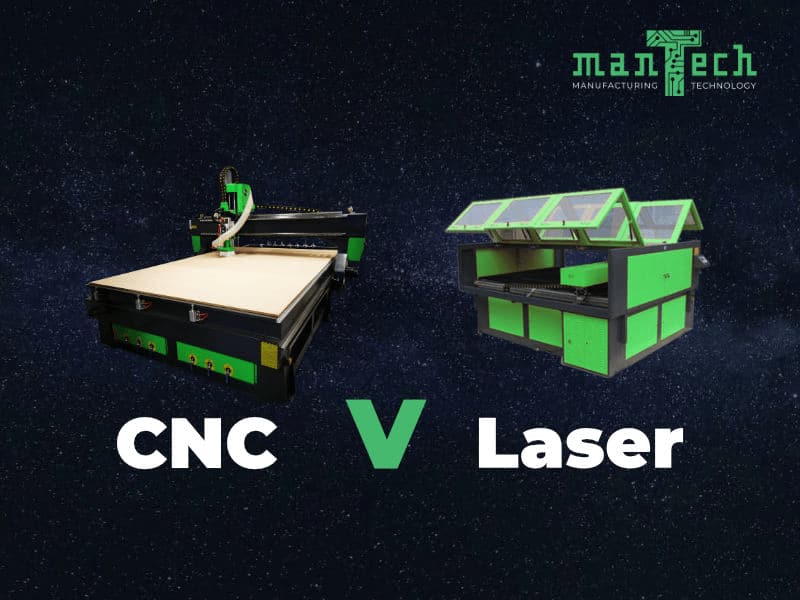

CNC Routers Or CO2 Laser Machines

We have been asked this question many times from our customers wanting to know which type of machine to use within their business. In some cases, there is a case for having both, but we’ll concentrate on the main differences between CNC routers and laser machines.

For some of you reading this article, you may not know how each of these machines works, let’s fix this first, for those of you who are fully aware of how each machine works, skip ahead by all means.

Let’s start with CNC router machines.

What is a CNC Router?

Often a CNC router consists of a sturdy metal framework that

has been tested under stress conditions for proper rigidity and strength. The frame will have a phenolic bed with a

matrix pattern routed out which enable the connected vacuum pump and filter

system to hold down a sacrificial layer (MDF) which in turn holds your material

via a negative pressure vacuum.

These CNC machines are often called goalpost CNC routers because they also have a gantry or ‘bridge’ which is raised at either side to enable it to move across linear rails in a backwards and forwards motion.

Connected to the gantry or bridge you will then have the head which moves left and right across similar linear rails, both movements give you your X and Y-axis. Connected to the head you will also have the heart of any CNC Router system, the spindle. Combined with the X & Y movement the Spindle is usually fixed to a Z-axis rail that enables the spindle to move in your up/down positions, these types of CNC router are also known as 3 axis CNC’s because they move in X, Y and Z.

Usually configured in a 3-phase mode for the best possible performance, however, they can be produced in single-phase where a 3-phase supply is not available.

Driven by motors with options such as a stepper, hybrid or servo drives, enabling high-speed movement of the gantry (bridge) across the material being cut. A very quick note on this, your speed of cutting will be dictated by material thickness, type and the tools you use.

A CNC router can process a multitude of material types such

as:

- MDF

- Plywood

- Hardwood

- Aluminium

- Brass

- Acrylic

- HDPE

- Polycarbonate

- Much more…

They are also provided with an extraction system to lift

away the swarf cut from your materials.

Some CNC routers have hand control units whereas others will use PC based systems to control the input and output of the machine. Alongside this there is a need for CAD/CAM software to design your file, apply toolpaths to it (so the CNC knows what speed and depth to cut or engrave) and export the gcode for the machine to read the set of co-ordinates so it knows where to process on your sheet of material. This may sound daunting at first, but you should receive training on the use of your new machine for both the software and the safe operation of the CNC router.

What is a CO2 Laser Machine?

CO2 Laser cutter and engraving machines are a very versatile machine, able to cut and engrave an array of materials such as acrylic, wood, card, paper, fabric, leather, rubber and much more. You do have to be careful with what you try to cut with a laser:

- PVC – you should never process this with a laser cutter as it forms hydrochloric acid

- Polycarbonate – cuts very badly

- MDF – unless it is of a very low formaldehyde type

- Any Plywood with a formaldehyde content

- Carbon fibre or fibreglass

- PTFE/Teflon

- PVB

- Materials containing halogens such as fluorine, bromine, chlorine, iodine

- Materials containing epoxy or phenolic resin

- This list is not exhaustive, and you should always speak with the manufacturer/supplier of your materials to ensure they are safe for laser cutting

The

materials above can, due to their chemical makeup, create dangerous dust or

gasses.

