Unlocking Precision and Power: The Definitive Guide to Fiber Laser Technology

This comprehensive guide dives deep into the world of fiber laser technology. We’ll explore the science behind their exceptional performance, uncover their diverse advantages over traditional laser systems, and illuminate the vast range of industries they are transforming. Whether you’re an engineer, a business owner, or simply curious about the future of manufacturing, this article will equip you with the knowledge to understand and appreciate the power of fiber lasers.

What are Fiber Lasers and How Do They Work?

Decoding the Science: How Fiber Lasers Achieve Superior Performance

- The Seed Laser: The journey begins with a seed laser, a low-power laser that generates the initial beam.

- Fiber Optic Amplification: This seed beam is then channeled into the specially doped optical fiber. As the light travels through the fiber, it interacts with the rare-earth elements, which are energized by pump diodes (typically high-power LEDs or laser diodes).

- Stimulated Emission: The energized rare-earth elements release photons, amplifying the laser beam’s intensity. This process of stimulated emission occurs repeatedly along the length of the fiber.

- High-Quality Output Beam: The amplified beam emerges from the fiber with exceptional characteristics:

- Excellent Beam Quality (TEM00): Fiber lasers typically produce a near-diffraction-limited beam (TEM00 mode), resulting in a very small focal spot and high power density. This is crucial for precision applications.

- High Efficiency: The fiber design and direct diode pumping contribute to significantly higher electrical-to-optical efficiency compared to other laser types, reducing operating costs.

- Robust and Reliable: The fiber laser design is inherently robust, less susceptible to misalignment, and requires minimal maintenance due to the absence of free-space optics and cooling requirements in the laser gain medium.

The Unmatched Advantages of Fiber Laser Technology

Why Choose Fiber Lasers? A Clear Edge Over Traditional Systems

- Superior Beam Quality and Precision: As mentioned, the TEM00 beam quality allows for extremely fine focusing. This translates to:

- Enhanced Cutting and Engraving Resolution: Achieve intricate designs and cleaner cuts with minimal material waste. Discover Fibre Laser Cutters.

- Improved Welding Quality: Create narrow, deep welds with minimal heat-affected zones, crucial for sensitive materials and precise joining. Discover Fibre Laser Welders.

- High-Resolution Marking and Micro-Machining: Ideal for applications demanding minute detail and accuracy. Discover Fibre Laser Engraving and Marking Machines.

- Increased Efficiency and Reduced Operating Costs:

- Lower Power Consumption: Fiber lasers are significantly more energy-efficient, translating to lower electricity bills and a reduced carbon footprint.

- Minimal Maintenance: The robust design and long diode lifetimes drastically reduce maintenance downtime and costs associated with consumables and repairs.

- Faster Processing Speeds: In many applications, fiber lasers can achieve faster cutting, welding, or marking speeds compared to CO2 or YAG lasers, boosting productivity.

- Compact and Flexible Design:

- Smaller Footprint: Fiber laser systems are often more compact and lighter, saving valuable floor space and enabling easier integration into existing production lines.

- Fiber Beam Delivery: The laser beam is delivered through a flexible fiber optic cable, allowing for easier integration into robotic systems and remote workstations, and simplifying complex beam paths.

- High Reliability and Uptime:

- Long Diode Lifetimes: Modern fiber laser diodes boast exceptionally long lifespans (often exceeding 50,000 – 100,000 hours), ensuring consistent performance and minimising downtime.

- Robustness in Industrial Environments: Fiber lasers are less susceptible to environmental factors like vibrations and temperature fluctuations, making them ideal for demanding industrial settings.

Applications Across Industries: Where Fiber Lasers Excel

Transforming Industries: The Versatile Applications of Fiber Lasers

Manufacturing & Metal Processing:

Laser Cladding & Additive Manufacturing (Metal 3D Printing): Used for creating wear-resistant coatings and building complex 3D metal parts layer by layer. Key for aerospace, tooling, and customized component production.

Laser Cutting: From intricate sheet metal components to thick plates, fiber lasers offer superior speed and precision for cutting steel, aluminum, stainless steel, brass, copper, and more. Key applications include automotive, aerospace, shipbuilding, and general fabrication.

Laser Welding: Ideal for joining dissimilar metals, thin materials, and applications demanding high weld quality and minimal distortion. Used in battery manufacturing, medical device assembly, and precision engineering.

