How to Choose the Right CO2 Laser Cutter – 5 Things to Look out for

Here are 5 things to look for when deciding which laser cutter is right for you:

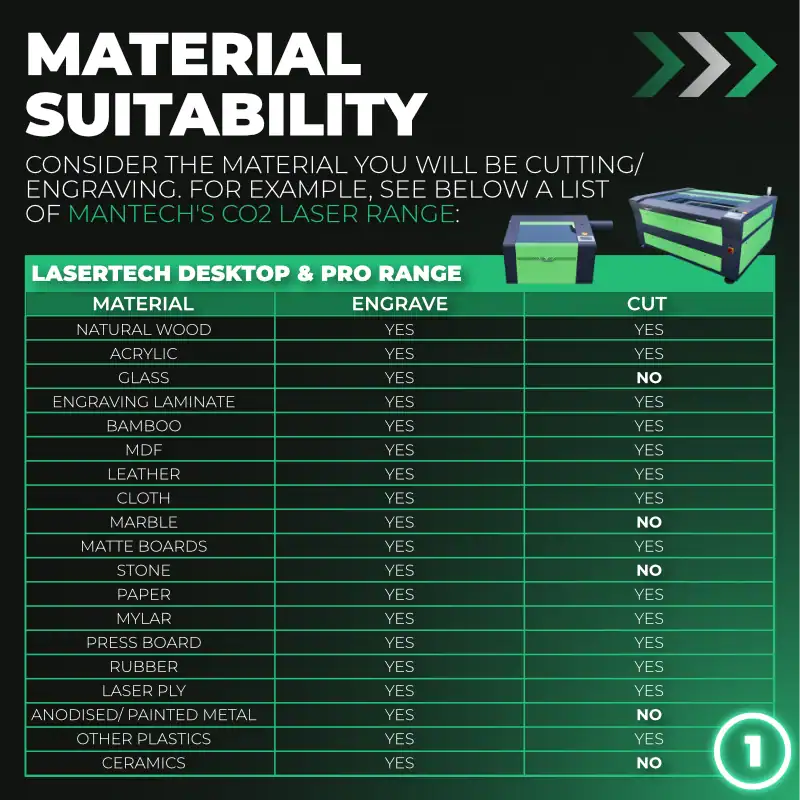

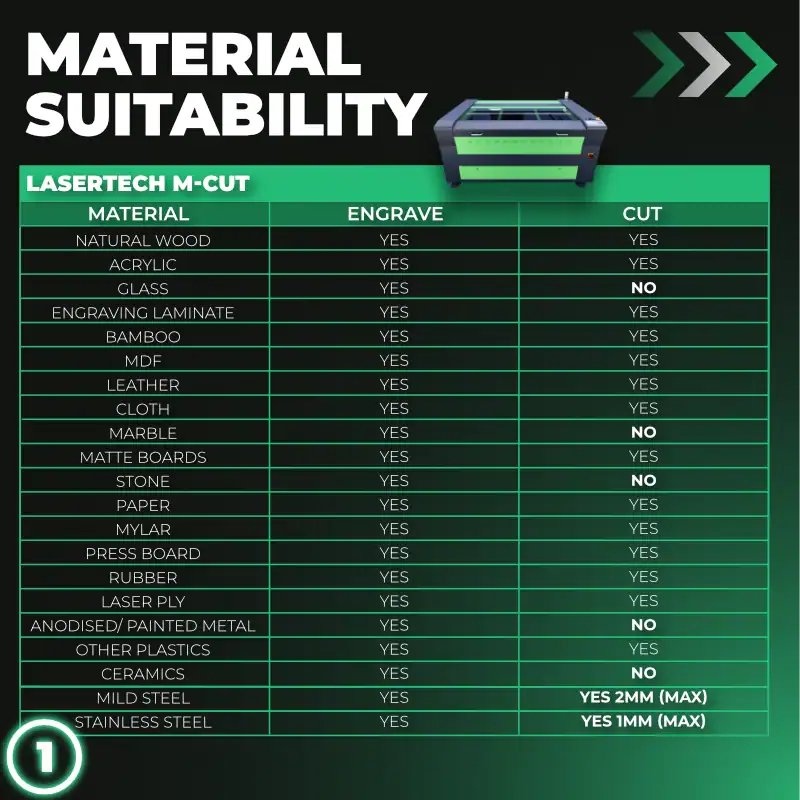

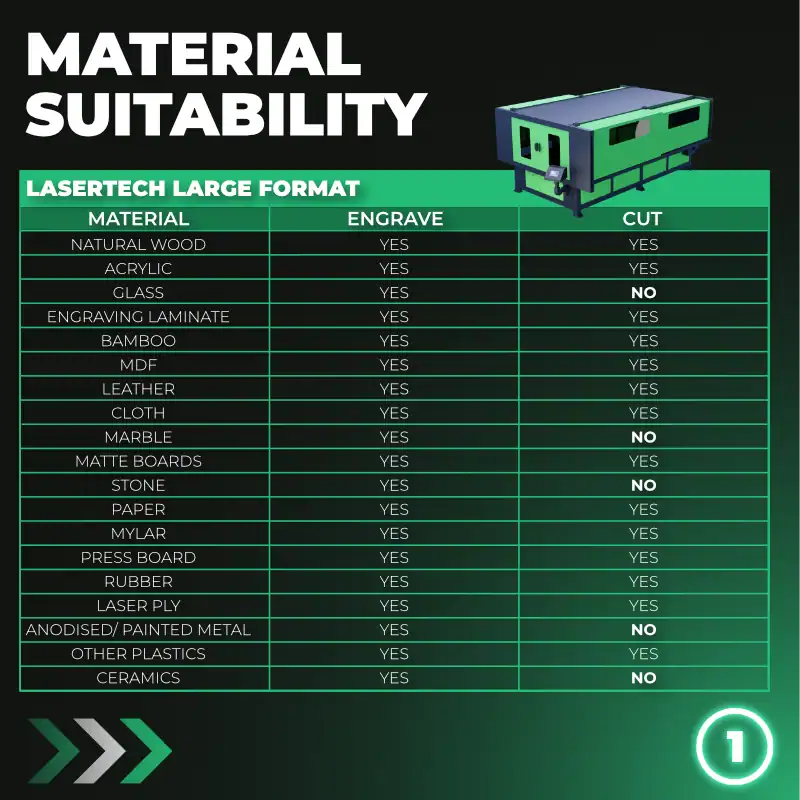

