CNC Router vs Fibre Laser: Which Suits Your Application?

When it comes to precision cutting and shaping of materials, CNC routers and fibre lasers are two of the most powerful and versatile tools available. But they serve very different purposes. In this article, we explore what sets them apart, which industries rely on them, and what materials they can handle—so you can decide which technology best suits your application.

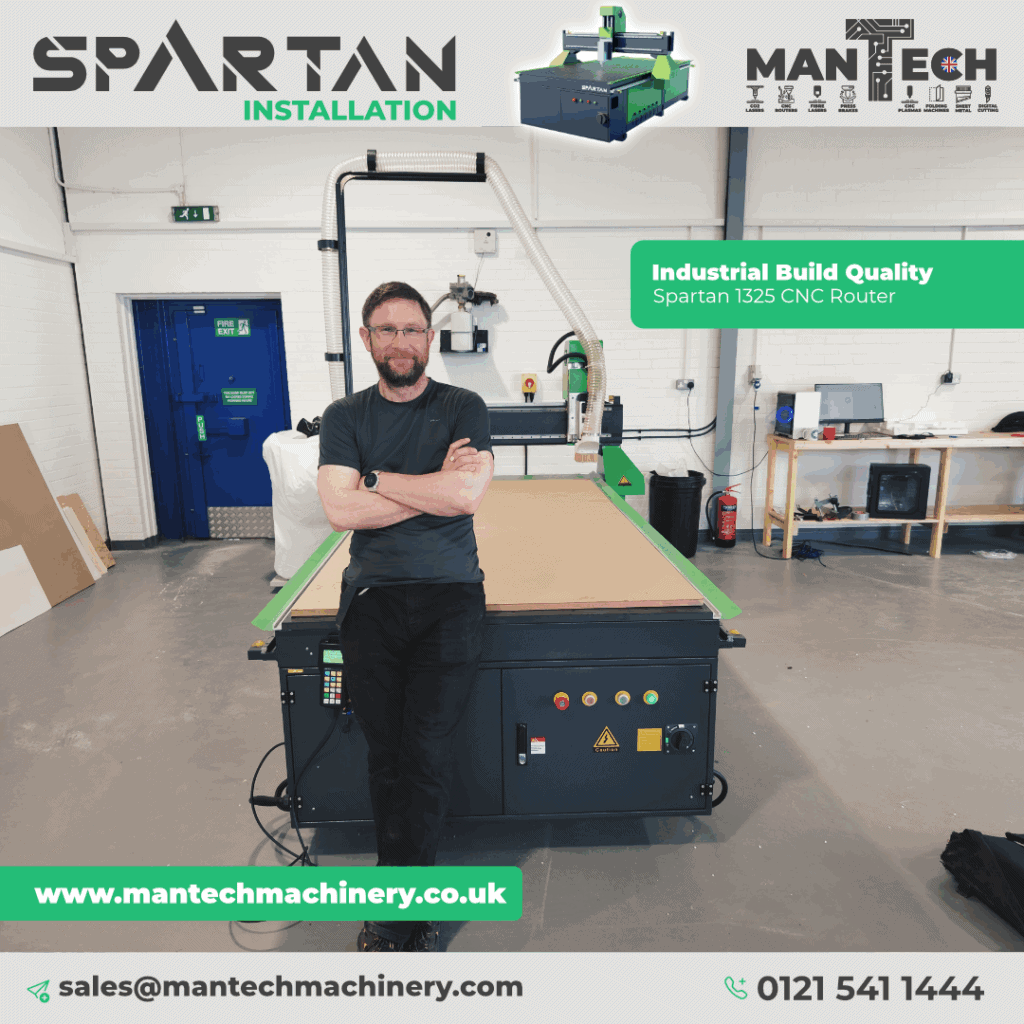

What Is a CNC Router?

CNC (Computer Numerical Control) routers use a high-speed rotating tool to cut and shape a wide variety of materials. These machines operate by physically removing material using a sharp bit or cutter.

Key characteristics of CNC routers:

- Ideal for both 2D and 3D cutting and engraving

- Great for wood, plastics, composites, and some soft metals

- Available in a range of sizes—from desktop to full-sheet industrial models

- Often more affordable and easier to maintain than laser cutters

- Excellent for creating complex curves and contours

CNC routers are a go-to solution for makers, designers, and fabricators working across creative and practical applications.