Laser Marking & Engraving: Creating permanent markings, barcodes, serial numbers, and decorative engravings on a wide range of materials (metals, plastics, ceramics). Used for traceability, branding, and product personalization in industries like electronics, medical devices, and consumer goods.

Laser Cleaning: Precisely removing rust, paint, coatings, and contaminants from surfaces without damaging the base material. Applications include surface preparation for welding, mold cleaning, and heritage restoration.

Medical & Life Sciences:

Medical Device Manufacturing: Precision cutting and welding of components for pacemakers, stents, catheters, and other medical devices.

Biophotonics & Microscopy: Used in advanced imaging and research applications.

Electronics & Semiconductor Industry:

Wafer Dicing: Separating individual chips from silicon wafers with high speed and accuracy.

Laser Wire Stripping: Precisely removing insulation from wires without damaging the conductor.

Renewable Energy:

Battery Manufacturing (as mentioned above): Welding battery components for electric vehicles and energy storage systems.

Aerospace & Defense:

Aircraft engine repair: Laser cladding and welding for repairing and refurbishing critical engine components.

Considering Fiber Lasers for Your Application? Key Factors to Evaluate

Making the Right Choice: What to Consider When Investing in Fiber Laser Technology

Power Level: Determine the appropriate laser power based on material thickness, processing speed requirements, and desired throughput. Higher power lasers are generally needed for thicker materials and faster processing.

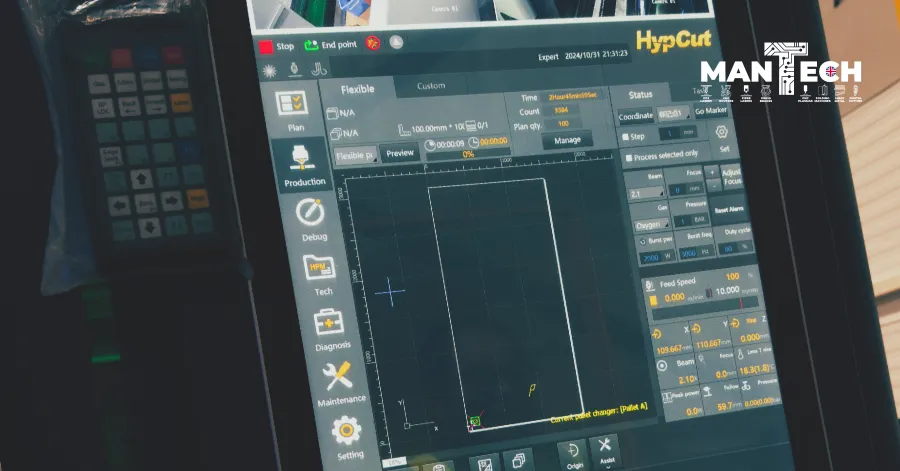

Beam Delivery System: Consider the best beam delivery option for your application – fiber optic cable for flexibility, or direct beam delivery for certain high-power applications.

System Integration: Evaluate how easily the fiber laser system can be integrated into your existing production line or robotic setup.

Supplier Expertise and Support: Choose a reputable supplier with proven experience in fiber laser technology and a strong track record of customer support, training, and service.

Budget and ROI: Assess the initial investment cost and calculate the potential return on investment based on increased efficiency, reduced operating costs, and improved product quality.

The Future is Fiber: Ongoing Innovation and Emerging Trends

Looking Ahead: The Evolution of Fiber Laser Technology

Higher Power and Efficiency: Continued advancements in diode technology and fiber design are leading to even more powerful and energy-efficient fiber laser systems.

Shorter Wavelength Fiber Lasers: Development of fiber lasers emitting in the visible and UV spectrum is opening up new applications in micro-processing, bio-imaging, and advanced materials processing.

Advanced Beam Shaping and Control: Sophisticated beam shaping optics and control systems are enabling even greater precision and flexibility in laser processing, allowing for tailored beam profiles for specific applications.

Integration with AI and Automation: Combining fiber laser technology with artificial intelligence and automation is driving the development of smart, self-optimising laser processing systems for Industry 4.0 applications.

Embrace the Fiber Laser Revolution

Are you ready to explore how fiber lasers can transform your operations? Contact our team of laser experts today to discuss your specific needs and discover the ideal fiber laser solution for your application. Discover Our Full Range of Fibre Lasers