Unlocking Precision: The Ultimate Guide to Steel Laser Cutting Machines for Your Business

From increased efficiency and reduced waste to unparalleled accuracy, discover how embracing laser cutting technology can unlock new possibilities for your projects. Prepare to revolutionise your approach to fabrication and stay ahead of the competition with cutting-edge insights that will empower your business for success.

How Steel Laser Cutting Works

The precision of laser cutting is enhanced by the use of assist gases, such as oxygen, nitrogen, or compressed air, which are blown through a nozzle coaxially with the laser beam. These gases help to remove molten material from the cut area, thus ensuring a clean and smooth edge.

The type of assist gas used can also affect the cutting speed and quality. For instance, oxygen is often used for cutting thicker steel due to its ability to create an exothermic reaction that adds more heat to the cutting process, whereas nitrogen is used for cutting stainless steel to prevent oxidation and achieve a clean cut.

Another crucial component in the laser cutting process is the CNC system. This system uses a software program to control the movement of the laser cutting head. By following the programmed path, the CNC system ensures that the laser cuts the steel according to the precise dimensions required. This level of control allows for intricate designs and complex shapes to be cut with high accuracy, making laser cutting an invaluable tool in modern manufacturing.

Advantages of Using Laser Cutting for Steel

Efficiency is another major benefit of laser cutting. The high speed of laser cutting machines means that they can process materials much faster than traditional cutting methods. This increased productivity can lead to shorter production times and quicker turnaround for projects. Additionally, laser cutting is a non-contact process, which means there is minimal wear and tear on the cutting tools, leading to reduced maintenance costs and longer machine life.

Laser cutting also offers significant material savings. The narrow kerf (width of the cut) produced by the laser means that there is less waste material. This efficiency not only reduces costs but also makes laser cutting a more environmentally friendly option. Furthermore, the ability to nest multiple parts closely together on a single sheet of steel maximises material usage and minimises scrap.

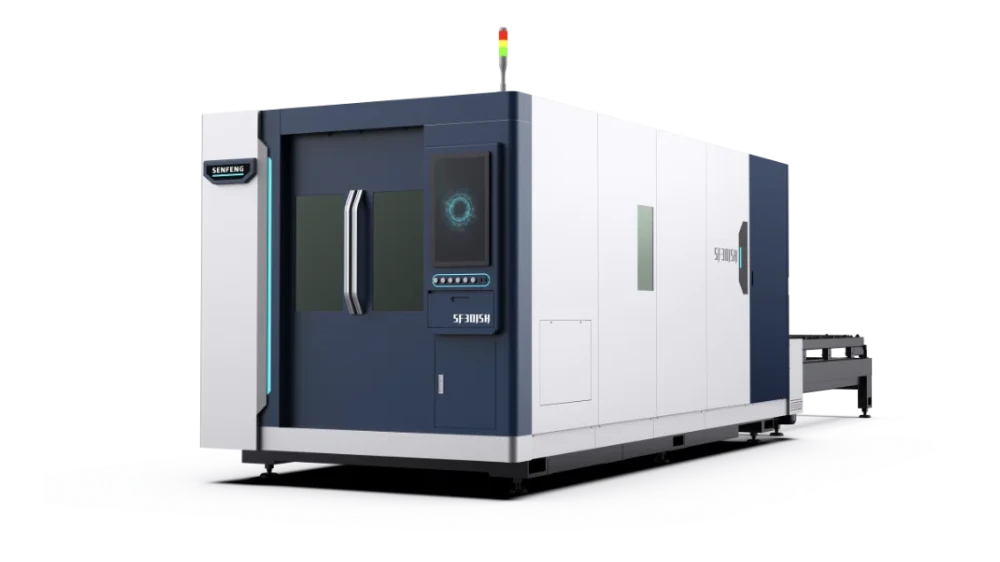

Key Features to Look for in a Laser Cutting Machine

CO2 lasers are one of the oldest and most widely used laser cutting technologies. They operate by electrically stimulating a gas mixture of carbon dioxide, nitrogen, and helium to produce a laser beam. CO2 lasers are highly effective for cutting non-metallic materials such as wood, acrylic, and plastics, in addition to metals like steel and aluminium. They are known for their high-quality cuts and smooth edges, making them ideal for applications that require fine details and precision.

Fibre lasers, on the other hand, use a solid-state laser source to generate the laser beam. The laser light is transmitted through a flexible optical fibre, which allows for greater flexibility and efficiency. Fibre lasers are particularly well-suited for cutting metals, including steel, stainless steel, and aluminium. They offer several advantages over CO2 lasers, including higher cutting speeds, lower maintenance requirements, and the ability to cut reflective materials without the risk of damaging the laser source.