1. Material Sustainability & Compatibility

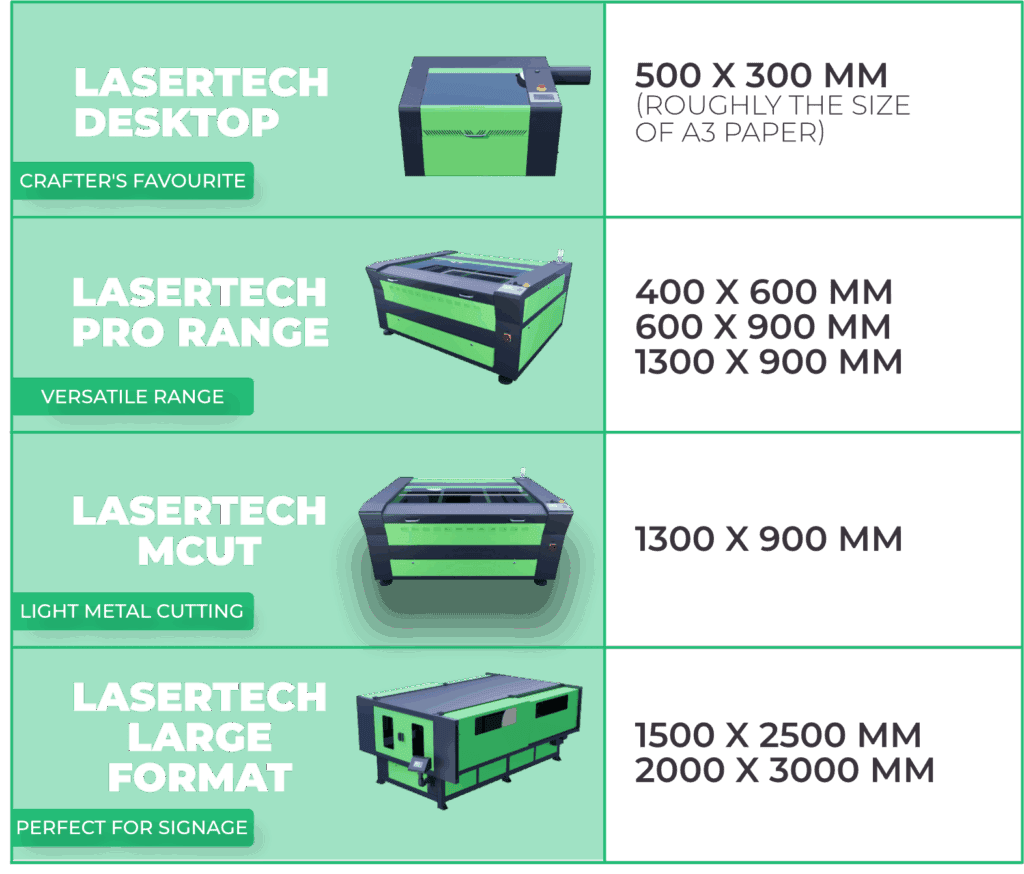

- Desktop CO₂ Lasers (80W, compact sizes like 300×500mm and 400×600mm) are ideal for schools, hobbyists, and small workshops. They handle woods, acrylics, leathers, textiles, and signage plastics with ease.

