Quick Fibre Laser Welder Quote

Customer Quotation Form

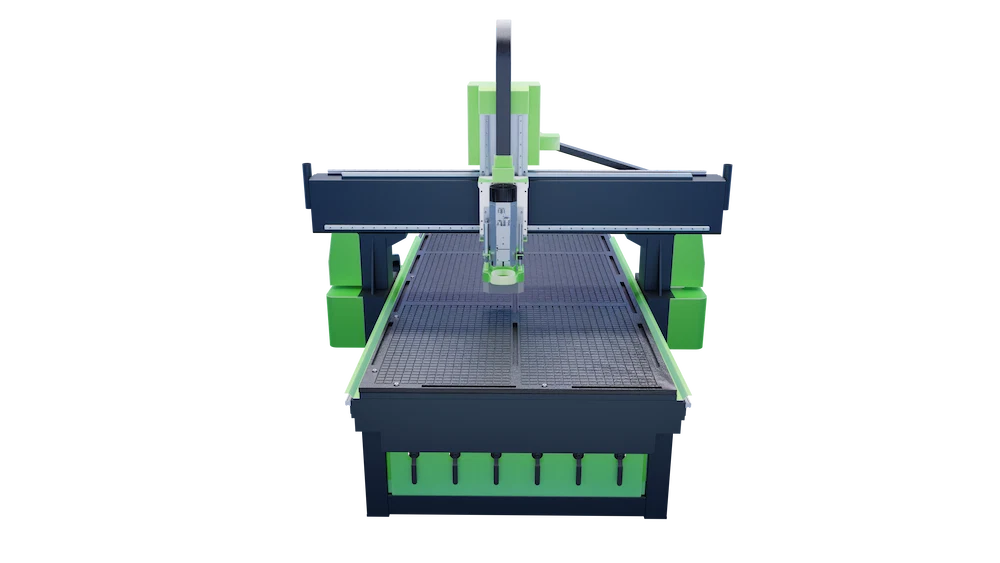

CNC machines allow for an amazing amount of production prowess. Available in a range of configurations and bed sizes CNC machines allow the end-user to produce impressive, highly accurate, repeatable projects in a wide range of materials and thicknesses.

There are many options available to you when thinking about purchasing your first CNC Machine, you should also take into consideration some of the pitfalls. Let us look at some of the options and reasons to choose them below.

Ideally, when it comes to bed size you should try to purchase a machine with the largest size that you envisage cutting in the future. Otherwise, you may be left with a machine where you have to outsource some of your work.

However, it may be that the work you do outsource is negligible and choosing a smaller bed for your core material sizes would suffice.

Do you need pop-up location stops for setting the position of your material? These help to ‘locate’ you’re sheets into the same position every time, great for repetitive projects.

One of the most important decisions is working out if your projects would require a full vacuum bed for material holding or a T-Slot clamping system. Some models of CNC machines also combine the best of both worlds and offer a combination system. On larger beds such as 10×5 ft and above the beds have an optimised layout for vacuum zoning and clamping, catering for popular sheet sizes.

Vacuum systems also require a vacuum pump or pumps depending upon surface area and utilise a sacrificial layer to allow you to machine on the surface without ruining your matrix vacuum bed.

The most popular type of CNC Machine by far is a 3 Axis system running in XYZ. However, there are other types that include an extra axis including the next most popular system that adds a fourth to your machine such as allowing the spindle head assembly to rotate around an object (check out our Apollo 4 Axis CNC Machine).

Using a 4 Axis CNC machine allows you to process materials from a horizontal position (especially when used with a pod and rail system like our Apollo 4 Axis machine), perfect for cabinet making and door manufacturing applications. However, if you don’t foresee yourself and your business undertaking this type of work or similar, then a 3 Axis CNC Machine would be a perfect choice, whilst also saving on the purchase cost.

Most CNC router Machine spindles are either water or air-cooled systems. The majority of our systems come with HQD branded air-cooled spindles such as our 6kW, 7.5kW and 9kW options. With the negation of water in the system, you don’t have to worry about checking water levels, and placing additives into the water chiller chamber (to prevent impurities and rusting), the simple fact is there is less maintenance on an air-cooled spindle over water-cooled.

With options from 18000rpm to 24000rpm and the above kW ratings, choosing the machine with the right kW rating for your material types is something our team of expert CNC router Machine specialists will assist you with.

CNC router machines come with a large number of different software and control system methods. The most common ways of controlling your machine are DSP hand control units which utilise a simple hand controller linked via a cable to your machine’s control card. The next popular method is by using a similar method of connection to the machine, but instead of a hand controller you have a graphical interface, either run by a PC unit or a self-contained podium with all of the relevant software to run all of the features within your CNC machine.

Here at Mantech, our CNC machines operate using both methods, depending upon which range you opt for. Spartan and Falcon use DSP control methods and our Apollo M, and Apollo ATC uses our own in-house developed CNC motion control system. We also operate well-known brands like Syntec for machines like our Apollo 4 Axis and Dual Bed systems.

All of our CNC machines come with CAD software, usually Vectric V Carve Pro (options such as Aspire and AlphaCam are also available).

As mentioned at the very start of this article, CNC router machines are extremely versatile, they give the end-user the ability to create a wide array of projects and are used in a huge number of industries. But what about the types of material you can process:

This list is not exhaustive, you can cut many more materials not listed

CNC router machines are perfectly placed to be used in a wide range of applications and industries. Here’s a short list below:

And so much more!!!

Build quality – CNC router machines use a large amount of rotational force and movement along the X and Y axis, having a robust well-built machine will ensure the accuracy of your projects.

Features – ensure the machine has all of the features you need to produce your products. Vacuum, T-slot only, Spindle types, control systems, extra axis etc.

Software – ensure the software on offer is capable of doing what you need it to do. Most companies will offer a number of solutions for you if needed (application dependant).

Safety – We ensure that all of our systems have the correct safety features implemented. Whether that’s based on electrical drawings from our R&D team to physical implementations in our UK warehouse.

Service – after-sales is as important as the sales process, and you need to make sure that you will be looked after well beyond the sales process is over. we pride ourselves on our after-sales service and invest heavily in both manpower and systems to ensure we are constantly improving and offer the best service to all of our customers, our reviews speak for themselves. Be wary of purchasing directly from abroad unless you have plenty of experience in doing so, after-sales may not be a top priority for some suppliers.

We also stock a large number of spares and parts for all of our machinery, right here in our factory in the UK.