Quick Fibre Laser Welder Quote

Customer Quotation Form

Did you know, we now supply the brilliant Lightburn software for all laser cutters and engraving systems by Mantech (*excluding one model M-CUT which requires RDworks). read on to find out why Lightburn is a better choice for you and your business.

Lightburn is an incredibly superior and powerful editing, layout and laser control software that comes with many great features, enabling you to make light work of your laser cutter projects.

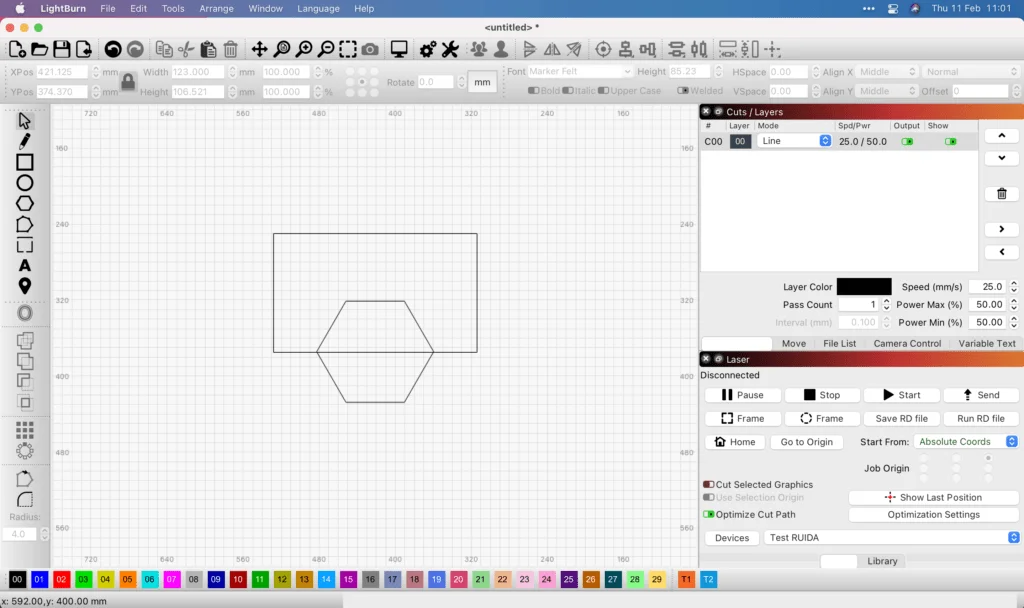

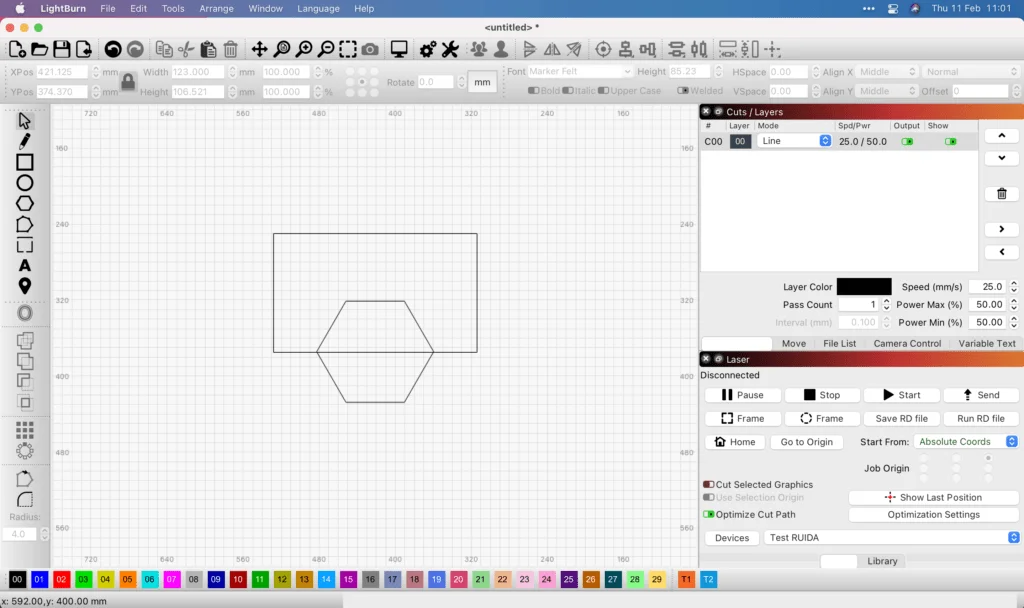

You can import a wide variety of formats into Lightburn such as AI, PDF, SVG, DXF, PLT, PNG, JPG, GIF, BMP. You can arrange, edit and even create brand new vectors right from within the user interface.