- Pro CO₂ Lasers (80W, larger beds up to 1300×900mm) are built for SMEs, offering higher throughput and the ability to take on bulkier work.

- Metal/Non-Metal CO₂ Lasers (150W, typically 1300×900mm bed) can cut non-metals just like the Pro range, but with added capacity for metals such as mild steel and stainless when paired with oxygen assist.

- Large Format CO₂ Lasers (150W, sizes like 1600×1000mm and 1300×2500mm) are designed for production-scale operations, processing bigger panels of acrylic, MDF, and other sheet materials in one pass.

Desktop CO₂ Lasers | Pro CO₂ Lasers | Metal/Non-Metal CO₂ Lasers | Large Format CO₂ Lasers

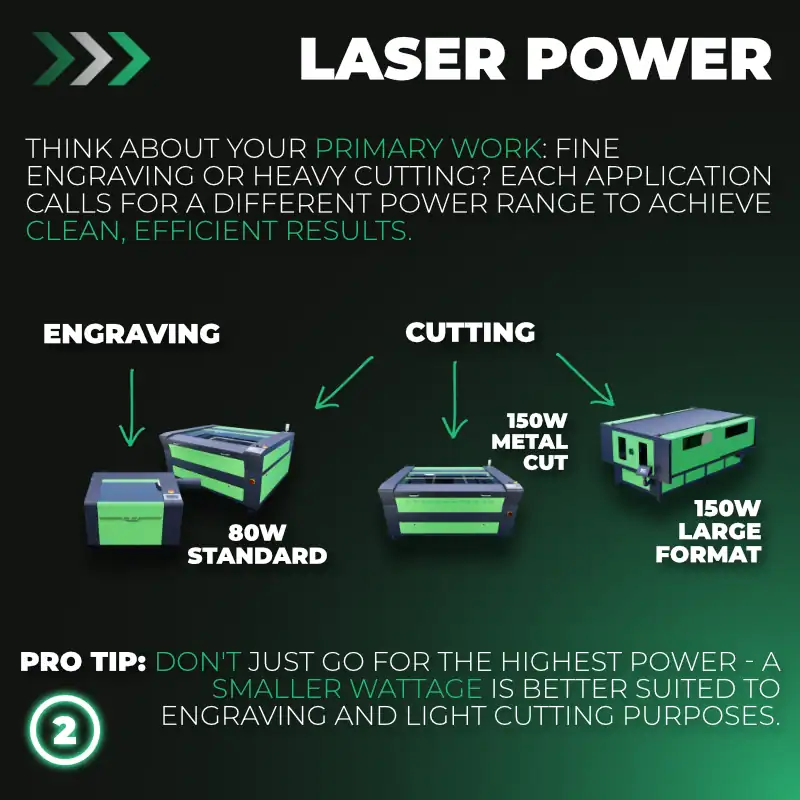

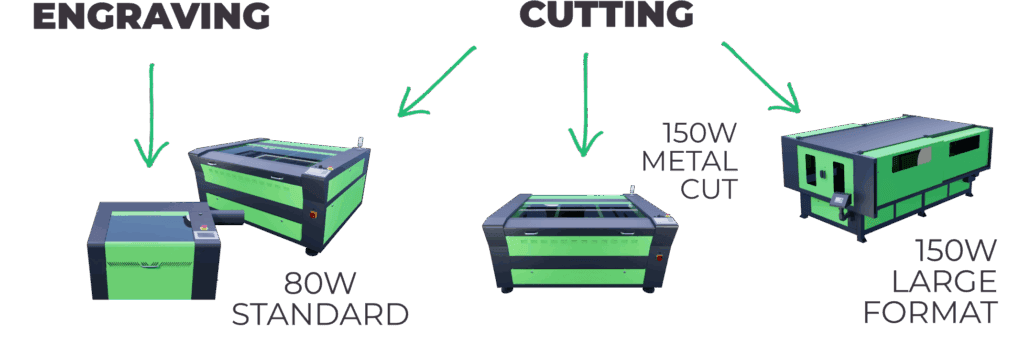

2. Laser Power – 80W vs 150W

- 80W models (Desktop & Pro ranges) are perfect for engraving and cutting up to medium-thickness woods, plastics, and laminates.

- 150W models (Metal/Non-Metal & Large Format) provide the extra cutting strength required for metals and thicker non-metallic sheets.

