The Business Case for a CNC Router in the UK

Below is a practical, numbers-first guide to deciding whether a CNC router makes commercial sense for your business – followed by a brief overview of Mantech UK’s CNC router range and the types of operations each model unlocks.

What a CNC Router Actually Changes in Your Workflow

Throughput and lead time

Consistency and scrap reduction

Labour reallocation

New capabilities and revenue

Where the Business Case Comes From (9 Levers)

- Cycle-time reduction (minutes per part).

- Setup consolidation (fewer fixtures, automated tool changes).

- Sheet yield improvements (true-shape nesting).

- Secondary operations folded in (drilling, countersinks, engraving).

- Reduced reliance on scarce manual skills.

- Fewer reworks/returns (repeatable accuracy).

- Better planning (predictable, measurable runtimes).

- Safer workflow (clean extraction, enclosed operations).

- New product features (joinery patterns, branding, customisation).

Cost Model—What You’ll Actually Pay For

One-off / upfront

- Machine purchase price (varies widely by size, spindle power, drive system, and options such as ATC).

- Tooling and collets (starter set for your core materials).

- Workholding (vacuum bed, pumps, pods, clamps, spoilboards).

- Dust extraction integration (and filtration where required).

- Electrical provision (single- vs three-phase; correct breakers and cabling).

- CAD/CAM software (often included with Mantech routers—see range notes below).

Operating

- Energy (spindle, vacuum pump, extraction).

- Tooling wear/replacement.

- Preventive maintenance (lubrication, belts, filters).

- Operator time (setup, loading, QA, simple maintenance).

- Finance/lease payments if applicable.

Industry price context (UK)

- Broad market range: ~£6k to £80k+ depending on size/spec.

- Example Mantech entry and ATC reference points (see range section).

A Simple ROI Framework You Can Reuse

- Gross time saved per part: (Manual minutes − CNC minutes) × parts/month

- Labour cost saved: (Gross time saved ÷ 60) × blended labour rate

- Material savings: (Old scrap rate − New scrap rate) × sheet cost × sheets/month

- New revenue (optional): Incremental SKUs or higher throughput × gross margin/part

- Operating costs added: Energy + tooling wear + maintenance + finance

- Annual ROI: (Labour + material + new margin − added operating costs) ÷ annualised machine cost

Checklist – Is Your Shop a Good Fit Right Now?

- Consistent backlog where cutting/profiling is the bottleneck

- Repeatable parts or panels with standard materials (MDF, ply, laminates, acrylics, composites, aluminium)

- Frequent reworks due to tolerance/finish from manual methods

- Need for accurate hole patterns, joinery, or engraving

- Desire to consolidate subcontracted routing into in-house control

- Willingness to standardise tooling and fixtures

Specification Choices That Matter (and Why)

