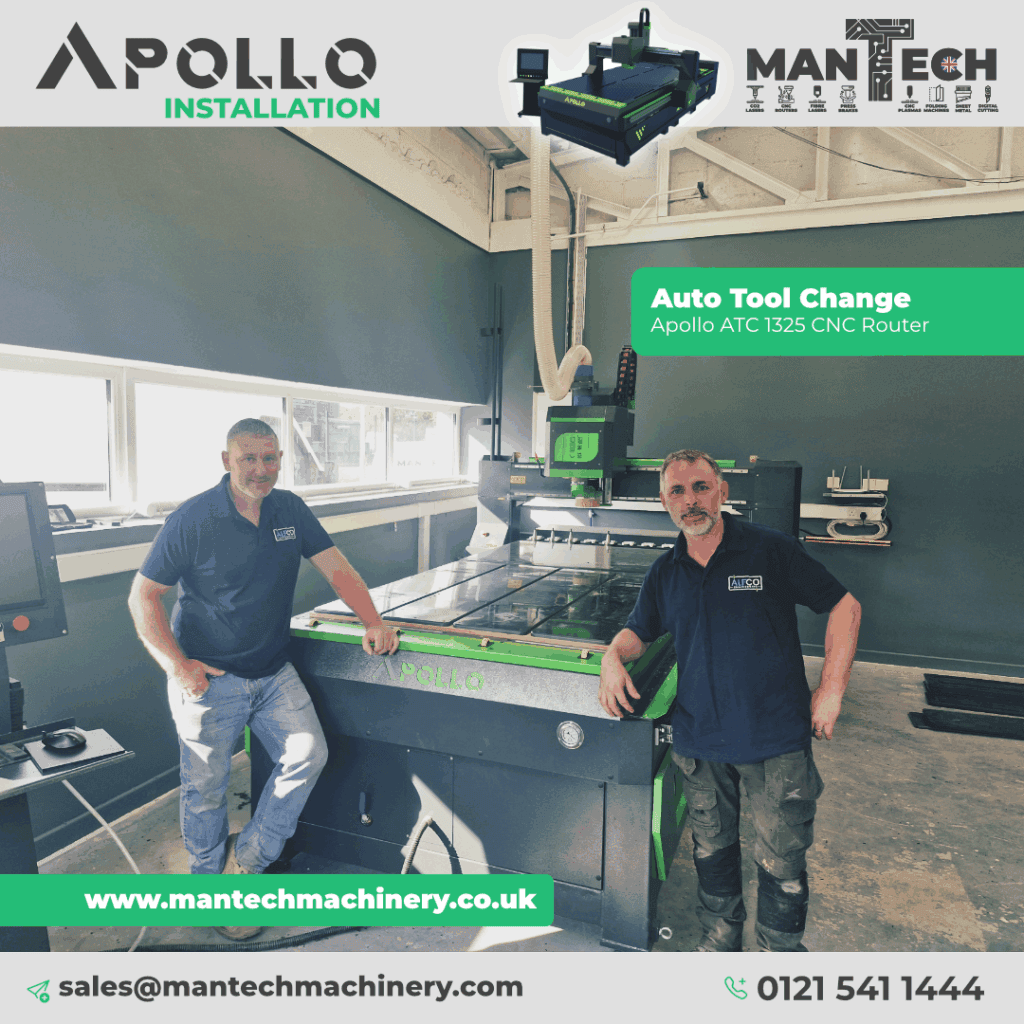

The Mantech Advantage

At Mantech Machinery, we understand that precision and consistency matter—especially when you’re new to CNC vacuum bed setups.

- Over 25 years in business: Our experience helps professionals set up vacuum bed systems confidently.

- Tailored advice and support: We can guide you on choosing the right gasket, materials, sacrificial board, and even recommend tools like skimmers to work efficiently.

- Complete CNC router solutions: Pair your vacuum bed knowledge with our high-quality routers for a system that delivers accuracy, surface finish, and peace of mind.

By mastering vacuum bed concepts—from material considerations and gasket placement to skimming techniques—you’ll ensure that your CNC router maintains reliable work holding and precision.

Ready to explore vacuum bed‑enabled CNC routers or get expert advice?

Visit our Machinery Range or Contact us:

UK: 0121 541 1444

Ireland: +353 83 804 8820

Let Mantech’s experience support your precision and productivity goals.

CNC Machines

CNC Routers