3. Bed Size – Choosing the Right Working Area

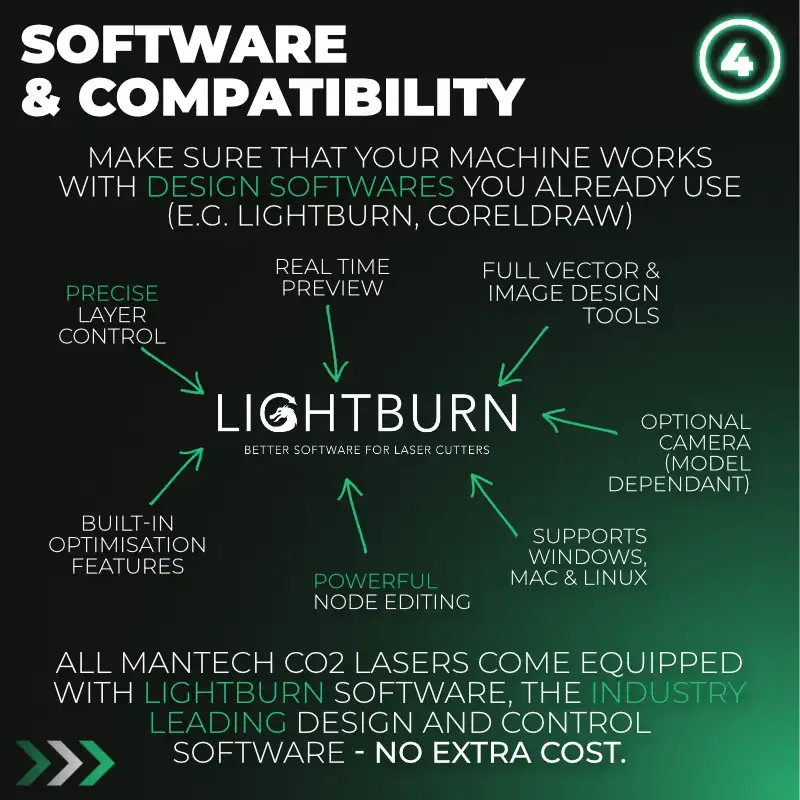

4. Software & Compatibility

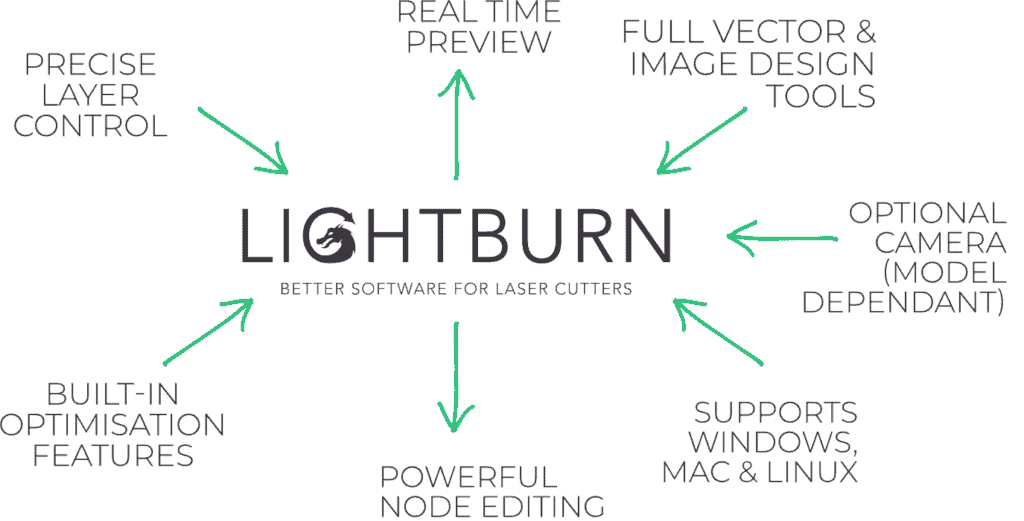

Mantech lasers run on LightBurn software, which is widely regarded as the industry standard. LightBurn enables you to design, nest, and run projects from a single interface with features such as advanced layer control, camera alignment, and compatibility with most design file types.

Other laser machines often use programs like RDWorks or LaserDRW. While functional, these can feel dated, with limited design tools, less intuitive interfaces, and slower processing. By comparison, LightBurn is modern, well-supported, and trusted by professionals worldwide — ensuring your team gets the most out of your machine from day one.

5. Supplier & Support

- Nationwide installation and training by our own engineers.

- UK & Ireland-based support with fast response times.

- Full aftercare and parts supply, from chillers and blowers to replacement optics.

- Included essentials like extractors, water chillers, and red-dot pointers for setup and operation.

UK: 0121 541 1444

Ireland: +353 83 804 8820

Or fill out a Quick Quote form and let us help you choose the right CO₂ Laser for your business.