Table size & gantry clearance

Spindle power & speed range

Drives and rigidity

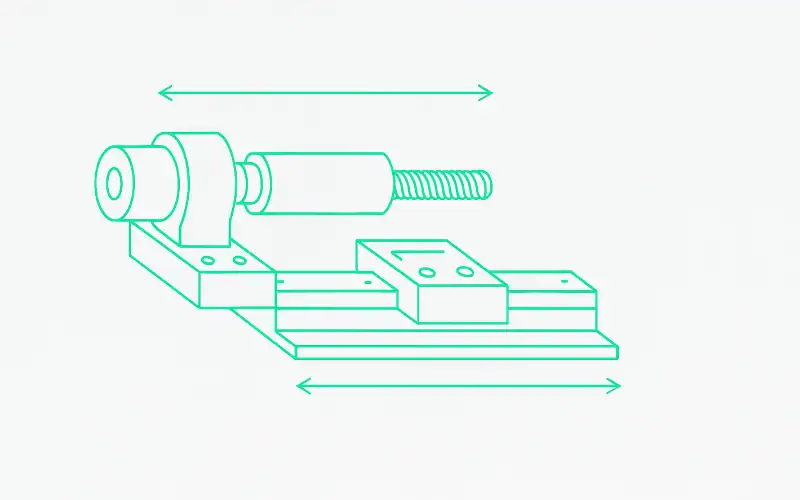

Workholding

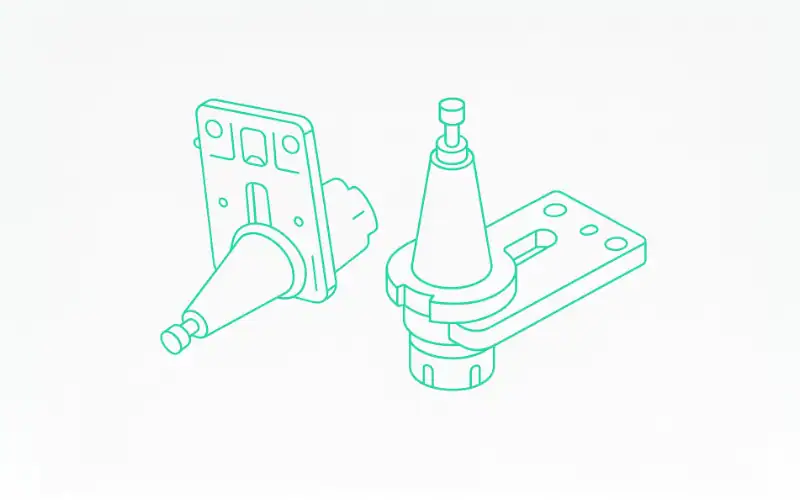

Tool change

Software & control

Implementation Roadmap That Keeps Productivity High

- Process mapping: Identify the parts and SKUs best suited for CNC first.

- Tooling standards: Define a starter tool library (IDs, holders, offsets).

- Workholding plan: Spoilboard, gasket zoning, and datum strategy.

- Program templates: Set naming, post-processor, and safe moves.

- Training & switch-over: Start with a pilot SKU; measure runtime, scrap, and QA.

- Scale-up: Extend to more SKUs, and add QA checkpoints.

- Review: Compare actuals vs ROI model every quarter; tune feeds, strategies, and nesting.

Mantech UK’s CNC Router Range – At a Glance

| Model | Typical Sizes | Key Features | Ideal For | Warranty & Support | Guide Price |

|---|---|---|---|---|---|

| Spartan (entry-industrial) | 600×900 mm to 2000×4000 mm* | Includes Vectric VCarve Pro; delivery, installation & support included | Sign-making, woodwork, plastics, education | 12-month UK warranty | From £8,315 + VAT |

| Falcon ATC (automatic tool change) | 1300×1300 mm to 2000×6000 mm* | 9 kW air-cooled spindle; 10-tool ATC (upgradeable to Knife cutter or drill bank); vacuum table; includes Vectric VCarve Pro | High-mix, multi-tool production workflows | 2-year UK warranty | From £17,360 +VAT |

| Apollo ATC (heavy-duty, UK-designed) | 1300×1300 mm to 2000×6000 mm * | Fast automatic tool change; high-precision, heavy-duty platform for continuous industrial duty | Continuous production with advanced automation needs | 2-year UK warranty | From £27,860 +VAT |

Line-up, breadth of models

How to Match a Mantech Router to Your Use Case

- Prototyping, signage, education, light fabrication: Spartan

- Production joinery, panel processing, plastics/composites with future ATC plans: Apollo M (upgradeable)

- High-mix, multi-tool production, nested-based manufacturing: Falcon ATC

- Heavy-duty, continuous industrial duty with advanced automation: Apollo ATC

Example Payback Scenario (Replace With Your Real Numbers)

- Current: 40 minutes/part manual; 120 parts/month; labour £22/hour.

- With CNC: 10 minutes/part including tool changes and handling.

- Labour saving: (40−10)=30 min × 120 = 3600 min = 60 hours/month ≈ £1,320/month.

- Material saving: 2 fewer sheets wasted/month at £80/sheet = £160/month.

- Operating adds: Energy/tooling/maintenance ≈ £220/month (illustrative—replace with your actuals).

- Net monthly improvement: £1,320 + £160 − £220 = £1,260.

- If finance is £900/month, you’re cash-positive £360/month from month one; capital purchase payback follows the same structure using the annualised cost.

FAQs

What materials can I process?

How hard is the training ramp?

What about support and warranty?

Conclusion—When the Numbers Say “Go”

If cutting, drilling, and profiling are gating your throughput—or if scrap, rework, and schedule slippage are hitting margins—a CNC router is often the most direct, measurable fix. Build your ROI with your actual parts, then match the specification to the work. Mantech UK’s CNC Router range spans entry-industrial through heavy-duty ATC platforms, with delivery, installation, training, and UK-based support—so you can focus on output, not integration.