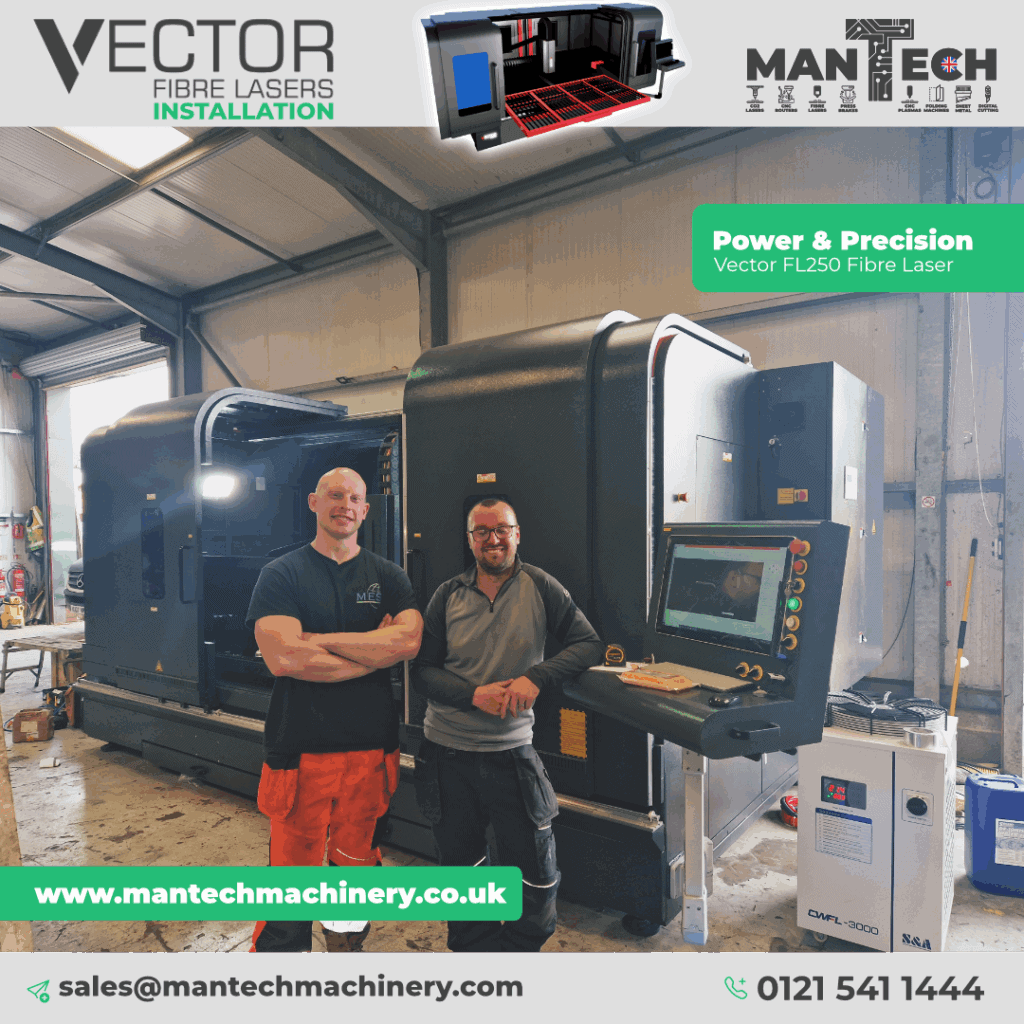

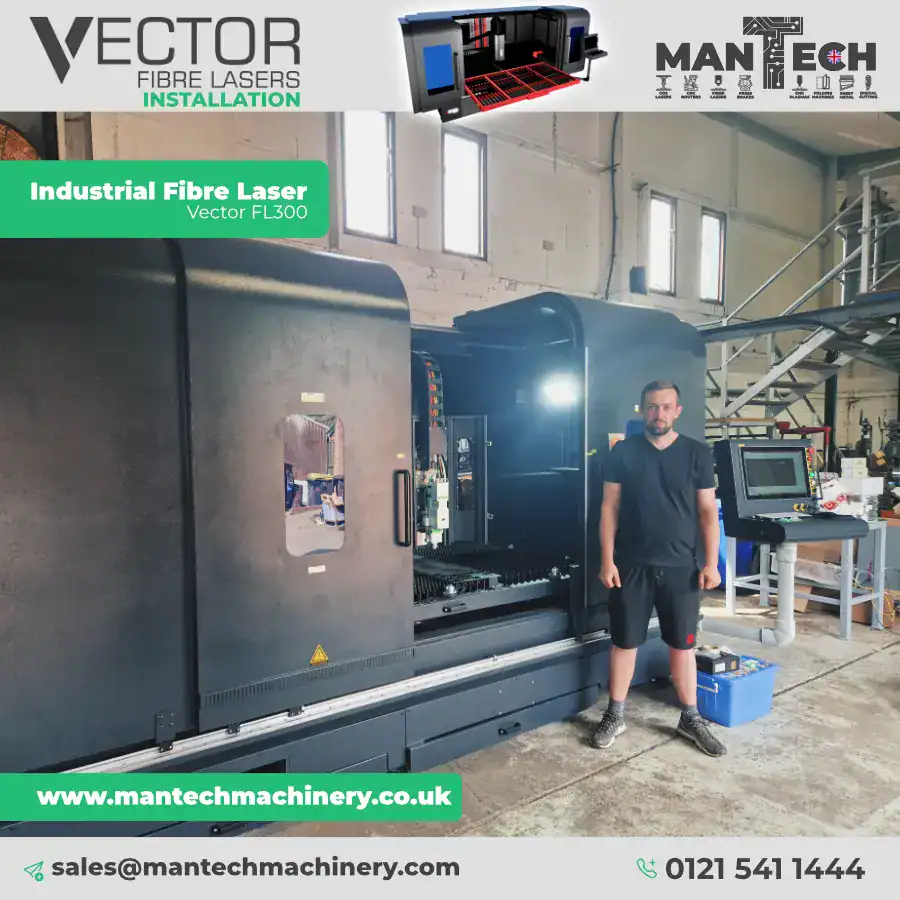

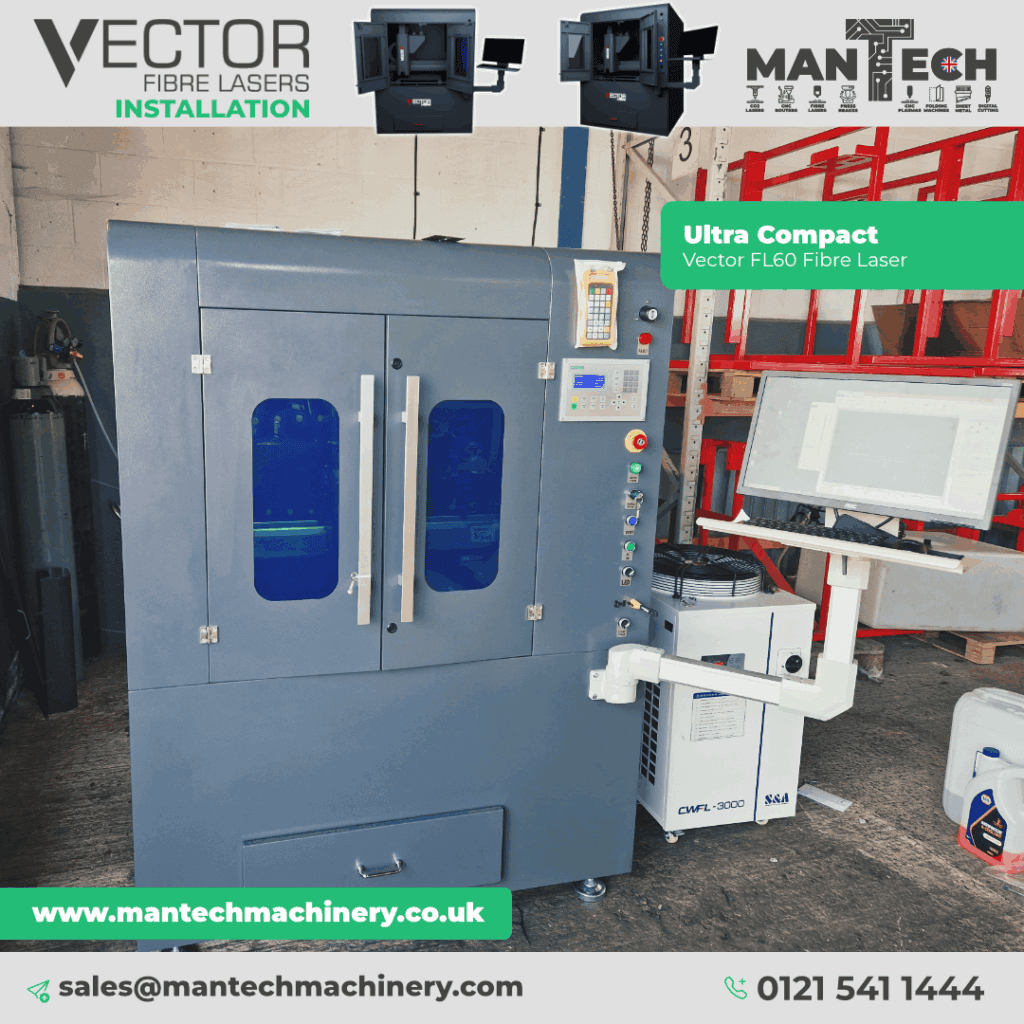

What Is a Fibre Laser?

Fibre lasers use concentrated light energy to cut through metals with incredible precision. The beam is delivered via fibre optics, allowing for high-speed, high-accuracy cutting with minimal waste.

Key features of fibre lasers:

- Specialised for cutting metals, including stainless steel, aluminium, and copper

- Produce clean, burr-free edges with minimal finishing required

- Offer faster processing speeds and higher precision in thin to medium-thickness materials

- Enclosed and often safer for operators

- Typically have a higher initial investment but lower ongoing consumable costs

Fibre lasers are favoured in industries where accuracy, repeatability, and speed are paramount.

Industries That Use Fibre Lasers

Fibre lasers are widely used in high-precision, high-performance sectors such as:

- Automotive industry – for chassis components, brackets, and exhaust systems

- Aerospace industry – cutting lightweight, high-strength materials

- Signage and display – producing sharp-edged metallic signs and letters

- Electronics industry – micro-fabrication of intricate metal components and housings