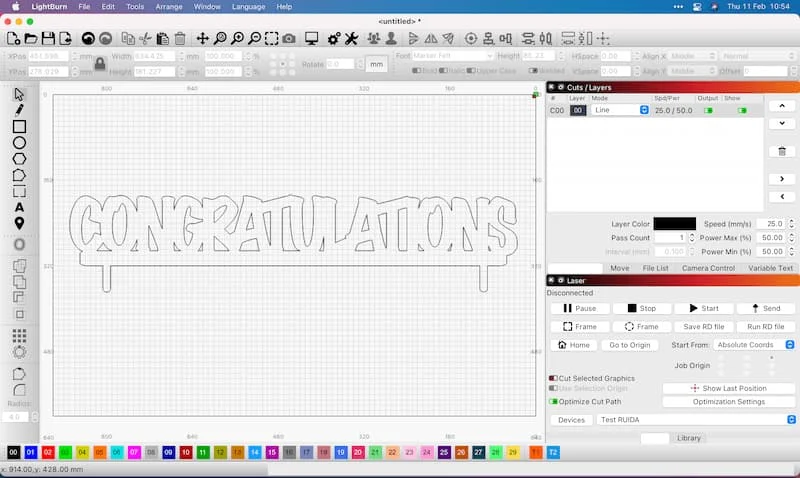

It has clean layout allowing you to get to grips with all aspects of the software extremely quickly, allowing you to concentrate on running your laser without being bogged down with inferior software.

With excellent compatibility across file formats, Lightburn is also fully compatible with Windows, Mac OS and Linux. Allowing you to use the operating system of your choice without having to use a separate system just for your Laser. One Lightburn license key unlocks the software permanently – you get 1 years free updates.

Lightburn comes with all the features you need to aid you in producing some real masterpieces on your Laser Cutter.

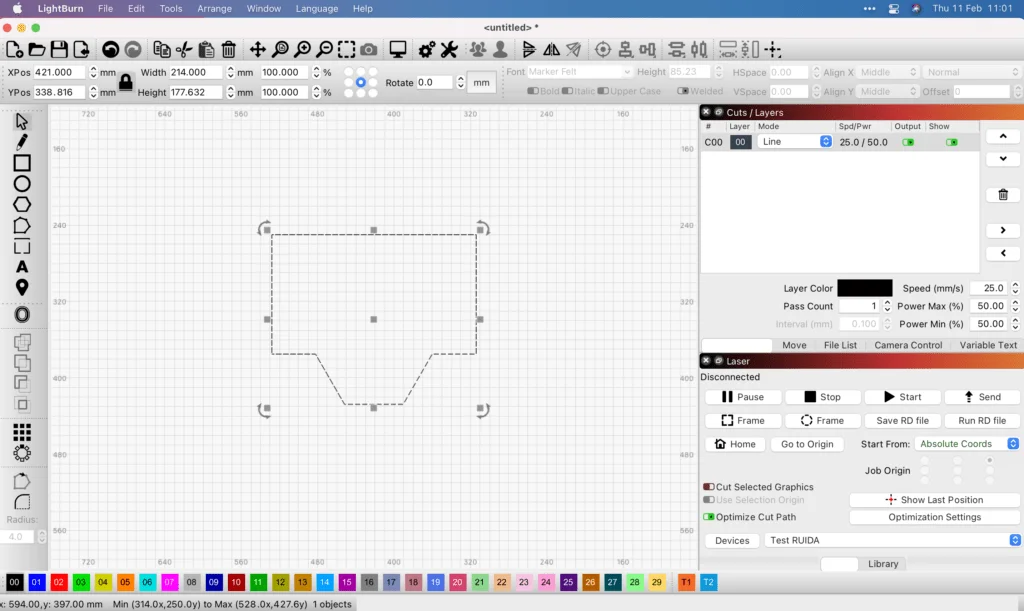

Control all aspects of your cutting and engraving settings, enabling you to get the perfect result.