Nd:YAG lasers, or neodymium-doped yttrium aluminium garnet lasers, are another type of solid-state laser. They are less common in industrial cutting applications but are used for specialised tasks such as engraving and marking. Nd:YAG lasers are capable of delivering high peak power, making them suitable for applications that require deep and precise cuts. However, they are typically more expensive and have higher maintenance requirements compared to CO2 and fibre lasers.

Applications of Steel Laser Cutting in Various Industries

In the aerospace industry, precision is paramount, and laser cutting technology plays a crucial role in the fabrication of aircraft components. The ability to achieve tight tolerances and complex geometries ensures that parts such as turbine blades, structural components, and brackets are manufactured to the highest standards. Additionally, the efficiency of laser cutting reduces production times and costs, making it an essential technology for aerospace manufacturers.

The electronics industry also benefits greatly from steel laser cutting. The production of electronic components, such as circuit boards and enclosures, requires precise cuts and intricate designs. Laser cutting provides the accuracy needed to produce these components with minimal material waste. Furthermore, the non-contact nature of laser cutting ensures that delicate electronic components are not damaged during the manufacturing process.

Maintenance and Care for Laser Cutting Machines

Another important maintenance task is checking and replacing the air assist gas filters. The assist gases used in laser cutting, such as oxygen and nitrogen, are typically filtered to remove impurities that could affect the cutting process. Over time, these filters can become clogged and need replacement. Regularly inspecting and replacing the filters ensures that the assist gases are clean and effective, contributing to high-quality cuts.

Lubrication of the machine’s moving parts is also crucial for smooth operation. Components such as linear guides, bearings, and gears should be regularly lubricated according to the manufacturer’s recommendations. Proper lubrication reduces friction, minimises wear and tear, and extends the life of the machine. Additionally, performing regular inspections of the machine’s electrical components, cooling system, and laser source will help identify and address potential issues before they escalate into major problems.

Cost Analysis: Investing in Laser Cutting Technology

Operational costs are another important aspect to consider. These include the cost of consumables such as assist gases, replacement optics, and maintenance supplies. Additionally, the energy consumption of the machine can impact operational costs. Fibre lasers, for example, are known for their energy efficiency compared to CO2 lasers, which can result in lower electricity bills over time. It’s essential to evaluate the total cost of ownership, including both initial and ongoing expenses, to make an informed investment decision.

The return on investment (ROI) is a critical factor in the cost analysis. Laser cutting technology can significantly enhance productivity, reduce material waste, and improve cutting accuracy, leading to cost savings and increased profitability. By calculating the potential ROI based on factors such as increased production capacity, reduced labour costs, and improved product quality, businesses can determine whether the investment in laser cutting technology will deliver the desired financial benefits.

Future Trends in Steel Laser Cutting Technology

Another emerging trend is the development of hybrid laser cutting machines that combine the capabilities of different laser sources. For example, hybrid machines that integrate both CO2 and fibre lasers offer the versatility to cut a wide range of materials with varying thicknesses. This flexibility allows businesses to expand their cutting capabilities and take on diverse projects without the need for multiple machines.

Advancements in laser technology are also driving the future of steel laser cutting. Innovations such as ultrafast lasers, which emit extremely short pulses of light, enable even greater precision and minimal heat-affected zones. These lasers are particularly beneficial for cutting delicate and heat-sensitive materials. Additionally, the integration of artificial intelligence (AI) and machine learning into laser cutting systems is enabling predictive maintenance, real-time process optimisation, and improved cutting strategies, further enhancing efficiency and quality.

Conclusion: Choosing the Right Laser Cutting Machine for Your Business

Investing in laser cutting technology requires careful cost analysis to ensure that the benefits outweigh the expenses. By evaluating the initial and operational costs, as well as the potential return on investment, you can determine whether laser cutting technology is a viable option for your business. Staying informed about future trends in laser cutting technology will also help you stay ahead of the competition and take advantage of the latest advancements.

Ultimately, selecting the right laser cutting machine involves balancing your cutting requirements, budget, and long-term goals. By embracing laser cutting technology, your business can unlock new possibilities in metal fabrication, achieve unparalleled precision, and drive profitability. Whether you’re a small workshop or a large manufacturing facility, the right laser cutting system can revolutionise your approach to fabrication and position your business for success in a competitive industrial landscape.