CO2 laser machines are built slightly different from a CNC router. The worktable is usually made up using a slat-based bed (removable) or a honeycomb bed type. CO2 lasers can also move in X, Y and Z – they have a bridge for the X & Y movements and model dependant, the bed will drop and raise to give you Z clearance.

The machines

are also either stepper or servo motor driven.

CO2 lasers work by using a high voltage power supply that sends power to

the sealed glass tube, which is cooled with water inside (constantly pumping through

a water chiller). The laser is generated

and fired around a series of mirrors and down through the laser head to the focussing

mirror – this then hits your material and depending upon speeds and power

settings your material will then be engraved or cut.

CO2 lasers

should also have a protective lid or cover to ensure the operator is safe from bouncing

rays when in operation, these lids should also, if lifted or opened, shut the

laser tube off to prevent injury.

Most lasers will also come with an extraction system which will be of a vent to atmosphere type or a dedicated self-contained air purification system that uses a series of charcoal filters – perfect for areas where a vent to the atmosphere cannot be used such as the classroom or office.

So, do you buy a CNC Router or CO2 Laser machine?

This isn’t

as simple as it first seems. There are

many factors that may sway your decision one way or the other.

Let’s go through the pros for CNC Routers:

- Extremely versatile

- Small to large cutting areas

available - A huge range of different tools

available – enabling you to cut and engrave different types of toolpaths such

as profile, drill, pocketing, engrave, v-cut, bevel, prism, 3d engraving. - Process thick materials with

(usually) a much higher gantry clearance than a CO2 laser. - Faster cutting speeds meaning shorter

production times - Automatic tool change options

- Automation and consistency of

produced parts - Reduce waste by nesting parts

Let’s go through the pros for CO2 Laser Machines:

- Material versatility

- Polished edge cuts when doing acrylic

in one pass (CNC routers you usually do 2 if you are not using a very expensive

polishing tool) - Reduced noise in operation over CNC.

- Excellent repeatability

- A range of tools is not needed to run

the machine - Reduced waste

- Cheaper initial purchase price

As with most products, there are some cons to consider when choosing between CNC routers and CO2 Laser Machines. Let’s see what they are:

CNC router cons:

- CNC routers can at times be loud

because of the vacuum pumps, extraction noise.

Material types can also cause an increase in noise pollution. - Even though CNC routers come with

extraction there will still be residual dust and swarf (especially if you are

using a compression tool forcing the swarf down into the cuts) that will need

to be cleaned away - Tool replacement – they don’t last

forever - Steeper learning curve – toolpaths, CNC

best practices CAD/CAM software - Loss of skilled labour, the machine does

most of the hard work (although this can also be classed as a pro point). - Tools – if you are cutting many types

of material, you will generally need a range of tools to do the job. - Higher upfront cost

CO2 Laser cons:

- Slower in operation

- Certain materials can be dangerous to

cut – check with your supplier - Can only cut and engrave – no fancy

cuts like on a CNC router - Burns the edges of certain materials

like wood – you would have to leave it or sand – creating an extra

manufacturing step - The laser tube, mirrors are all

consumable items and will require replacing at certain points in their lifetime

Conclusion

It’s safe to safe both types of

machinery are a fantastic addition to your manufacturing arsenal. Which one you should be using for your needs

relies on what your processes and restrictions may be within the workplace.

Do you want the versatility of a CNC

router with the types of tooling you can use, or do you want the simplicity of

a Laser cutter? Do you have noise restrictions

in the workplace area it will be used in?

Most of the time a CNC router will be

able to process jobs faster than a CO2 Laser but you are required to hold a

number of different cutters as opposed to only having the one source for

cutting and engraving on a laser machine.

There is also the use case for using both machines in the workplace should your manufacturing requirements need it. That way you get the best of both worlds, but, it can come down to individual business needs or need to produce a particular type of product.

Here at Mantech Machinery UK, we can help you make a decision based on our expert knowledge in the industry, looking at your business needs as to what may or may not be the best route to take when choosing a machine. We also offer all of our CNC and Laser machines on finance, please ask for details.

Our range of CNC routers consists of Merlin CNC Routers, Apollo ATC (auto tool change) CNC and our Entry Level range of CNC.