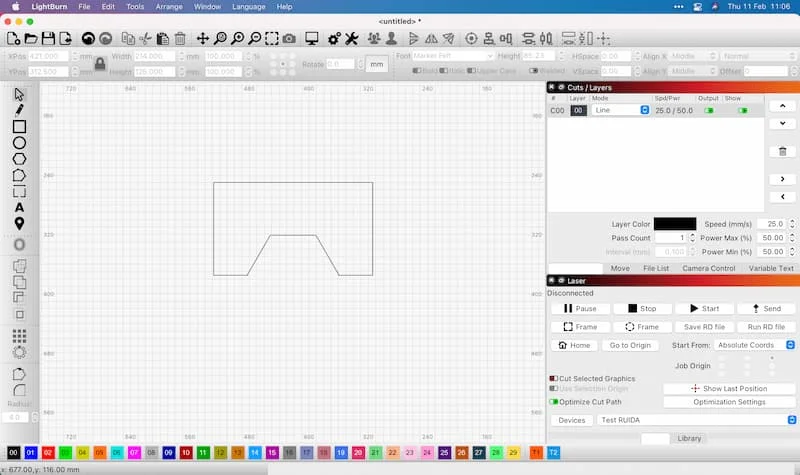

Create all types of vector shapes within the software and arrange using the built-in alignment tools. You can even group and weld lettering or shapes just like the above text.

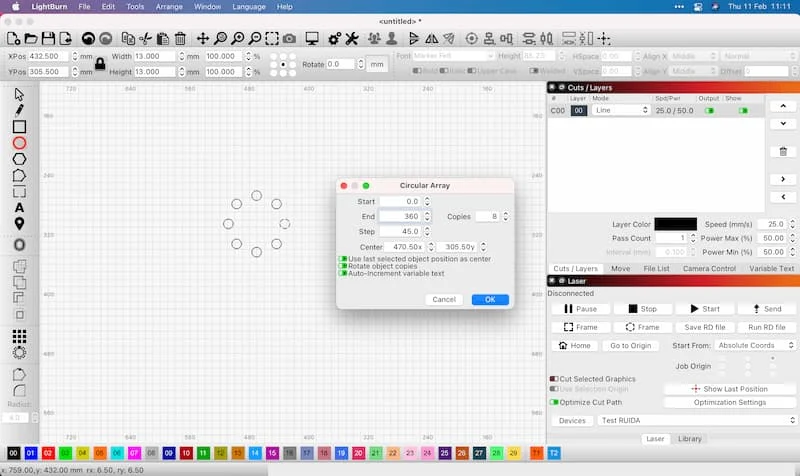

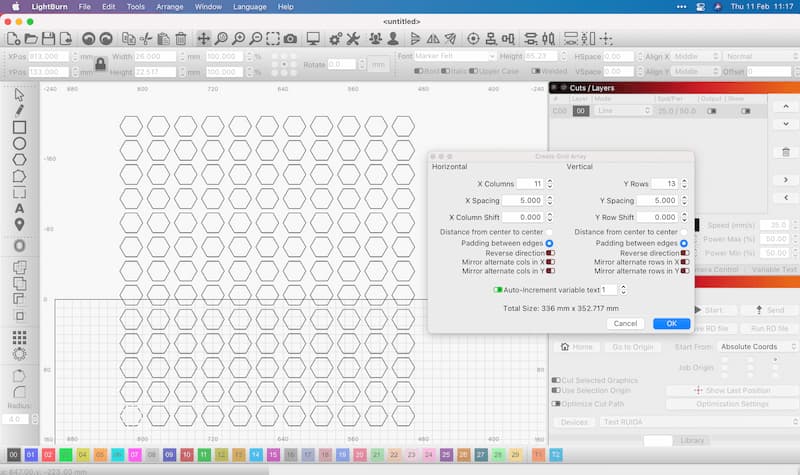

Its fast and easy to create multiple shape arrays in Lightburn with quite literally only a ‘few clicks’ of your mouse.