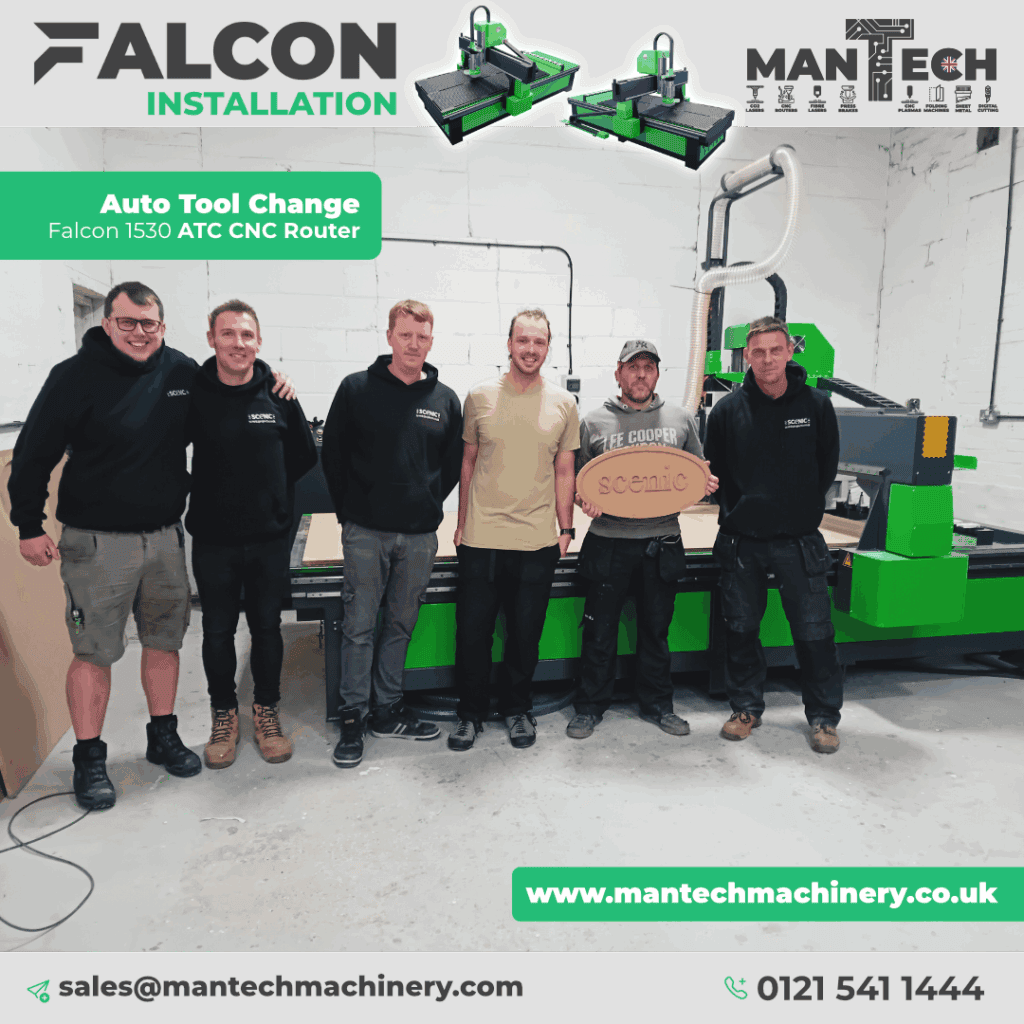

Industries That Use CNC Routers

CNC routers are found in workshops and production lines where creativity meets utility:

- Custom joinery and furniture making

- Camper van and vehicle conversions

- Personalised giftware and engraved items

- Product design and prototyping

- Education and vocational training

- Sign making using plastic and composite boards

- Theatre and film set design

- Architectural modelling, POS displays, and more

What Materials Can Each Machine Cut?

CNC Router Materials

CNC routers are highly versatile, especially in entry-level formats. Here’s a (non exhaustive) breakdown of what they can cut:

| Woods | Plastics | Composites & Others |

|---|---|---|

| Oak | Acrylic | ACM (Alcubond, Dibond) |

| Birch | Polycarbonate | Foamex |

| MFC | ABS | Composite Fibreboard |

| Plywood | PVC | Solid Surface (Corian etc) |

| Walnut | HPDE | Carbon Fibre |

| Pine | Peek | Graphite |

| Redwood | Delrin | Tool Box Foam |

| Leather | Plexiglass | Laminated Woods |

| OSB Board | Tufnol | Vermiculite Board |

| Cedar | Peek | Trespa |

| Cherry | HPL | Aluminium |

| Elm | Brass |

Fibre Laser Materials

Fibre lasers are optimised for metal cutting. Typical compatible materials include:

- Stainless Steel

- Mild and Carbon Steel

- Aluminium

- Copper

- Brass

- Titanium

These machines are ideal for metalworking applications requiring speed, repeatability, and low tolerance for error.

Key Differences at a Glance

| Feature | CNC Router | Fibre Laser |

|---|---|---|

| Cutting Method | Rotating tool (physical contact) | Focused laser beam (non contact) |

| Best for… | Wood, plastics, composites | Metals (especially sheet metals) |

| Material Versatility | High | Medium (mostly metals) |

| Typical Industries | Joinery, design, signage | Automative, aerospace, electronics |

| Maintenance Needs | Tool replacement, dust extraction | Minimal wear parts, enclosed safety |

| Cost of Entry | Lower | Higher initial investment |

| Speed & Precision | Moderate to high | Very high (especially with thin metals) |

Maintenance:

CNC Router Maintenance

To keep your CNC router running efficiently and safely, regular upkeep is essential. Explore CNC router servicing tips and demos in our helpful maintenance guides:

Fibre Laser Maintenance

Fibre lasers require less mechanical upkeep but still need regular attention for long-term performance.

