Quick Fibre Laser Welder Quote

Customer Quotation Form

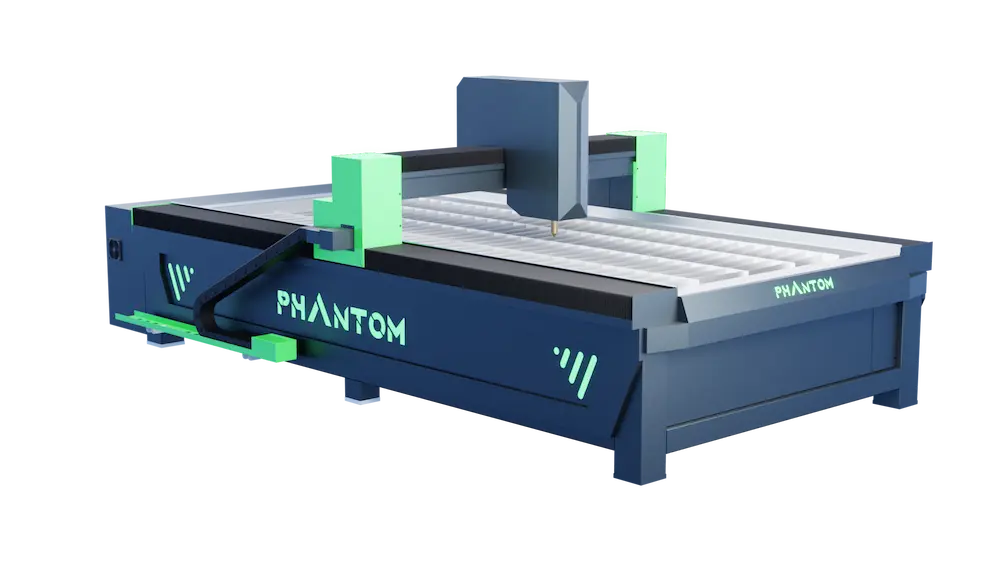

| Phantom CNC Plasma Cutters Features | Description |

|---|---|

| Heavy-Duty Framework | Allows for thicker materials to be supported on the cutting bed. |

| Complete Control | Comes with M-TECH Control podium and software, offering user complete control. |

| Wide Range of Cutting Torches | Range of cutting torches available for almost any CNC Plasma cutting application. |

| Hypertherm Power Sources and Consumables | Offers a range of options, such as Hypertherm power sources and consumables. |

| Upgrades Available | Numerous upgrades which can be opted for upon ordering. |

| Warranty | Machines come with a warranty ranging from 1-5 years, extended warranties and on-site maintenance programs available. |

| Cutting Technique | Uses a plasma stream to transfer energy to conductive work material, enabling fast and accurate cutting through very thick metals. |

| Industries/Sectors using Phantom CNC Plasma Cutters | Shipbuilding, Mining, Mechanical fabrication, Steel fabricators, Construction, Automotive, Sign making, General construction, Aerospace |

| Phantom CNC Plasma Cutters Summary | Powerful and efficient plasma cutters with heavy-duty framework, complete control podium and software, wide range of cutting torches, and Hypertherm power sources and consumables. Perfect for a wide range of industries and applications. |