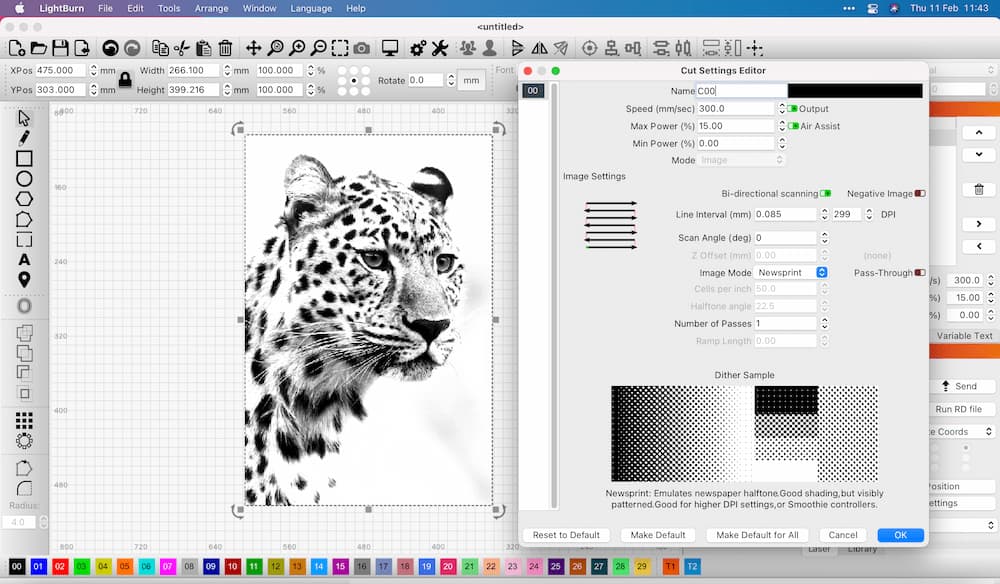

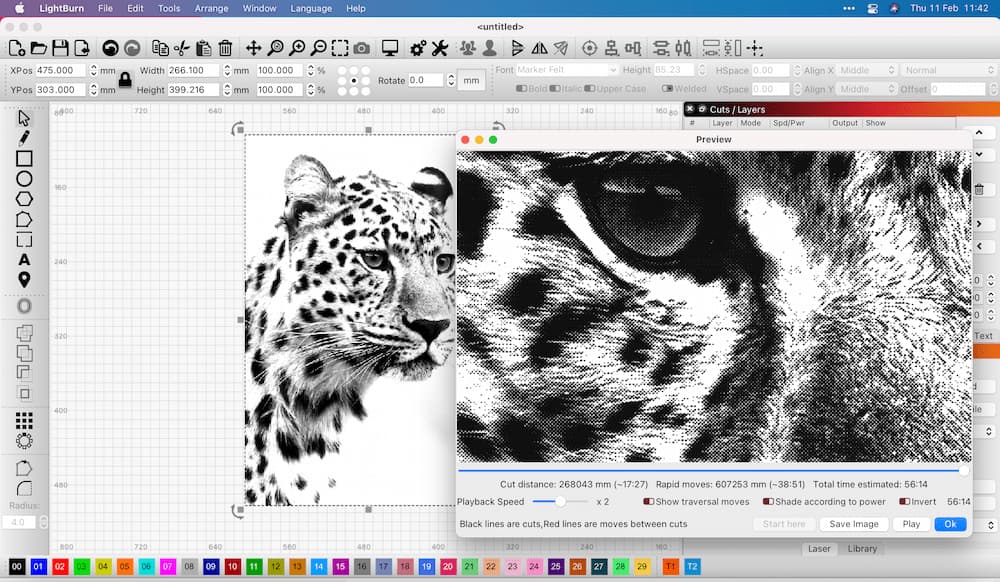

To create some of the very best results it is recommended to use a high contrast image. you can import jpg and BMP files right into Lightburn, the software automatically recognises that you have imported an image.

Right clicking on your image and choosing ‘properties’ panel will allow you to alter things like sharpness and contrast to get a better image prepared for engraving.

You can choose to apply settings for a variety of engraving methods such as Halftone, Greyscale, Sketch, Stucki, Jarvis and Newspaper.

If your system does not already come with a camera you can purchase them direct through Lightburn or Mantech. A camera system installed within your laser cabinet – giving you a real time view of your laser cutters bed but also allowing you to trace shapes/designs by capturing the data within Lightburn -you can then laser cut or engrave these vectorised designs onto your projects.

Having this capability also allows the user to capture the bed (with your material on) to easily enable you to position the head ready for cutting or engraving – reducing the need to create jigs.