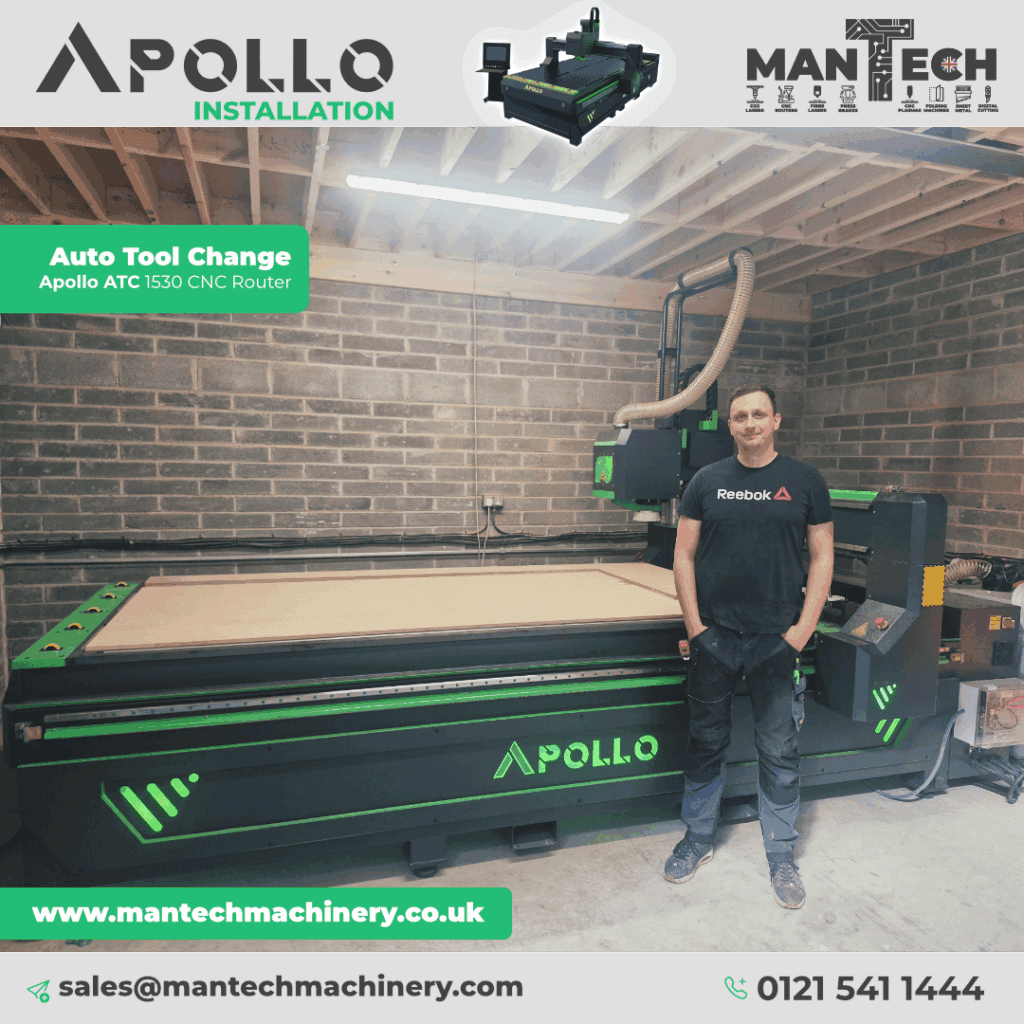

Which Machine Is Right for You?

The decision between a CNC router and a fibre laser comes down to your:

- Primary materials – Wood and composites? Go CNC. Metals? Fibre laser is your tool.

- Level of detail – Fibre lasers excel in micro-precision. CNC routers offer versatility for contouring and shaping.

- Production needs – If speed, cleanliness, and automation are essential, fibre lasers may provide greater efficiency.

- Budget and workshop space – CNC routers are often more affordable and beginner-friendly, especially in compact formats.

Need Help Deciding?

At Mantech UK, we support professionals across industries with expert advice and hands-on demonstrations. Whether you’re just getting started or looking to scale your operations, we’ll help you choose the right machine for your application.

📞 Contact us today or book a demo to explore your options in person.

📞 UK: 0121 541 1444

🌐 Discover: CNC Router Solutions | Fibre Laser Solutions

CNC Routers

Fibre Laser