CNC Machines – What are they?

Introduction

What is CNC Machining?

The History of CNC Machines

The origins of CNC Machines:

The origins of CNC machines can be traced back to the 1940s when the first numerical control (NC) machines were developed. These early machines were controlled by punched tape, which contained instructions that were read by the machine and used to guide its movements. While NC machines were a major improvement over manual machines, they were limited by the need to create specialized tapes for each different operation.

In the 1950s, researchers began to explore the use of computers to control manufacturing equipment. The first CNC machine was developed in 1952 by the Massachusetts Institute of Technology (MIT) and the US Air Force. This machine used a computer to control the movement of a cutting tool, enabling greater precision and efficiency.

Over the following decades, the technology behind CNC machines continued to evolve, with improvements in computer processing power and software design enabling increasingly complex and sophisticated manufacturing operations. Today, CNC machines are used in a wide range of industries, from automotive and aerospace manufacturing to electronics and medical device production.

In summary, the origins of CNC machines can be traced back to the 1940s and the development of numerical control machines. The use of computers to control manufacturing equipment was first explored in the 1950s, leading to the development of the first CNC machine. The technology behind CNC machines has continued to evolve over the decades, enabling increasingly precise and sophisticated manufacturing operations.

The rise of CNC Machines in the manufacturing industry:

Another advantage of CNC machines is their versatility. They can be programmed to perform a wide range of manufacturing operations, including cutting, drilling, milling, and grinding. This makes them ideal for use in a variety of industries, including automotive, aerospace, electronics, and medical device manufacturing.

In addition to their precision and versatility, CNC machines also offer greater flexibility in the design and production process. CAD (Computer-Aided Design) software allows designers to create 3D models of parts and components, which can be used to program CNC machines to produce the desired shape and size. This means that manufacturers can quickly and easily make changes to the design or production process as needed.

Overall, the rise of CNC machines has had a profound impact on the manufacturing industry. It has allowed for greater efficiency, precision, and flexibility in the production process, while also reducing labour costs and increasing productivity. As technology continues to evolve, it is likely that we will see even more advanced and sophisticated CNC machines in the future.