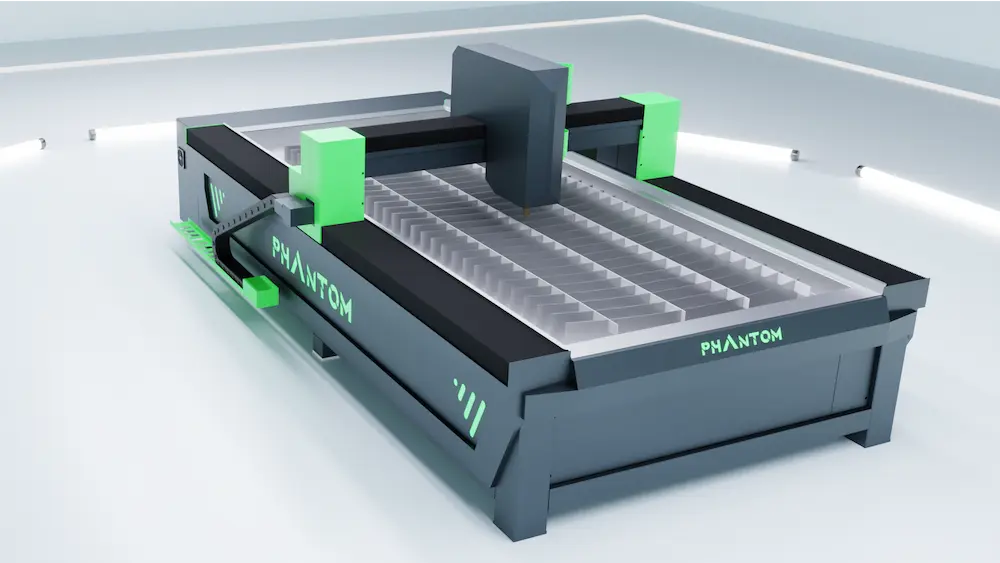

| Mechanical Design | |

|---|---|

| Bed Sizes (mm) | Available in 1400 x 1400, 1400 x 2600, 1600 x 3100, 2000 x 3000, 2000 x 4000 |

| Square Linear Guide Rail with Rack & Pinion | Delivers precision and stability for XY axis movements. |

| Cylindrical Linear Guide Rail with Reciprocating Ball Screw | Specially designed for Z-axis accuracy. |

| Dual Drive Y-Axis | Enhanced control and performance operation. |

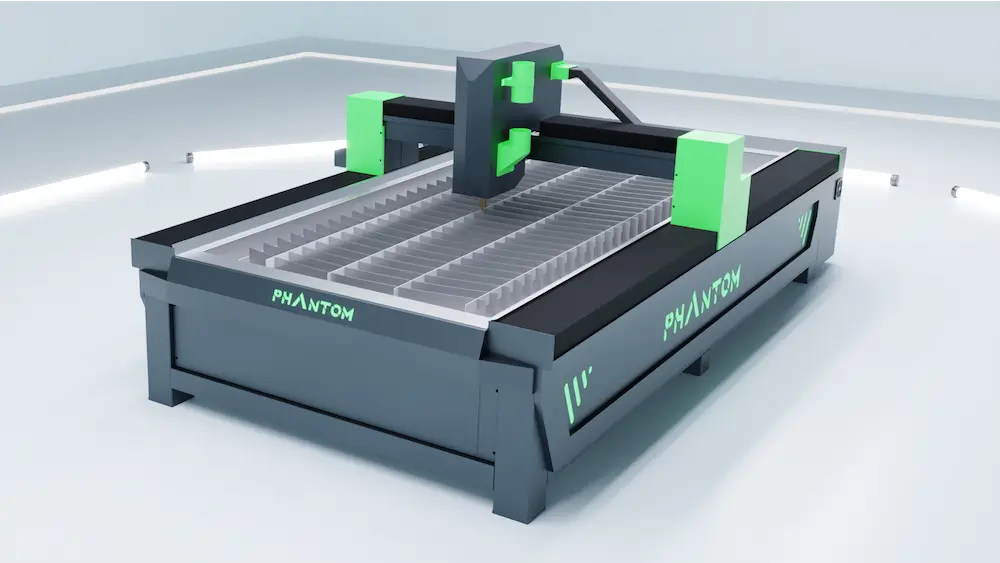

| Control System | |

|---|---|

| 3-Axis Control System | Utilises Closed Loop Hybrid Driver technology for XYZ axes. |

| MTECH CNC Motion Control System | Delivers precision and stability for XY axis movements. |

| THC (Torch Height Control): | Incorporates Microstep Digital Torch Height Control and High-Speed Precision Arc Voltage Control. |

| Dual Drive Y-Axis | Enhanced control and performance operation. |

| Software and Additional | |

|---|---|

| Cad-Cam Vectric Cut 2D Software: | Includes a CAD design package and can import various file formats like DWG, DXF, PDF, etc. |

| Component Nesting | Material optimisation through intelligent nesting features. |

| Delivery to Site | Included with the purchase. |

| Power Max Package | Consists of a 50 ft torch lead and remote on/off switching. |

| Machine Interface Cable | Comes with a voltage divider signal. |

| Air Filtration Kit | Includes a 1-micron filter and auto-drain moisture separator. |

| 12-Month Parts & Labour Guarantee | For peace of mind and assured quality. |

| Customer Support | 24/7 technical support is available. |

| Power Source | Max Pierce Thickness | Max Thickness – Edge Start |

|---|---|---|

| Single phase, 220-240v, 45A | 12 mm | * |

| 3 phase, 415v, 65A | 18 mm | 25 mm |

| 3 phase, 415v, 85A | 20 mm | 30 mm |

| 3 phase, 415v, 105A | 22 mm | 35 mm |

| 3 phase, 415v, 125A | 25 mm | 40 mm |