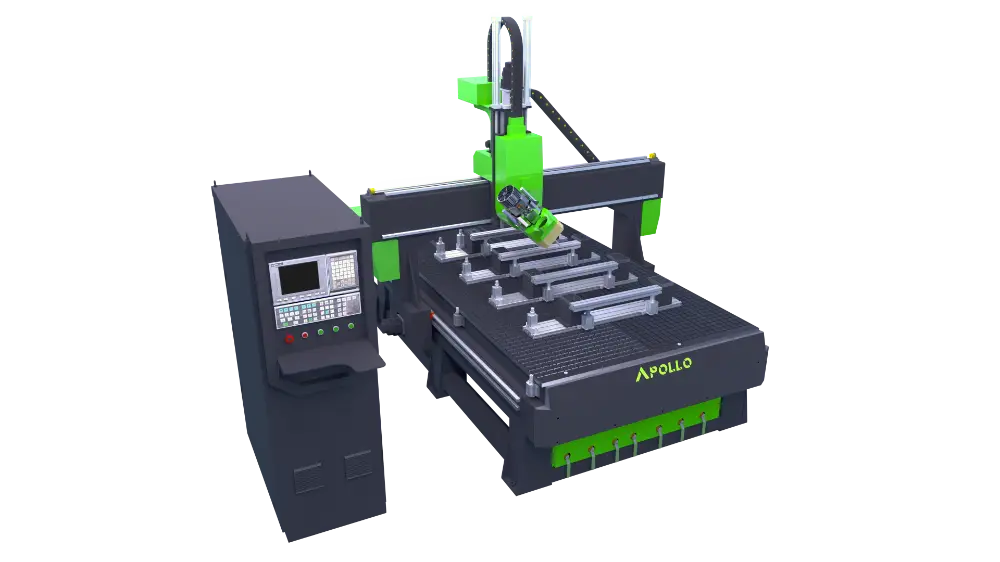

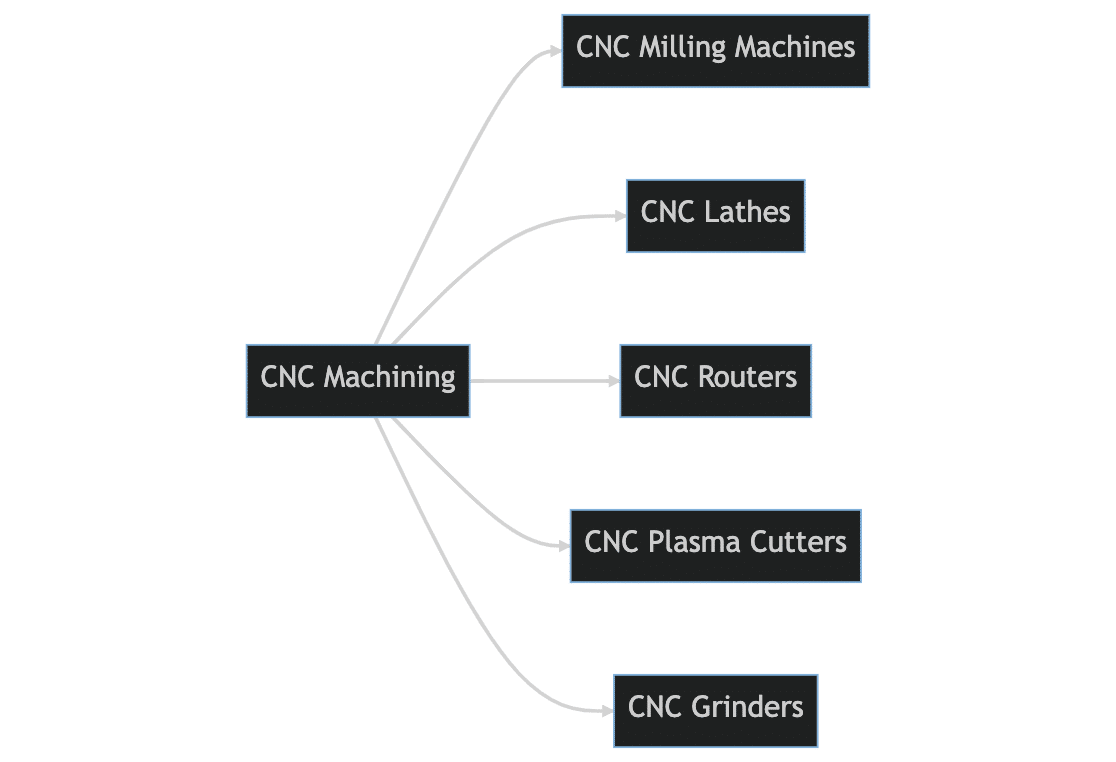

Types of CNC Machines

- CNC Routers – are used for cutting, drilling, and shaping materials such as wood, plastic, and metal.

- CNC Lathes – used for shaping workpieces by rotating them against a cutting tool.

- CNC Milling Machines – used to remove material from a workpiece by rotating a cutting tool.

- CNC Plasma Cutters – used for cutting materials using a high-velocity stream of plasma.

- CNC Grinders – used for precision grinding operations such as surface grinding, cylindrical grinding, and others.

- CNC EDM Machines

- CNC Press Brakes – used for bending and shaping sheet metal components using a variety of tooling to create both simple and complex shapes.

Applications of CNC Machines

- Aerospace industry

- Automotive industry

- Construction industry

- Electronics industry

- Medical industry

- Woodworking industry

- Jewellery industry

- Prototyping industry

Advantages of CNC Machines

- Improved accuracy and precision of parts and components

- Higher efficiency and faster production times

- Lower costs due to reduced labour requirements

- Consistent and repeatable results

- Flexibility in design and production

How to Choose The Right CNC Machine

- Evaluate the capabilities of each machine

- Choose the right size and capacity for your needs

- Understand the maintenance and operating costs

- After-sales

Conclusion

With the right knowledge and equipment, manufacturers can take advantage of the benefits offered by CNC machines to optimize their production processes and stay ahead of the competition.

Frequently Asked Questions

What does CNC stand for?

CNC stands for Computer Numerical Control.

What types of materials can CNC machines work with?

CNC machines can work with a range of materials, including metals, plastics, wood, and composites.

Are CNC machines expensive?

The cost of CNC machines varies depending on the type, size, and capabilities of the machine. Our CNC Routers, CNC Plasma Cutters and CNC Press Brakes are all within competitive price points.

Can anyone operate a CNC machine?

Operating a CNC machine requires the right skills. However, with the right training and experience, anyone can learn to operate a CNC machine.

How do CNC machines improve efficiency in manufacturing?

CNC machines improve efficiency in manufacturing by reducing labour costs, increasing production rates, and ensuring consistent quality of products.